Simple screw seat for internal combustion engine and manufacturing process thereof

A manufacturing process and screw seat technology, which is applied in the direction of screws, nuts, bolts, etc., can solve the problems of affecting the performance of screw seats, reducing the service life of screw seats, and the installation of screw seats is not firm enough, so as to ensure performance, improve service performance, The effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

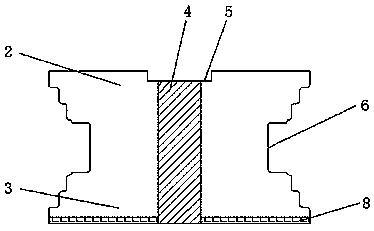

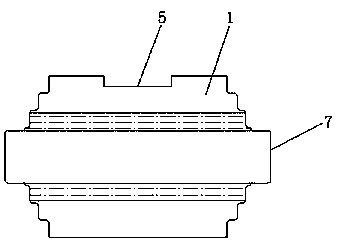

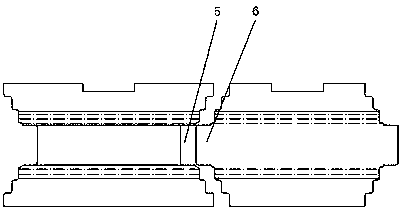

[0025] A simple screw seat for an internal combustion engine, comprising a screw seat 1, a screw hole 4, a groove 5, a mounting hole 6, a mounting block 7 and a heat insulation layer 8, the screw seat 1 includes an upper base 2 and a lower base 3, the The bottom of the upper base 2 is provided with a lower base 3, and the middle part of the screw seat 1 is provided with a screw hole 4, and the inside of the screw hole 4 is provided with an internal thread, and the middle of the top of the upper base 2 is provided with a screw hole 4. The position is provided with a groove 5, the left and right sides of the screw seat 1 are provided with mounting holes 6, the front and rear of the screw seat 1 are provided with mounting blocks 7, and the mounting blocks 7 and the mounting holes 6 are compatible with each other, the bottom of the screw seat 1 is provided with a heat insulating layer 8, the upper base 2 and the lower base 3 are an integrated connection structure, and the bottom of...

Embodiment 2

[0033] A simple screw seat for an internal combustion engine, comprising a screw seat 1, a screw hole 4, a groove 5, a mounting hole 6, a mounting block 7 and a heat insulation layer 8, the screw seat 1 includes an upper base 2 and a lower base 3, the The bottom of the upper base 2 is provided with a lower base 3, and the middle part of the screw seat 1 is provided with a screw hole 4, and the inside of the screw hole 4 is provided with an internal thread, and the middle of the top of the upper base 2 is provided with a screw hole 4. The position is provided with a groove 5, the left and right sides of the screw seat 1 are provided with mounting holes 6, the front and rear of the screw seat 1 are provided with mounting blocks 7, and the mounting blocks 7 and the mounting holes 6 are compatible with each other, the bottom of the screw seat 1 is provided with a heat insulating layer 8, the upper base 2 and the lower base 3 are an integrated connection structure, and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com