High-efficiency sand baking device used for quartz sand

A high-efficiency, quartz sand technology, used in heating devices, drying solid materials, non-progressive dryers, etc., can solve the problems of uneven baking and slow baking efficiency, and achieve uniform baking and high baking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

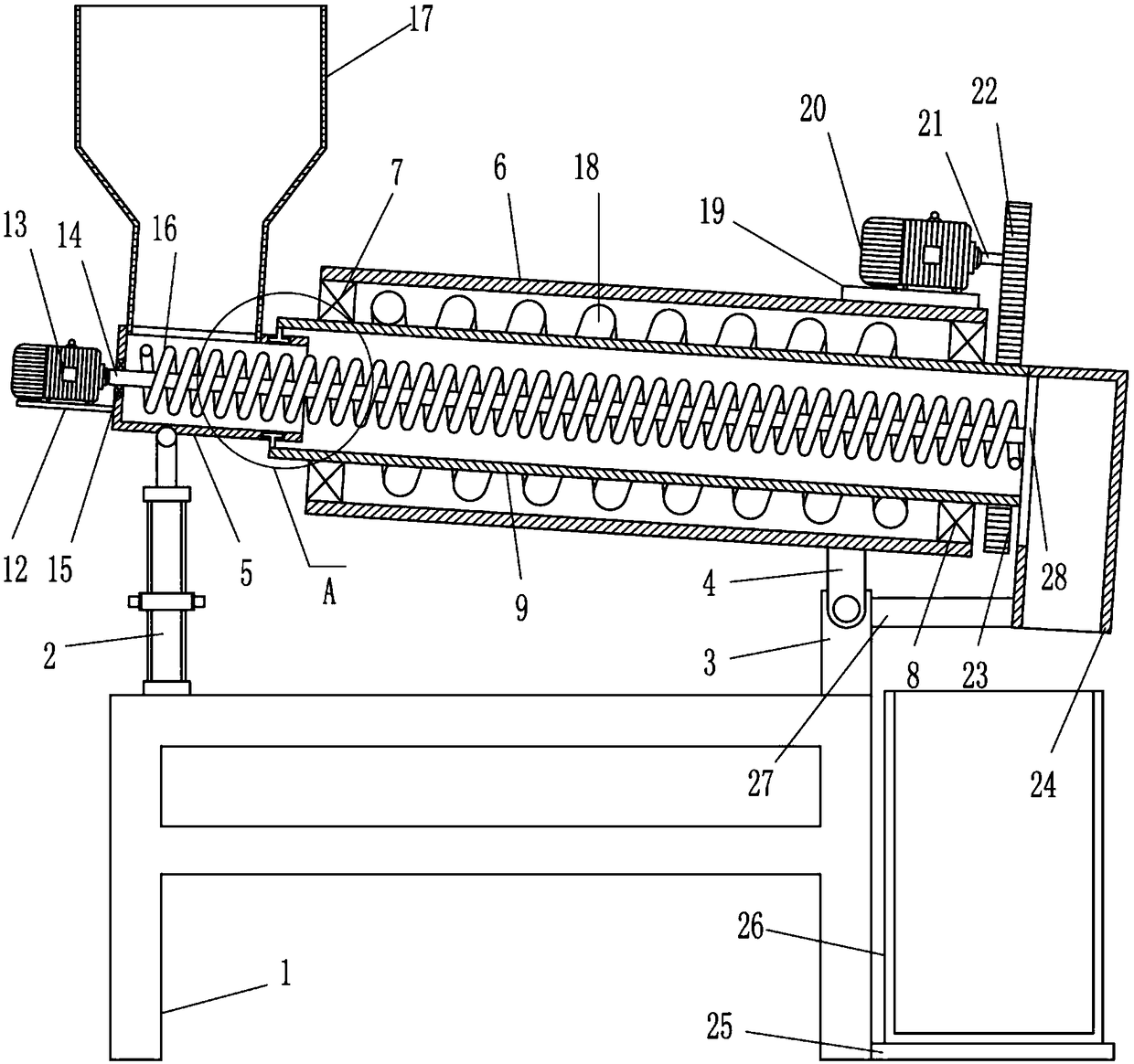

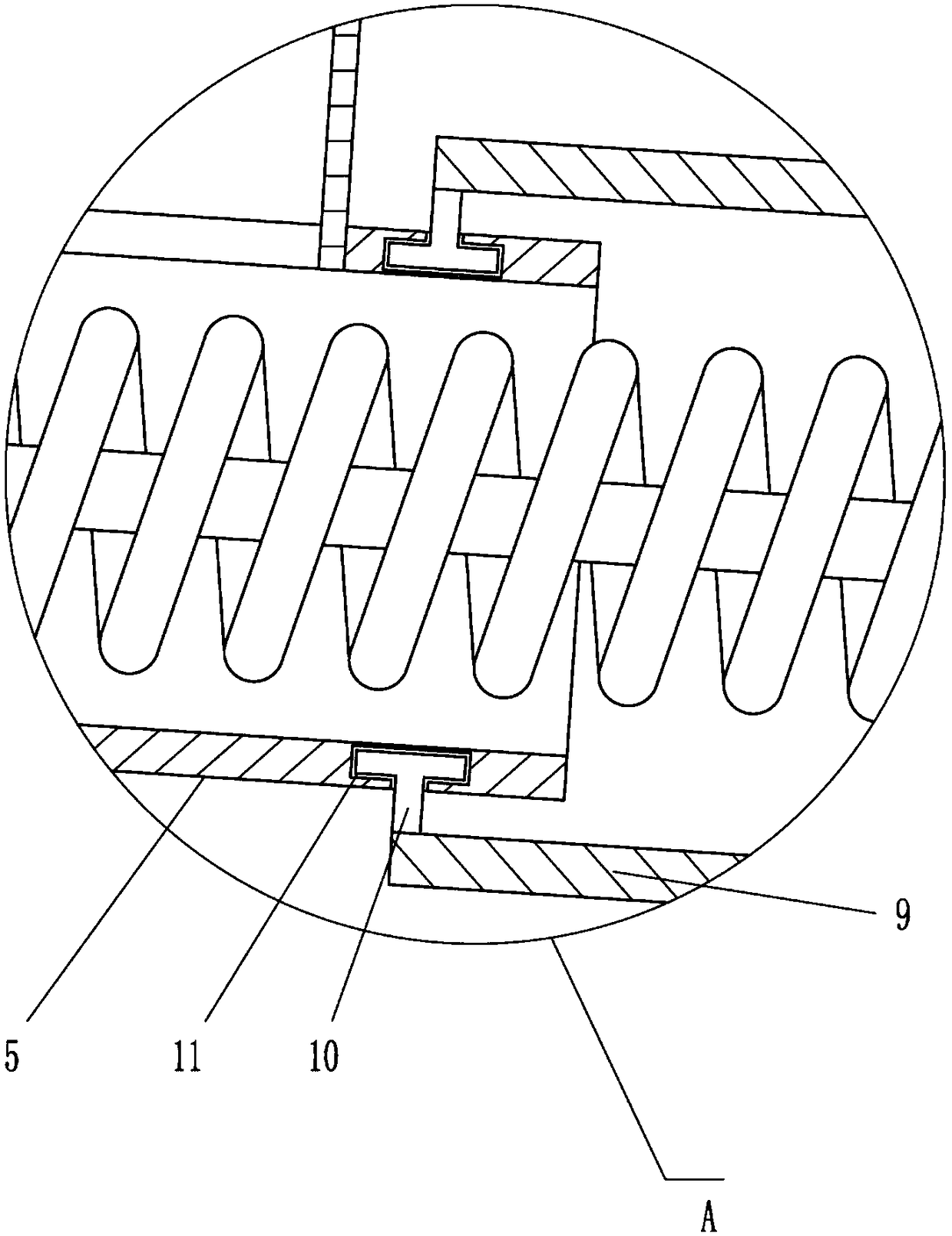

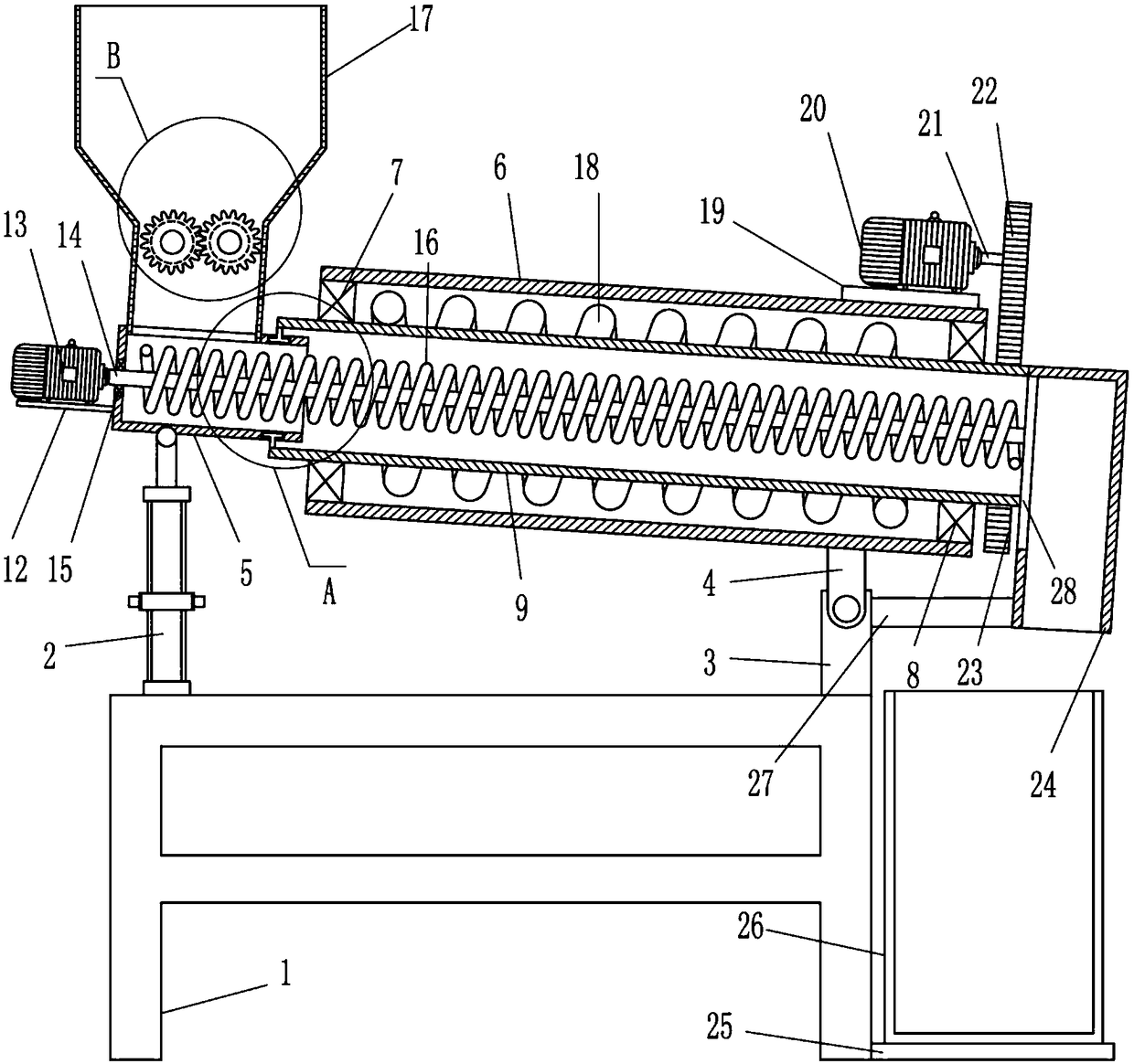

[0025] A high-efficiency baking sand device for quartz sand, such as Figure 1-6 As shown, it includes a base 1, a telescopic cylinder 2, a support 3, a hinge 4, a mounting cylinder 5, a baking oven 6, a first bearing seat 7, a second bearing seat 8, a baking tube 9, and an annular slider 10 , the first mounting plate 12, the first motor 13, the first rotating shaft 14, the third bearing seat 15, the first tungsten gold carbon fiber heating coil 16, the hopper 17, the second tungsten gold carbon fiber heating coil 18, the second mounting plate 19 , the second motor 20, the second rotating shaft 21, the first gear 22, the second gear 23, the installation frame 24, the placement plate 25, the container 26 and the support 27; The bottom is hinged to the output end of the telescopic cylinder 2, the support 3 is fixed to the top of the base 1, the bottom of the oven 6 is hinged to the top of the support 3 through the hinge 4; one side of the oven 6 is embedded with a first bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com