Testing pit for single package test and stacking test of explosive

A technology of explosives and test pits, which is applied in the direction of material explosion, can solve the problems of no operating platform, easy fragmentation and disintegration, high labor costs and time costs, etc., to prevent safety risks, low construction costs, and construction simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

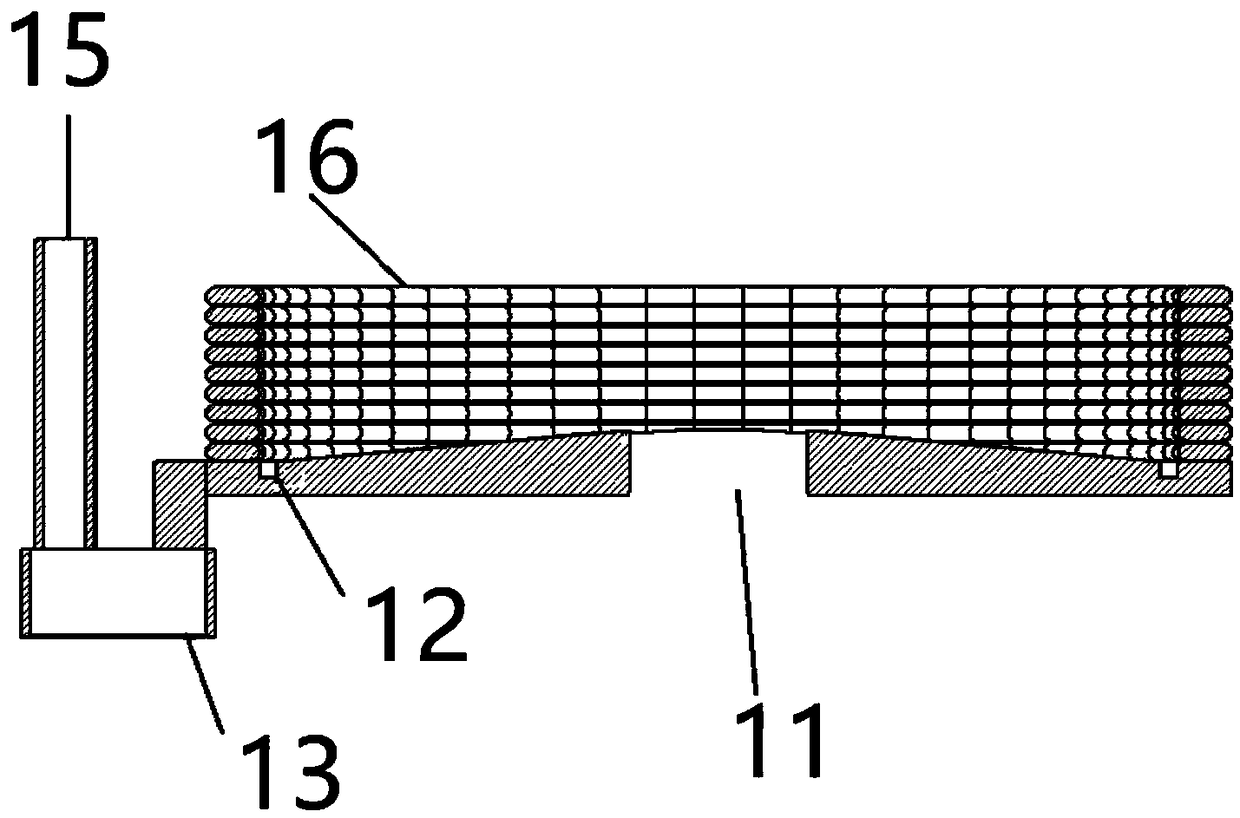

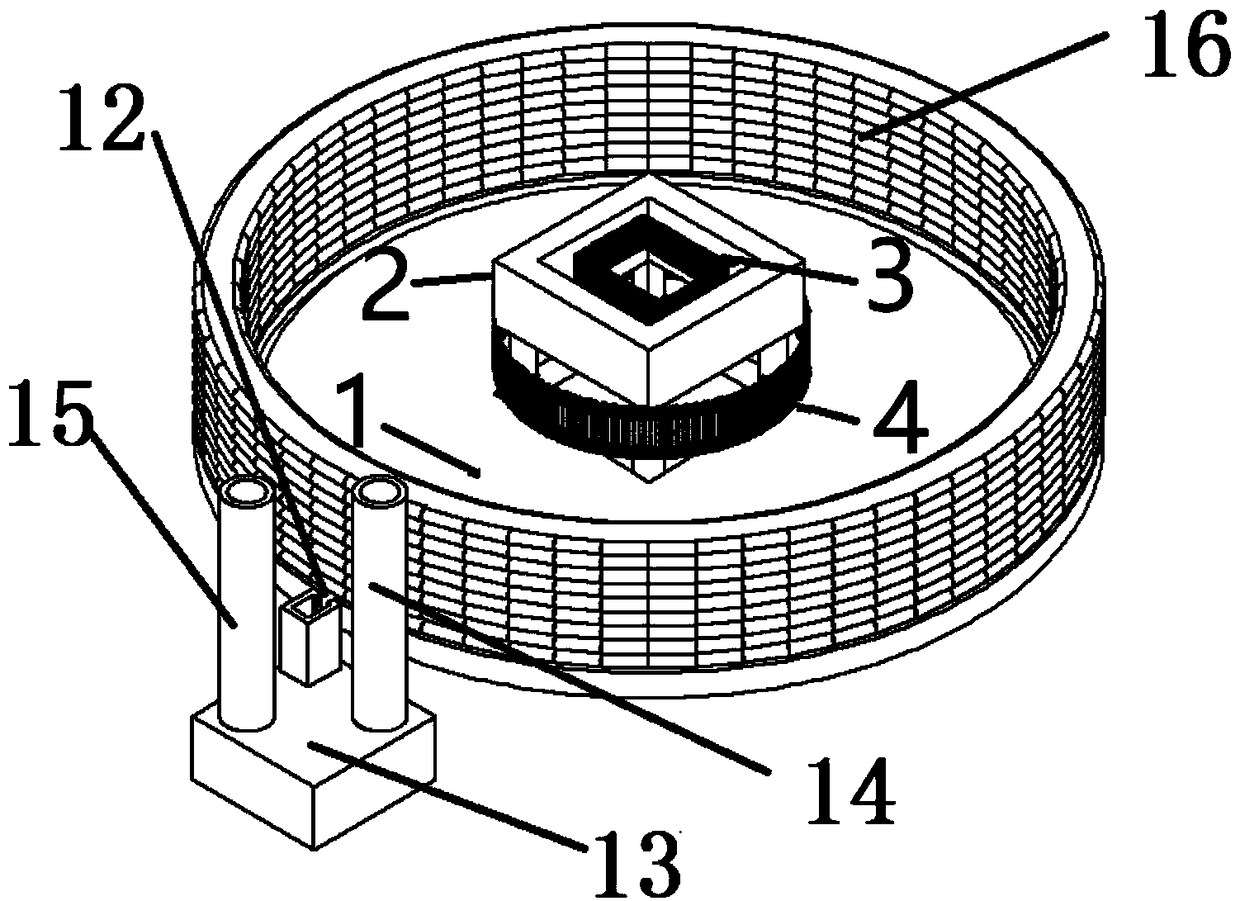

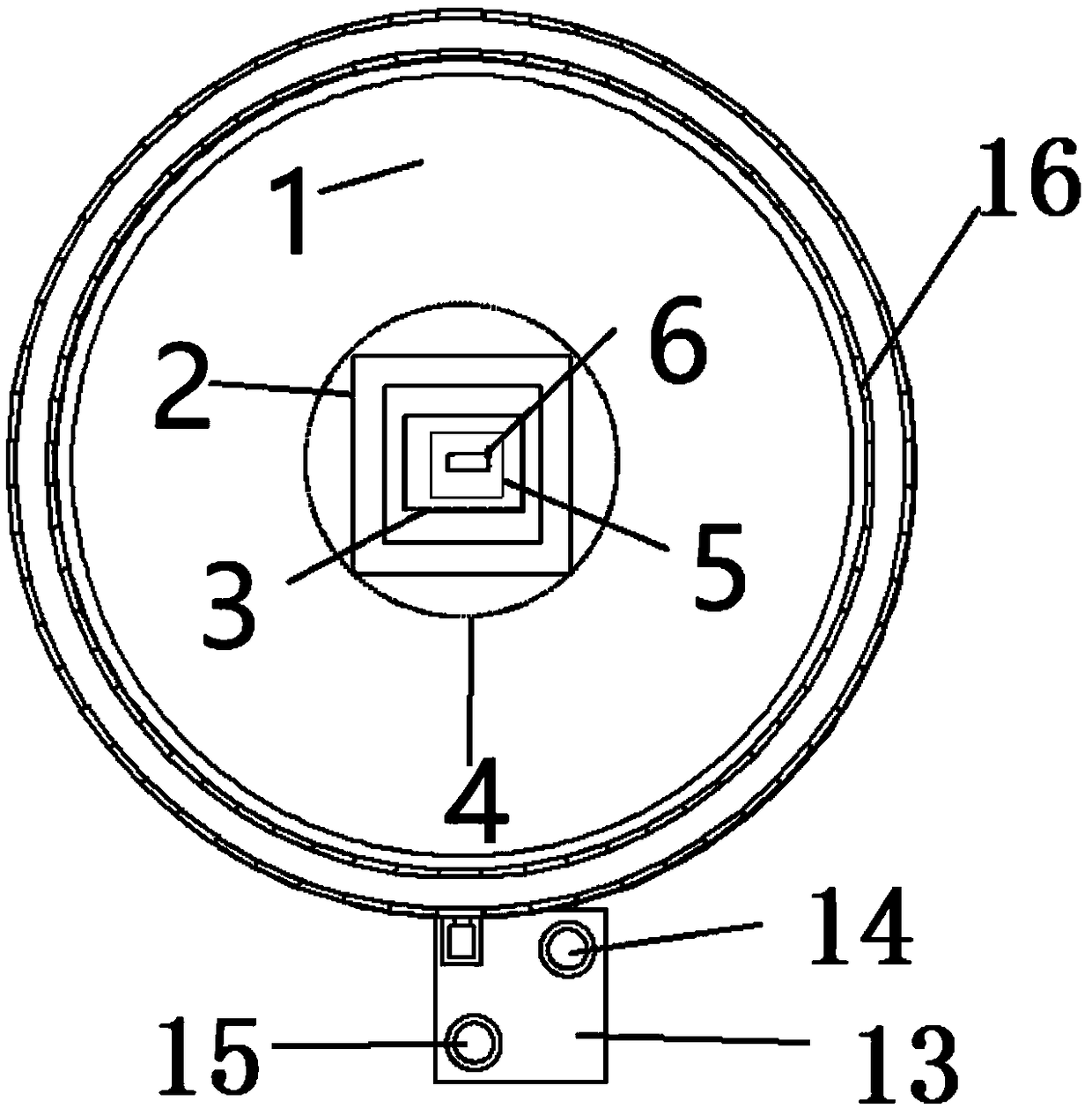

[0039] A test pit for single package testing and stacking testing of explosives (e.g. Figure 1-4 shown), including deep pit 1, operating platform 2, boundary wall 3, and barbed wire 4; operating platform 2 is set at the center of deep pit 1; barbed wire 4 is set inside of operating platform 2; external.

[0040] The operating platform 2 is a square frame, and four triangular legs 21 are arranged under the four top corners of the operating platform 2; one of the corner tips of the triangular legs 21 points to the center point. The bottom end of the triangular leg 21 is provided with an anti-settling plate 23 . The vertical direction of the boundary wall 3 is a rigid structure, and the horizontal direction is a flexible structure. A horizontal mark 22 is provided on the triangular leg 21 . The barbed wire 4 forms a circle along the triangular leg 21, and its height is consistent with the height of the triangular leg 21, which is circular. The aperture of barbed wire 4 is 1c...

specific Embodiment approach

[0041] 1. Construction of the test pit

[0042] Build a deep pit 1 with a diameter of 11m and a depth of 2m. The bottom is rammed with soil and trimmed to a slope slightly higher in the middle and gradually inclined to the edge. The center of the bottom of the pit is dug out 5m 2 central pit. Pave the bottom of the pit with concrete, and the central deep pit forms a square through hole 11 in the middle of the bottom of the pit. Build 40cm wide circumference drainage ditch 12 on the edge of pit, build 60cm wide slope protection stacking boards outside the drainage ditch. Build a drainage pit 13 lower than the bottom of the pit next to the deep pit, so that it communicates with the drainage ditch. Build two through holes protruding from the ground on the drainage pit, one is a vent hole 14 for communicating with the atmosphere, and the other is a drainage hole 15 for hanging the submersible pump. Set up iron fences at the junction of the drainage ditch and the drainage pit to...

Embodiment 2

[0051] A test pit for single package test and stacking test of explosives, including deep pit 1, operating platform 2, boundary wall 3, and barbed wire 4; operating platform 2 is set at the center of deep pit 1; barbed wire 4 is set at the center of operating The inside of the platform 2 ; the boundary wall 3 is set outside the operation platform 2 .

[0052] The operating platform 2 is a square frame, and four triangular legs 21 are arranged under the four top corners of the operating platform 2; one of the corner tips of the triangular legs 21 points to the center point. The bottom end of the triangular leg 21 is provided with an anti-settling plate 23 . The vertical direction of the boundary wall 3 is a rigid structure, and the horizontal direction is a flexible structure. A horizontal mark 22 is provided on the triangular leg 21 . Barbed wire 4 forms a circle along triangular leg 21, and its height is consistent with the height of triangular leg 21, is square. The apert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com