A high temperature resistant cable for electrical control

A technology of electrical control and high temperature resistance, applied in the field of high temperature cables, can solve the problems of inability to transmit signals or electrical energy normally, cable insulation aging, scorch, etc. Enhanced wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

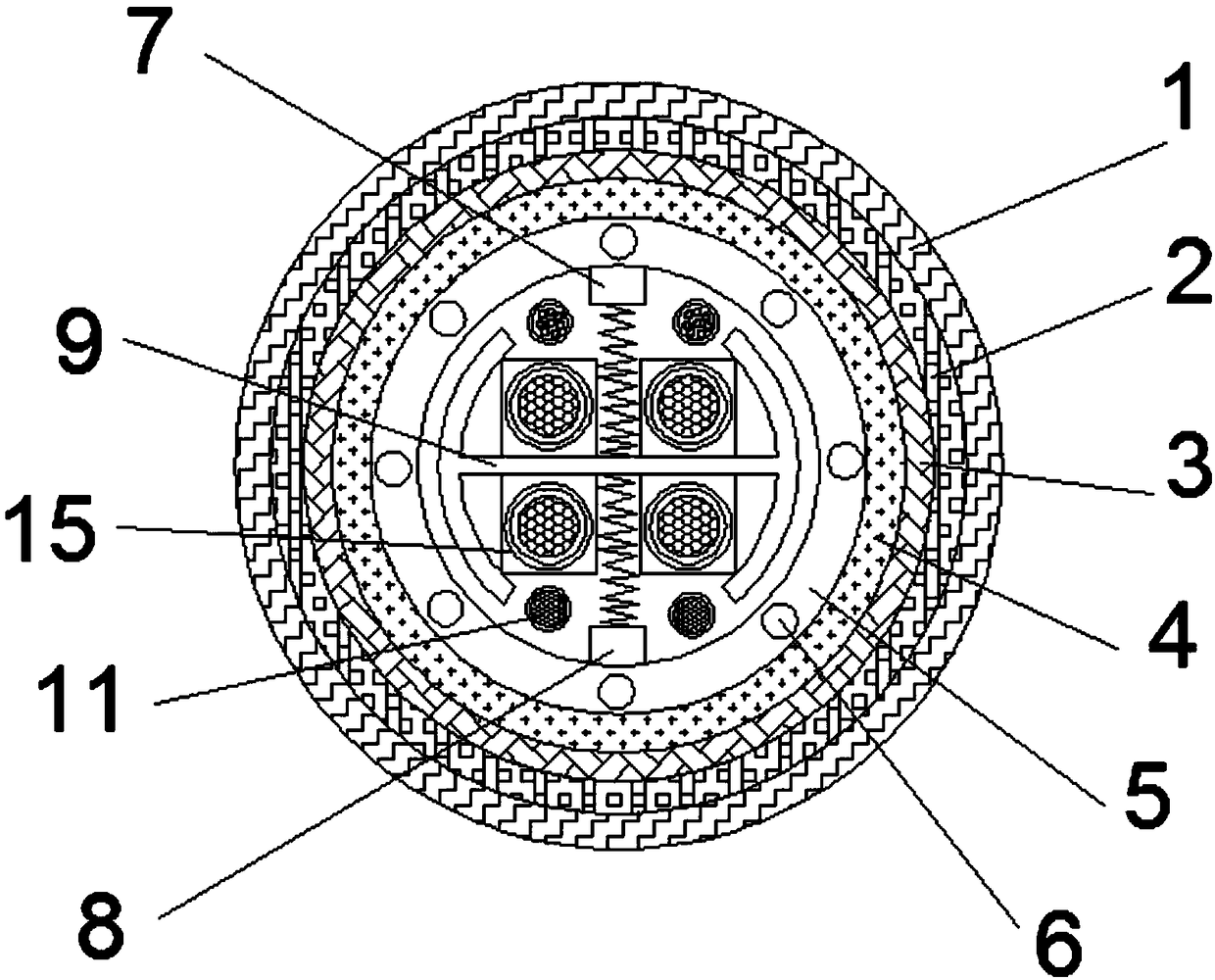

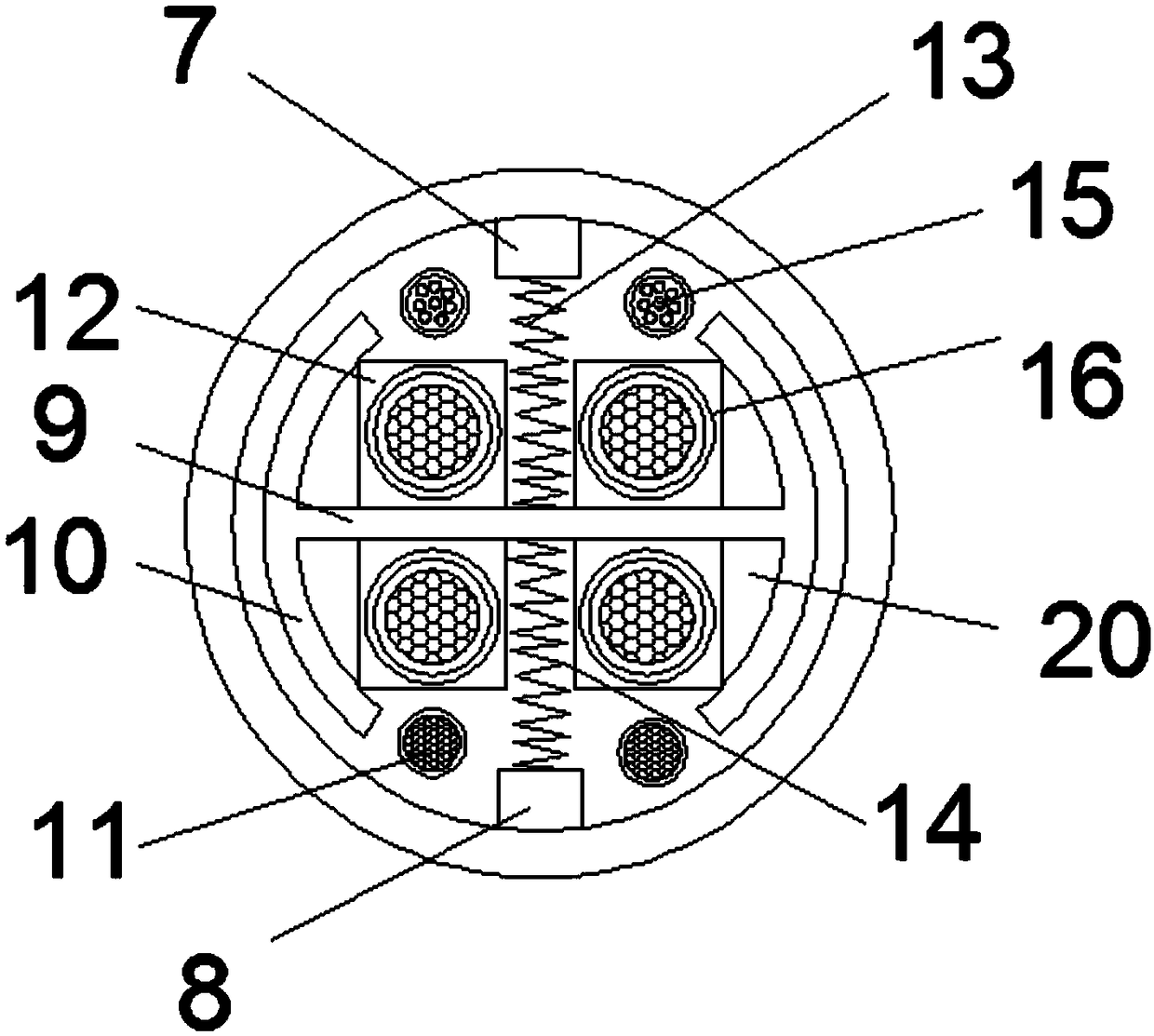

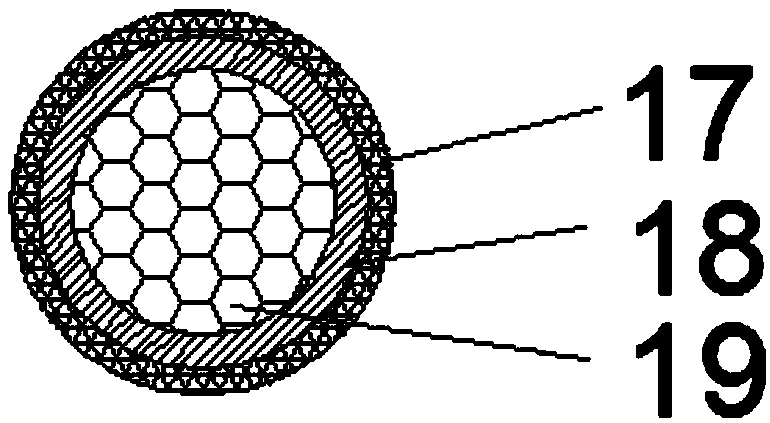

[0020] Such as Figure 1-Figure 3 As shown, the present invention proposes a high-temperature-resistant cable for electrical control, including a protective layer 1, a heat dissipation plate 9 and a cable body 16, the inner side of the protective layer 1 is provided with a fire-proof and heat-insulating layer 2, and the inside of the fire-proof and heat-insulating layer 2 is provided There is a shielding layer 3, the inner side of the shielding layer 3 is provided with an insulating layer 4, the inner side of the insulating layer 4 is provided with a traction layer 5, the center of the inner side of the traction layer 5 is provided with a heat dissipation plate 9, and the left and right ends of the heat dissipation plate 9 are provided with heat dissipation arcs 10, The middle part of the upper end of the cooling plate 9 is provided with a first spring 13, and the other end of the first spring 13 is fixedly connected with the inner wall of the traction layer 5 through the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com