Water-in-oil type emulsion

A water-in-oil, emulsion technology, used in cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problem of reduced use feeling, dosage form viscosity and hardness phase separation, difficulty in preventing emulsion particles from coagulation, fusion, and emulsion separation. layer and other problems to achieve the effect of improving the stability of the dosage form and preventing the agglomeration of emulsified particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

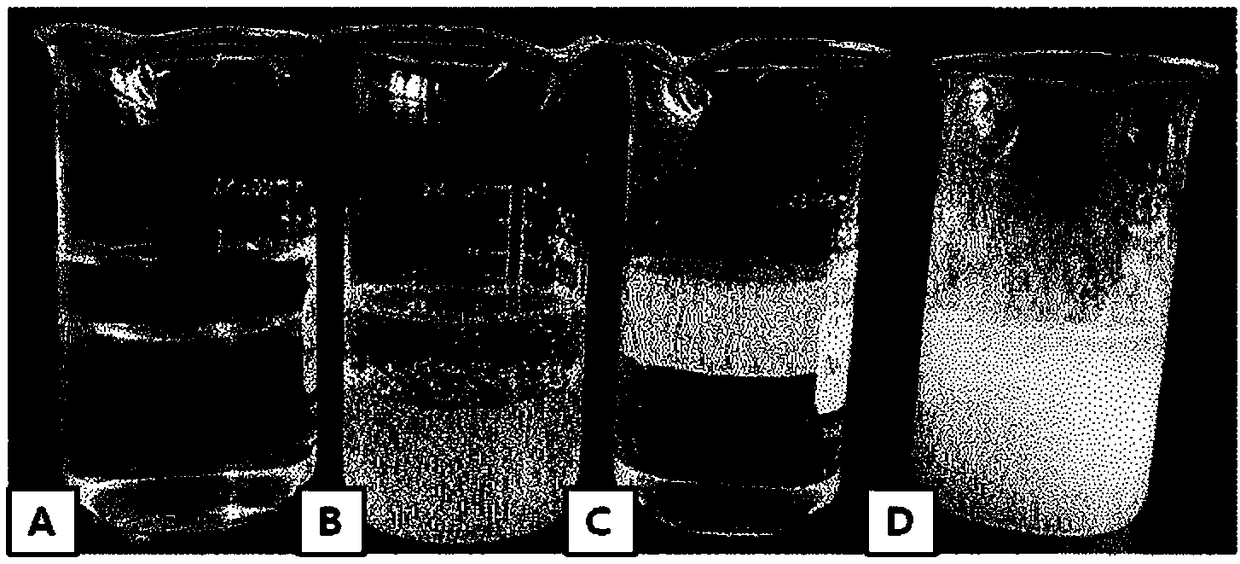

[0045] According to the composition described in the following Table 1, a water-in-oil emulsion was prepared by a conventional method, and each component was added in % by weight based on the total weight of the emulsion. More specifically, after mixing the water phase and the oil phase separately, the water phase is added to the oil phase and mixed.

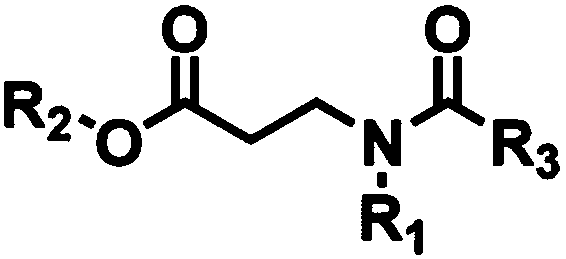

[0046] In this case, compounds A and B are amine-containing compounds, compound A is hexyldecyl myristoyl carbamate, compound B is aminopolydimethylsiloxane, and compounds C, D, E, and F are Anionic polymer compound, compound C is acrylate / C10-C30 alkyl acrylate crosslinked polymer, compound D is polyacrylic acid, compound E is alginic acid, and compound F is polystyrenesulfonic acid. Lauryl polyethylene glycol-10 tris(trimethylsiloxy)silylethyl dimethicone was used as surfactant.

[0047] In addition, compared with the amount of commonly used surfactants, experiments were carried out by using a small amount of surfactants to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com