Snap-in device, vehicle hinge including the snap-in device and method of using the snap-in device

A buckle device and hinge technology, applied in construction, door/window accessories, wing leaf parts, etc., can solve the problems of door stopper wear, particle formation, etc., and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

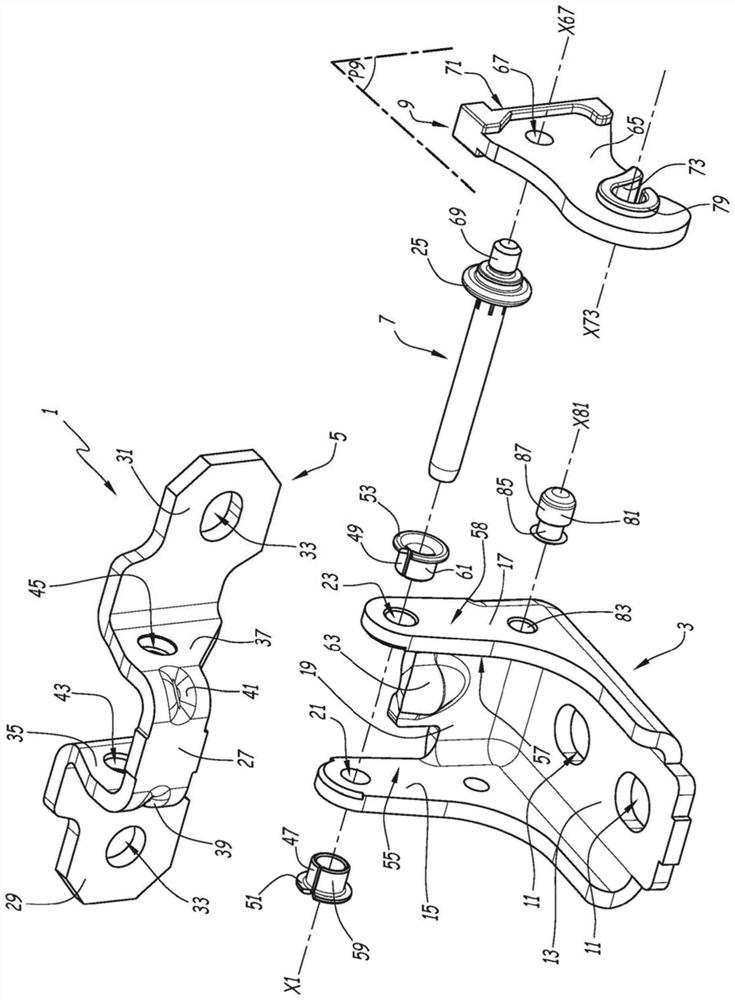

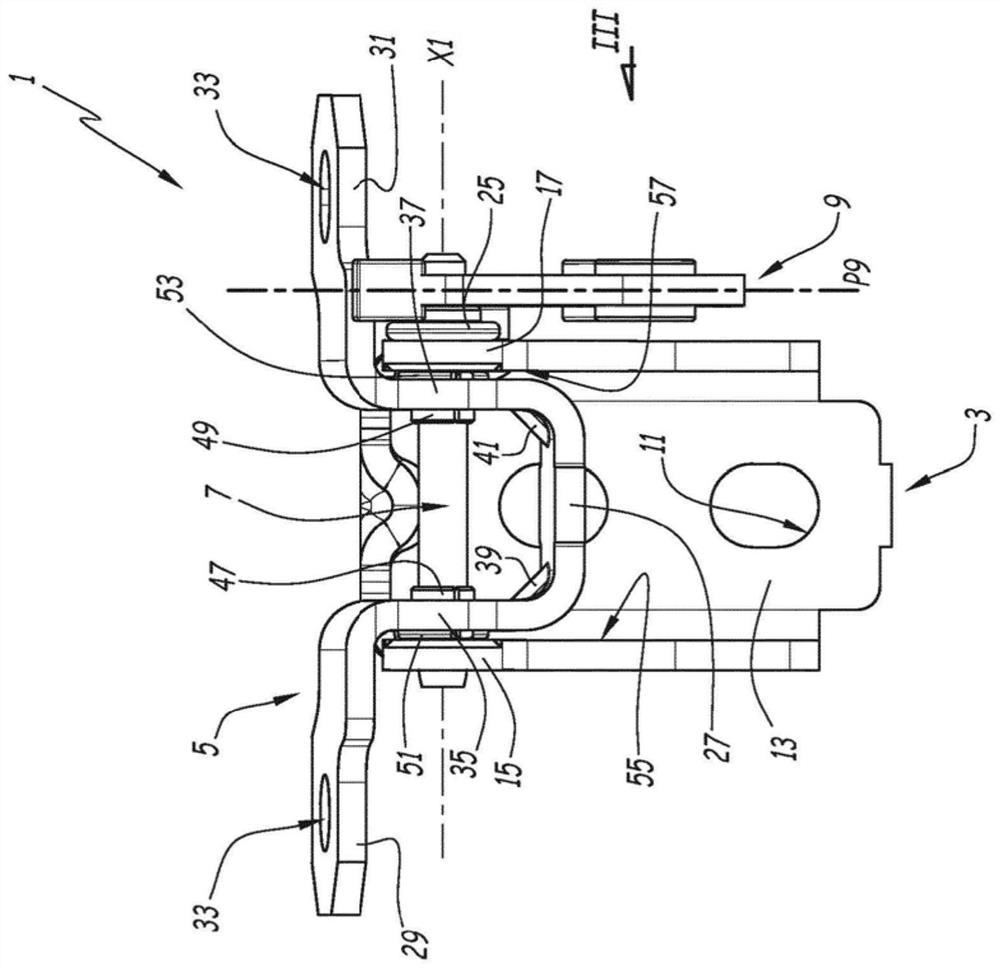

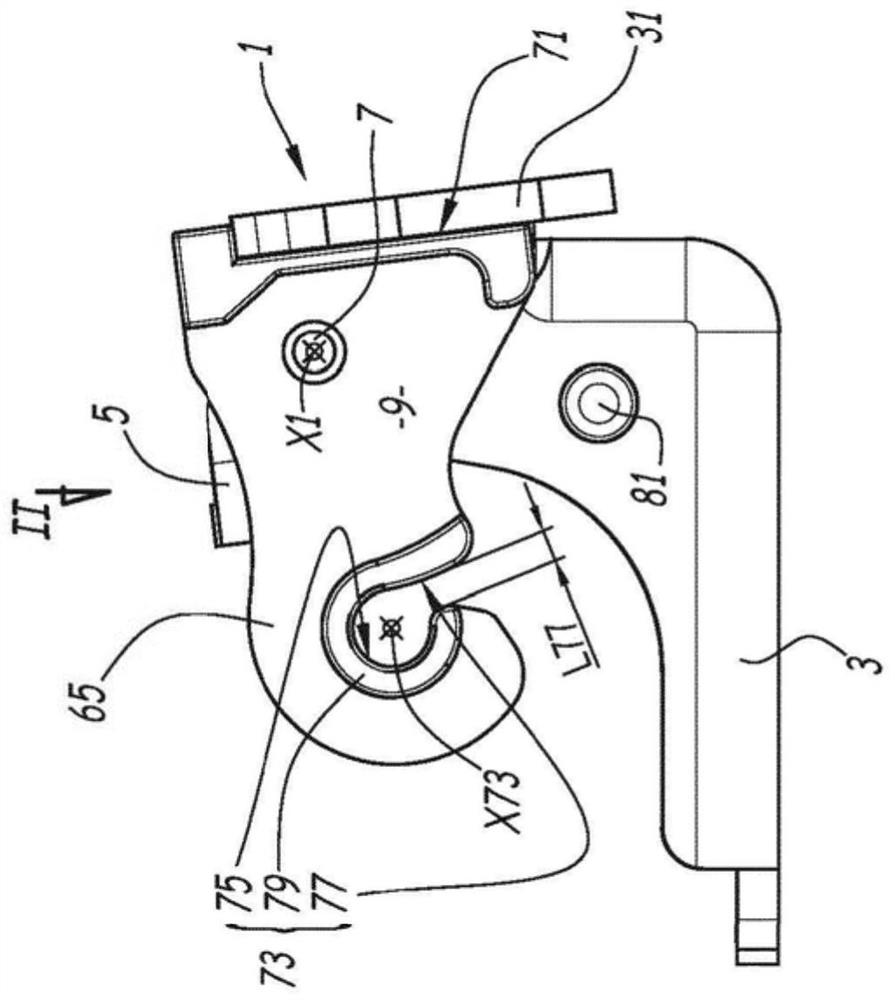

[0043] Figure 1 to Figure 4 The hinge shown is generally designated with reference number 1 . The hinge 1 includes a frame steering knuckle 3 , a leaf steering knuckle 5 , a hinge pin 7 and a buckle device 9 . The leaf steering knuckle 5 corresponds to the first steering knuckle, and the frame steering knuckle 3 corresponds to the second steering knuckle.

[0044] The hinge 1 is designed to equip a motor vehicle, eg a car or a utility vehicle. The hinge 1 is still suitable for equipping other types of vehicles, as long as these vehicles are equipped with at least one revolving door. The hinge 1 constitutes the connecting element to the body for a vehicle swing door, of the passenger or tailgate type.

[0045]In the present case, the frame knuckle 3 is designed to be fixed on the vehicle body via fastening holes 11 provided in the support plate 13 of the frame knuckle 3 . Thus, the frame knuckle 3 constitutes a fixed part relative to the vehicle body.

[0046] The frame k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com