Efficient corrosion-resistant multifunctional washing machine

A multi-functional, cleaning machine technology, applied in the field of cleaning machines, can solve the problems of being easily oxidized by acid-base potions, short service life of relays, and injury to users, and achieve the effects of not being easy to freeze, effectively stabilizing pressure, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

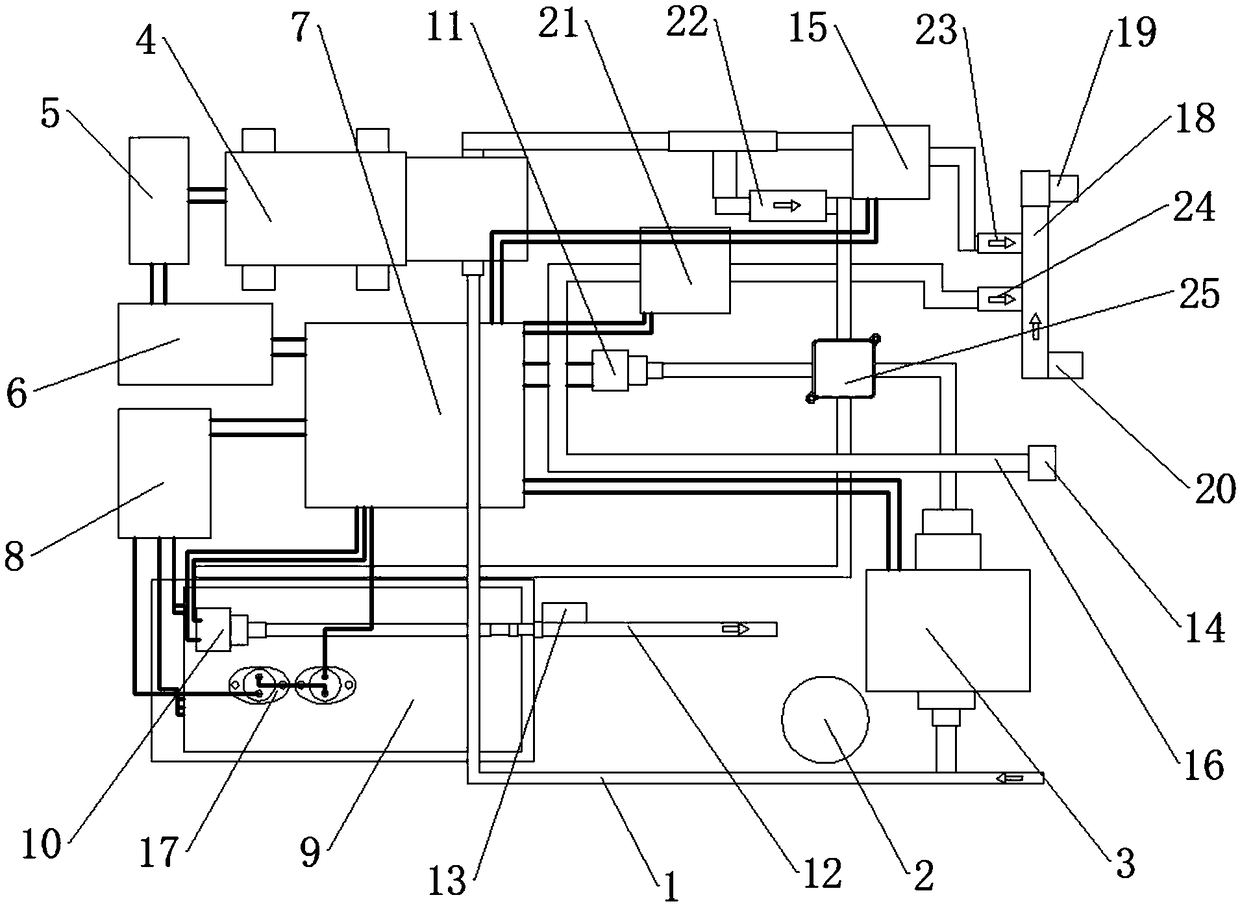

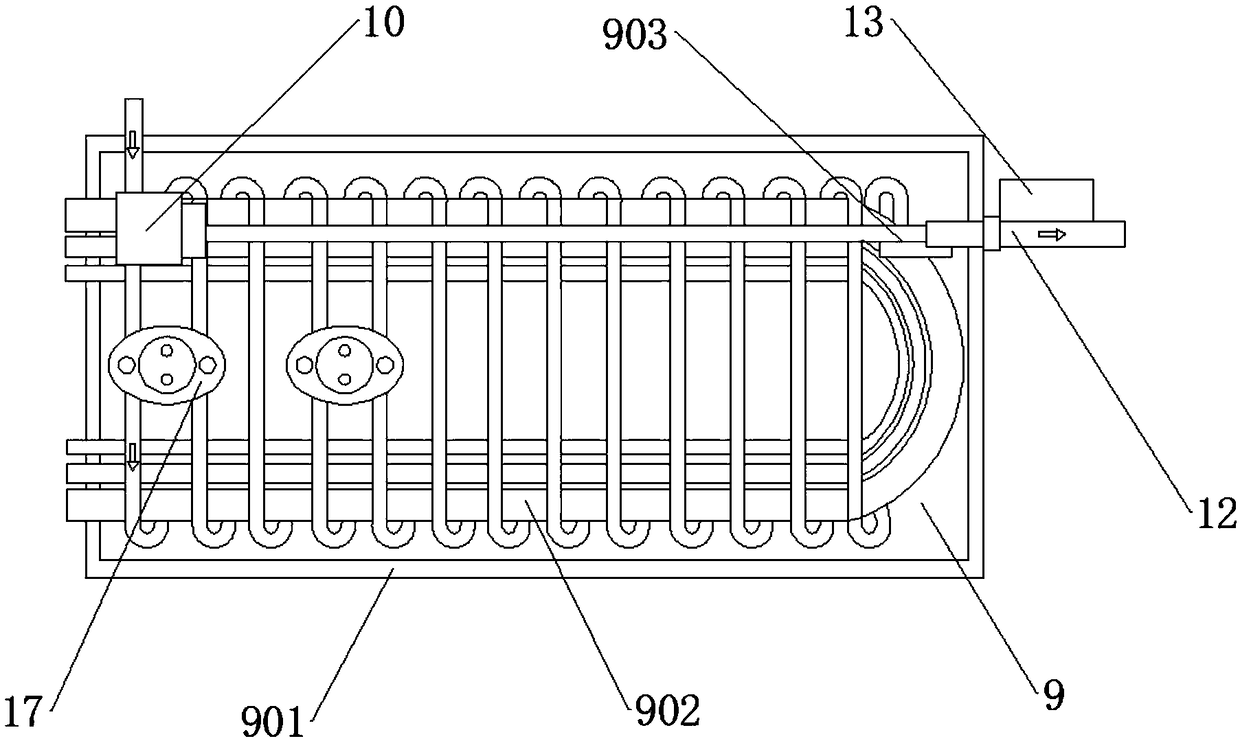

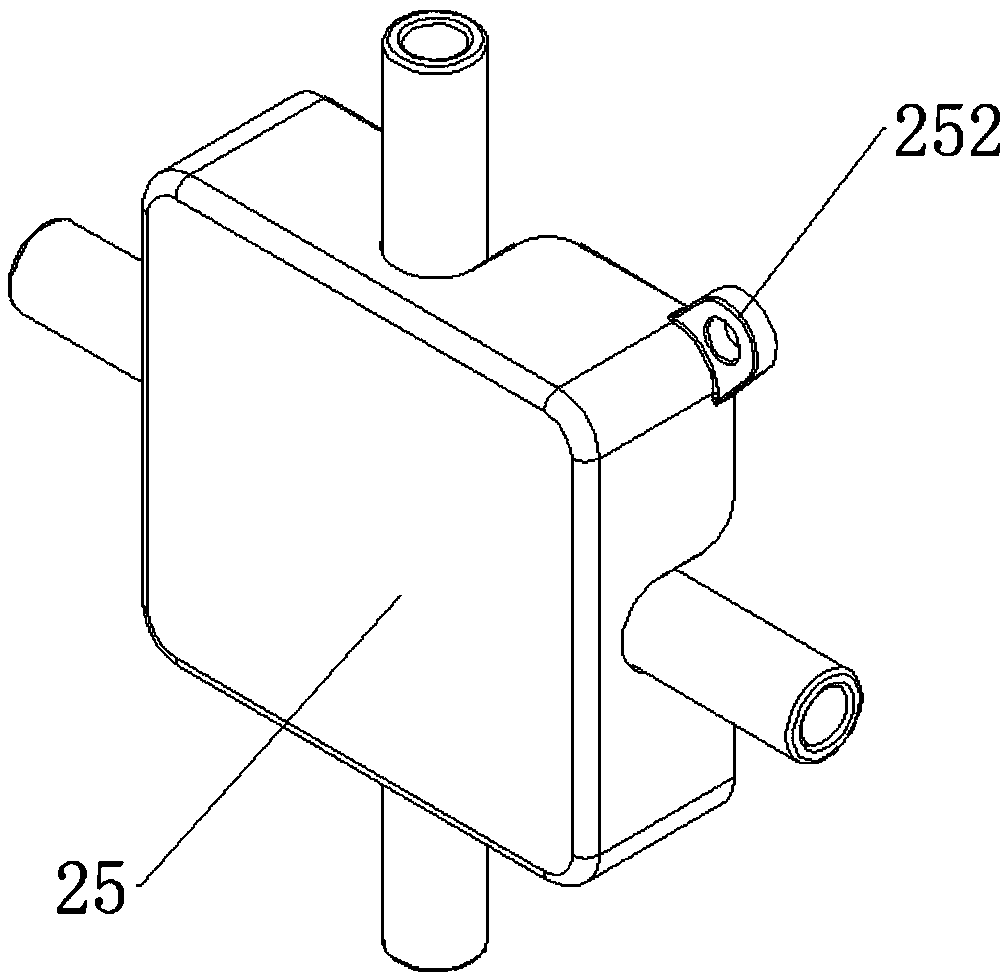

[0041] see figure 1 , a high-efficiency anti-corrosion multifunctional cleaning machine, including a high-pressure water pump 4 installed inside the cleaning machine, a pulse generating tube 18, a control circuit 7, a heating body 9, a second solenoid valve 21 and a water outlet pipe 12, and the water inlet of the high-pressure water pump 4 is fixed. The main water inlet pipe 1 is connected, the small relay 5 and the main water pump power supply 6 are connected in series between the high pressure water pump 4 and the control circuit 7, and the first water pipe is connected between the water outlet end of the high pressure water pump 4 and the pulse generating pipe 18, the first water pipe The first electromagnetic valve 15 and the second one-way valve 23 are fixedly connected to the top in turn, the first electromagnetic valve 15 is electrically connected to the control circuit 7, and the second water pipe is fixedly connected in turn between the water outlet of the high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com