Automatic positioning system structure of truck girder moulding mould

A technology for forming molds and positioning systems, applied in positioning devices, manufacturing tools, vehicle parts, etc., can solve problems such as low production efficiency, difficulty in automatic loading and unloading of beam forming molds, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

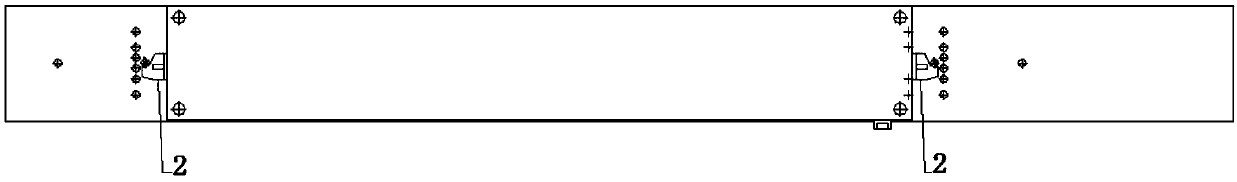

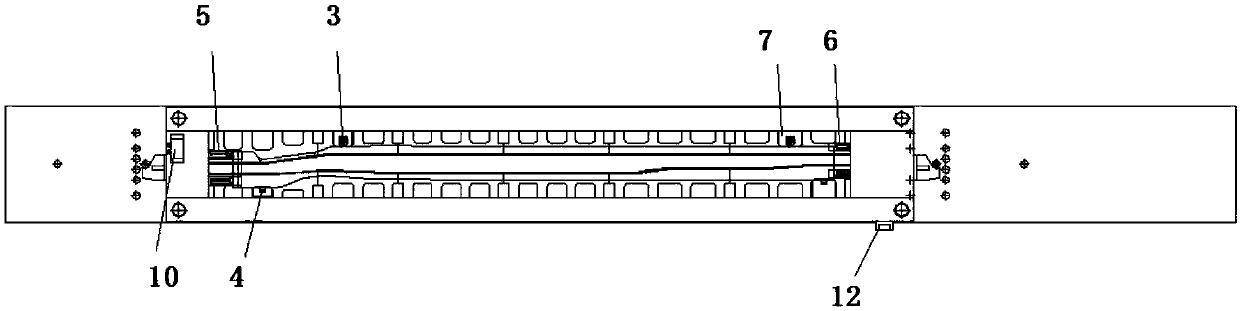

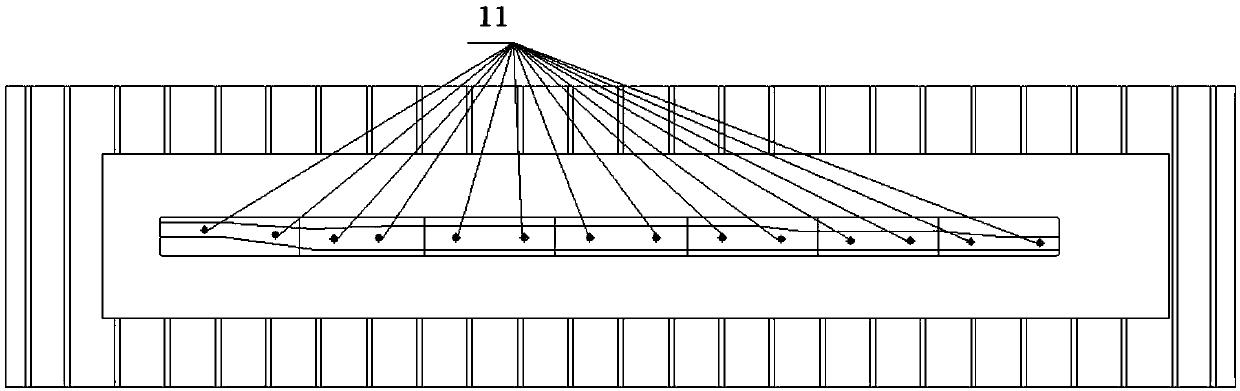

[0028] Such as Figures 1 to 8 As shown, the present invention provides an automatic positioning system structure for truck frame molding dies, which includes: upper and lower molds installed on the mold base, and the mold base is installed on the press workbench, wherein: the upper and lower molds respectively pass through The installation and positioning system on the mold base is positioned and installed with the mold base; the mold base has a non-standard quick locator type block 2 for the mold base, and the press workbench has a Mark the positioning pins of the quick locator type block 2; the inside of the upper die is arranged with an upper die precise guide assembly 11 along the lateral direction of the upper die, and the inside of the lower die is arranged with: precisely guiding the upper die Component 11 is a positioning plate assembly that is positioned and matched and arranged along the transverse direction of the lower die, and the positioning plate assembly has m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com