A 3D printing method

A 3D printing and outer surface technology, applied in the field of 3D printing, can solve problems such as poor economic benefits, increased parts manufacturing costs and processing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the embodiments of the present invention, the specific implementation manners embodying the features and advantages of the embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

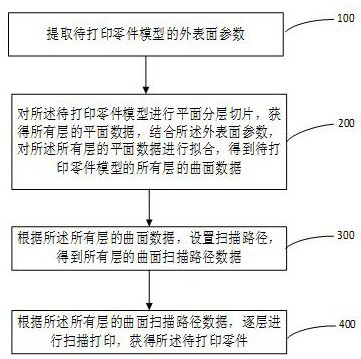

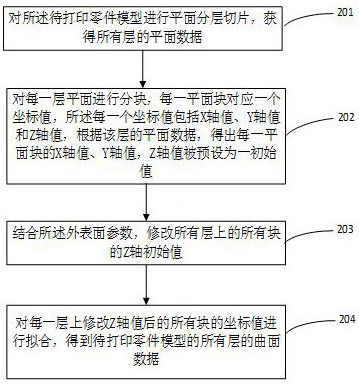

[0017] The embodiment of the present invention discloses a 3D printing method, including:

[0018] 100, extracting the outer surface parameters of the part model to be printed;

[0019] As the part to be printed is a curved surface structure, the outer surface parameters of the part model are extracted. The outer surface parameters include: three-dimensional coordinate values of the outer surface of the part model, that is, the X-axis value, the Y-axis value and the Z-axis value.

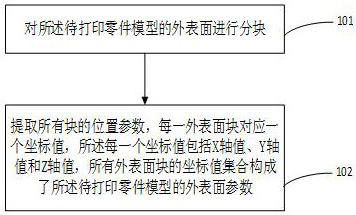

[0020] Specifically, in this embodiment, step 100 includes:

[0021] 101. Divide the outer surface of the part model to be printed into blocks;

[0022] The numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com