Composite material microwave high-pressure curing device

A composite material and curing device technology, which is applied in the field of composite material high-pressure curing equipment and composite material microwave high-pressure curing device, can solve the problems of lack of surface temperature measurement and visual monitoring facilities, and the inability to effectively cool composite materials, so as to simplify the structure complexity , Realize the effect of rapid cooling and efficient automatic door opening and closing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the following examples are only used to illustrate some specific implementation examples of the method, and are not intended to limit the protection scope of the present invention. In addition, after the disclosure of the present invention, any modifications and changes made by those skilled in the art based on the principle of the microwave high-pressure curing molding device for fiber-reinforced resin-based composite materials in the present invention shall fall within the scope of the appended claims of this application scope.

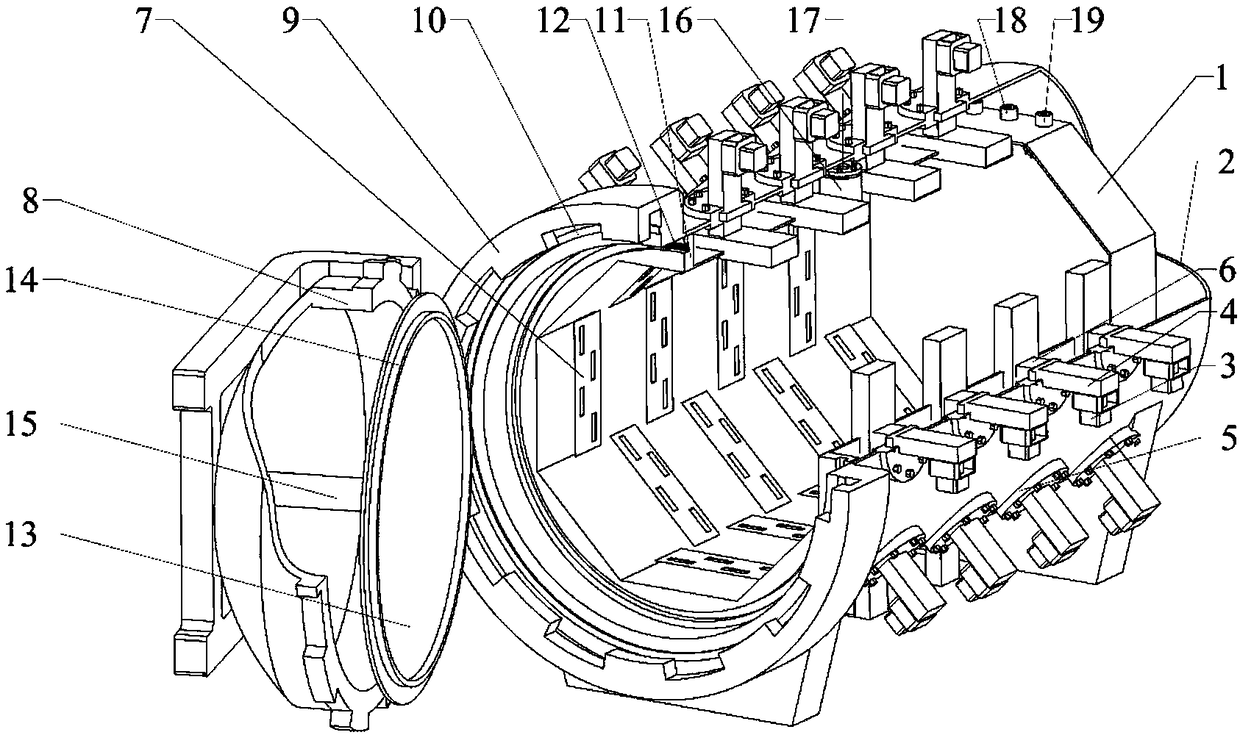

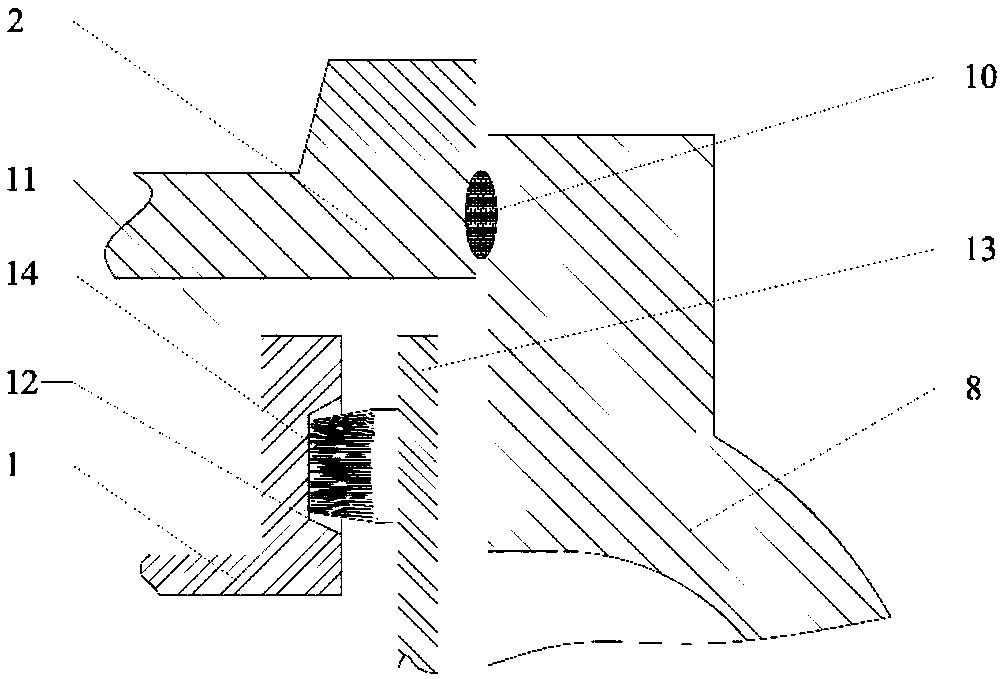

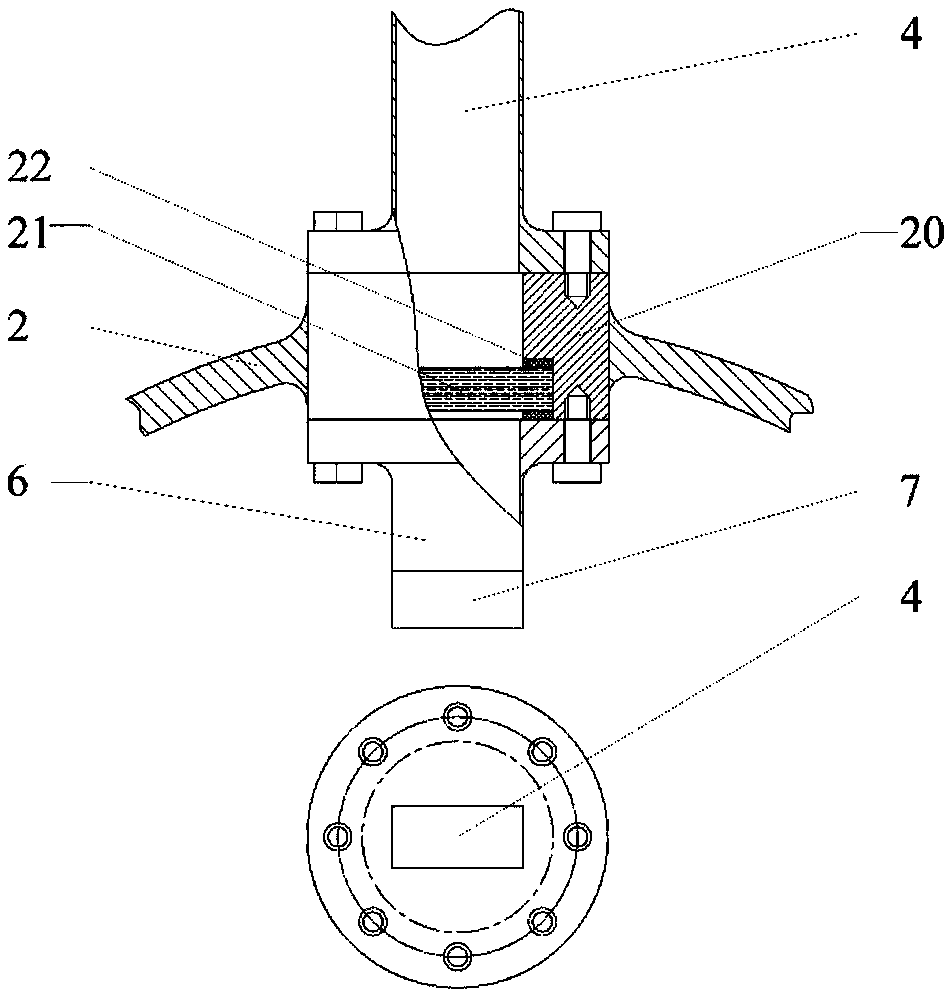

[0031] Such as Figure 1-5 shown.

[0032] A microwave high-pressure curing device for composite materials, which includes an octagonal microwave resonant cavity 1 with a circumscribed circle of 3 meters and a length of 5 meters and a cylindrical high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com