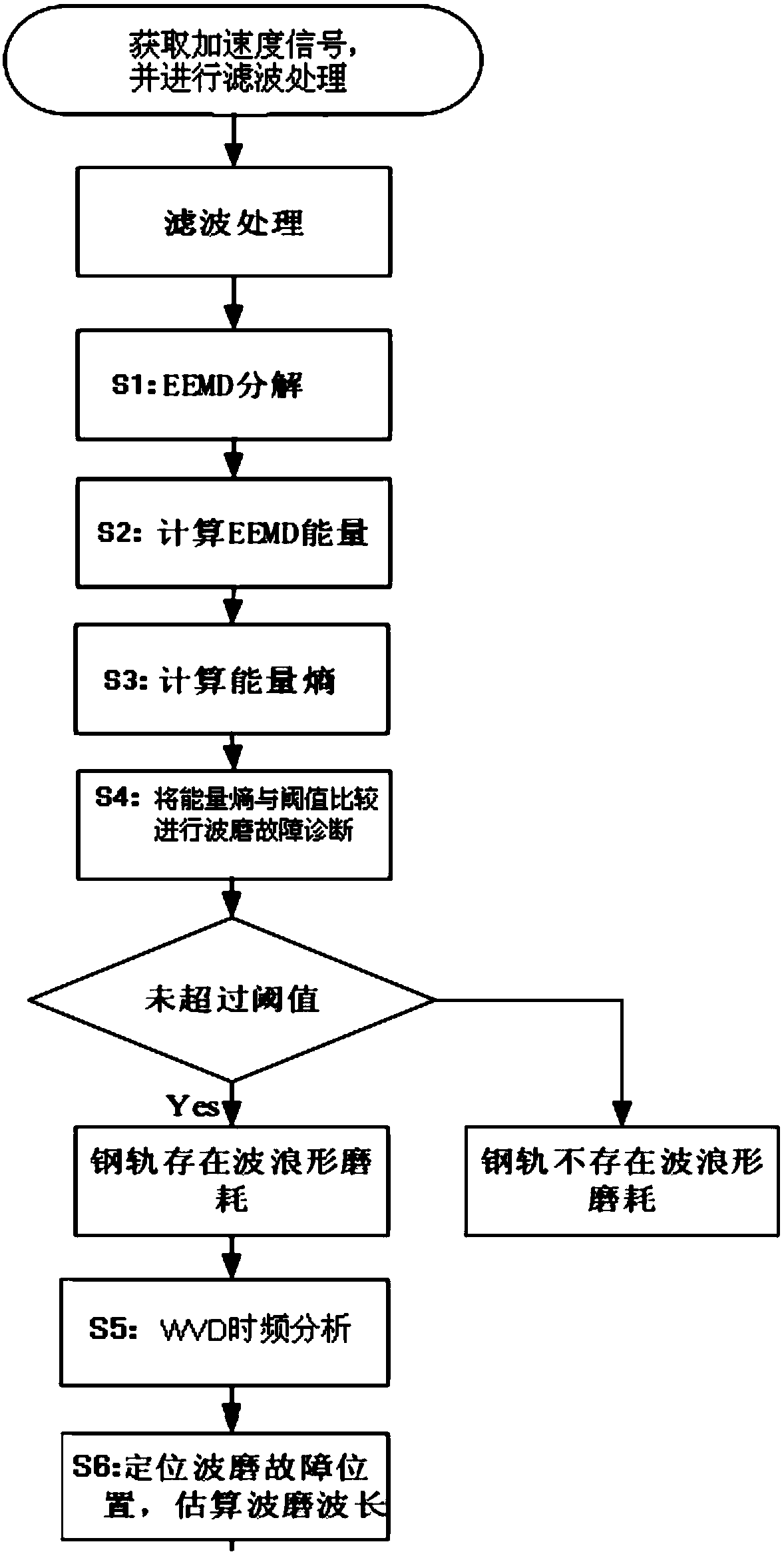

A rail wave mill fault detection method based on EEMD energy entropy and WVD

A technology of fault detection and energy entropy, which is applied in transportation and packaging, character and pattern recognition, pattern recognition in signals, etc., can solve the problems of low detection efficiency and high labor intensity, and achieve simple operation, good real-time performance, and detection high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

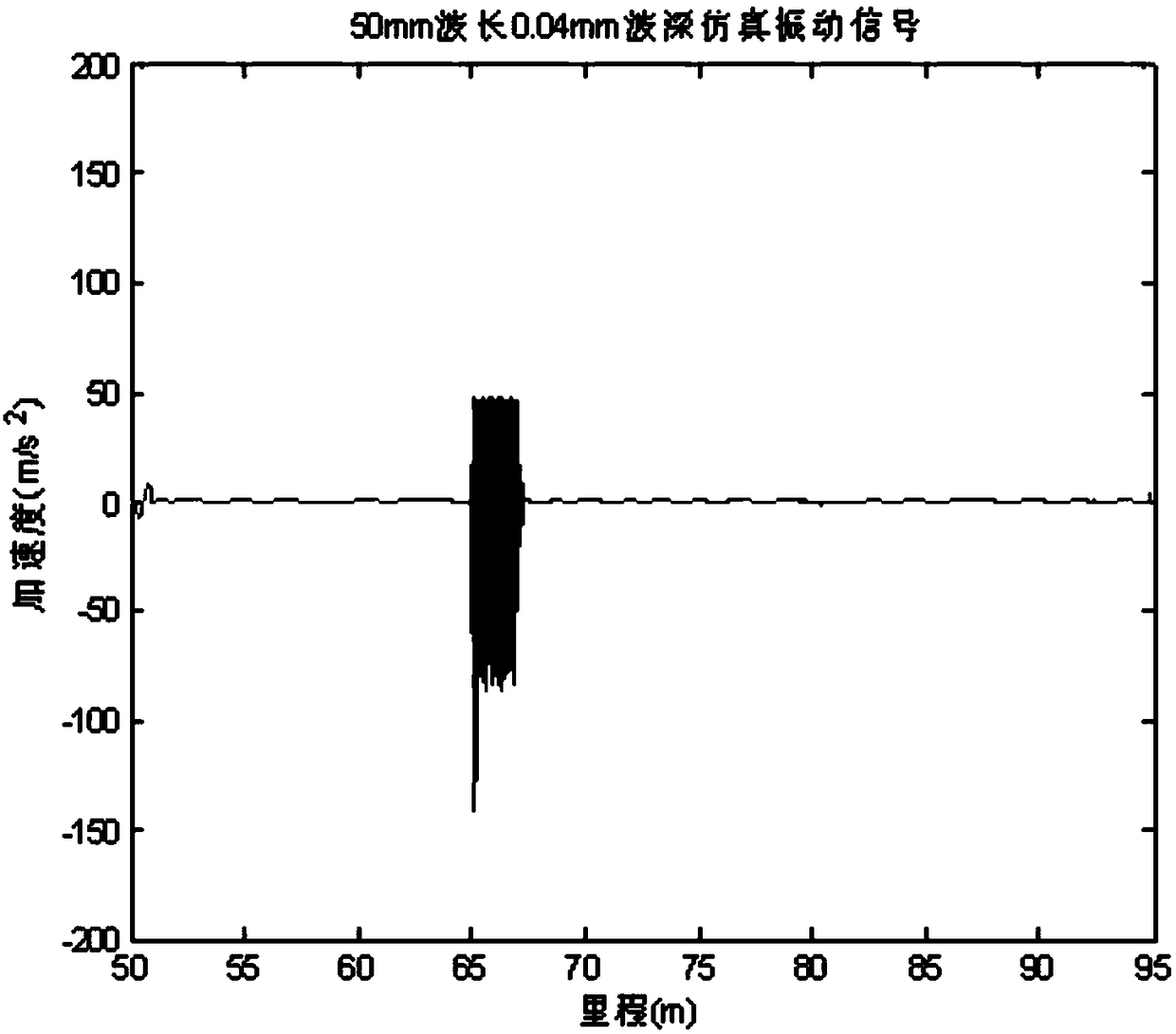

[0102]In this embodiment, in order to simulate the real track state as much as possible, the track setting is carried out by superimposing corrugation on the track spectrum. In the SIMPACK simulation experiment, the sampling frequency is 1kHz, the track length is 95m, and there is only a wave depth of 50mm at 65~-67m. For a track fault of 0.04mm, only the vertical irregularity of the track spectrum exists in other positions. Set the train running speed to 10m / s and other settings, and get as follows figure 2 The vertical vibration acceleration signal of the axlebox is shown.

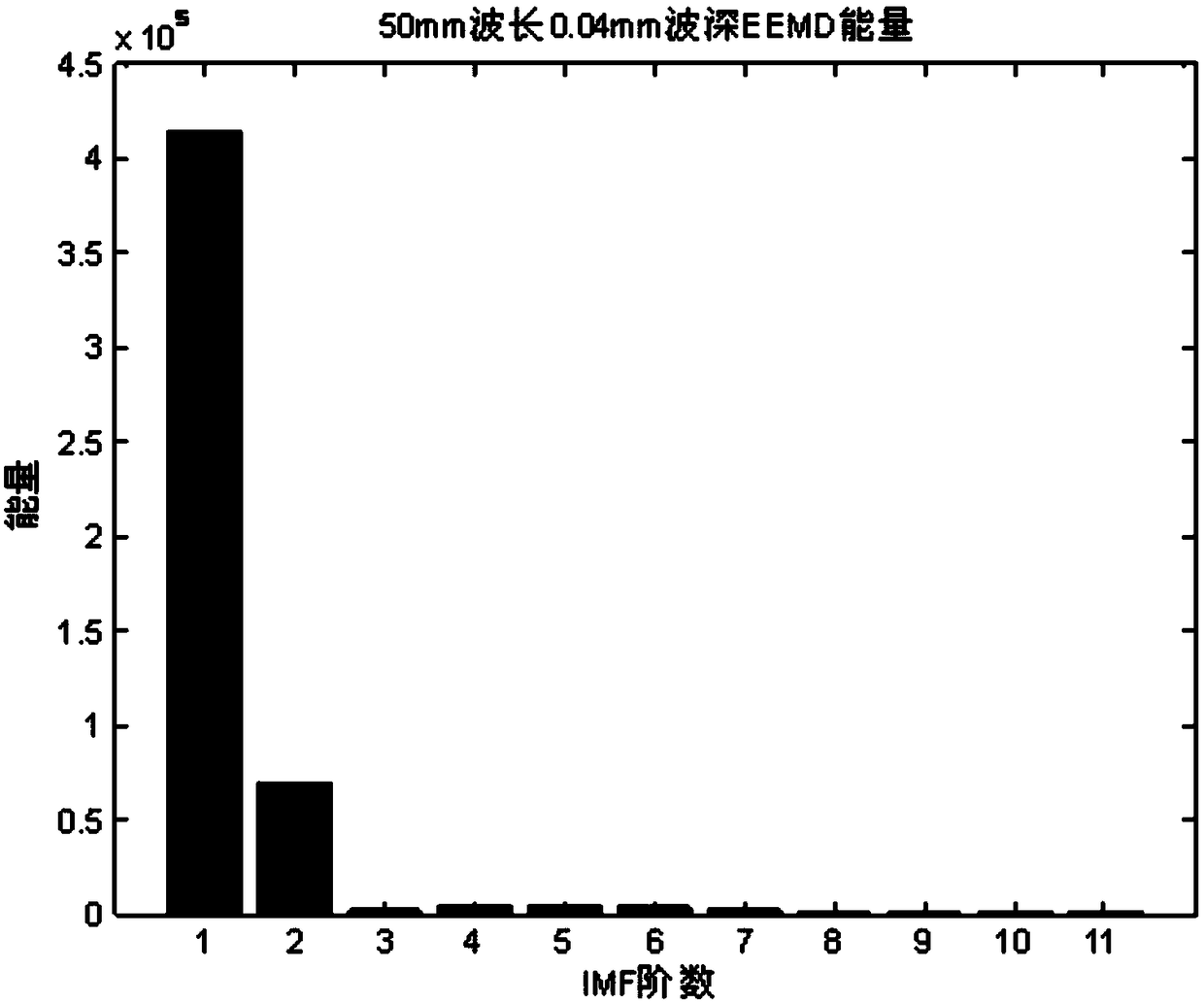

[0103] EEMD decomposition is performed on the collected vibration acceleration signal of the axle box to obtain 11 IMF components and 1 res component. Since the res component is a useless item and has no effect on signal analysis, it is not necessary to process it; the EEMD energy of each IMF component obtained by decomposing is calculated separately, and the following is obtained: image 3 The energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com