An air guide cover for a light truck

The technology of a shroud and truck, which is applied in the field of shrouds, can solve the problems of shroud deformation and low utilization rate, and achieve the effects of better pressure resistance, easy maintenance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

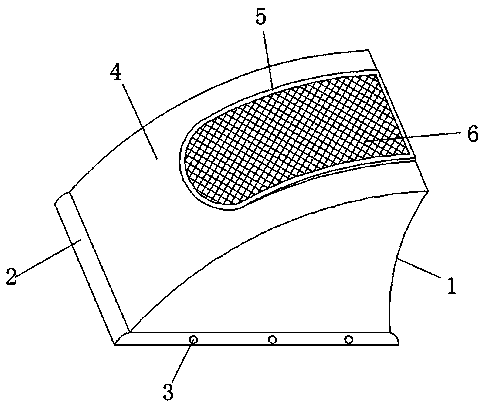

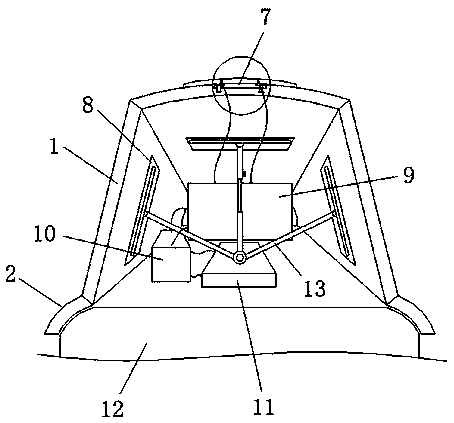

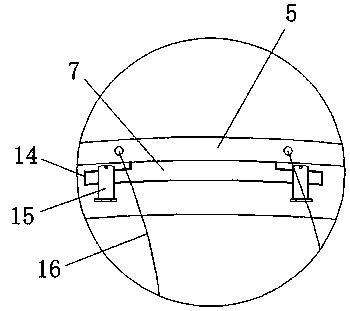

[0022] see Figure 1-4 As shown, a light guide cover for a light truck includes a guide cover body 1 and a truck roof 12. The bottom of the guide cover body 1 is provided with an installation edge 2, and the installation edge 2 is clamped on the top of the truck roof 12. The side 2 is connected with the truck roof 12 through the fixing bolt 3, and the inside of the shroud body 1 is provided with an arc-shaped top plate 4, and the top of the arc-shaped top plate 4 is provided with a mounting groove 14, and a convex block 7 is installed inside the mounting groove 14. The top of the type block 7 is welded with a deflector 5, the inside of the deflector 5 is provided with a solar panel 6, and the inside of the deflector body 1 is installed with an inverter 9, a battery 10 and a refrigerator 11, and the refrigerator 11 is installed on the roof of the truck 12, the inner wall of the shroud body 1 is equipped with a support mechanism 13, the support mechanism 13 is composed of two fi...

Embodiment 2

[0024] In addition, refer to Figure 1-4 , different from the above-mentioned embodiment 1, the inner wall of the shroud body 1 is provided with a limit groove 8, the support mechanism 13 is connected with the limit groove 8 through the fitting plate 23, and the limit groove 8 prevents the fitting plate 23 from fitting on the flow guide When the inner wall of the cover body 1 slips, it causes the support mechanism 13 to be fixed unstable. The two first support rods 17 and one second support rod 18 are arranged in a triangle, and the first support rod 17 and the second support rod 18 are arranged in a triangle. The two support rods 18 are rotationally connected by the rotating shaft 19, the second support rod 18 is divided into two sections by the telescopic rod 20, and the outer wall of one section of the second support rod 18 is equipped with an adjustment bolt 21, and the adjustment bolt 21 passes through the second support rod The outer wall of 18 is in contact with telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com