A production process of electroslag remelting

An electroslag remelting and process technology, which is applied in the field of electroslag remelting production process, can solve the problems such as hindering the forging quality and material utilization rate of electroslag ingots, and the weight of the riser end of electroslag ingots is not clear. The effect of delaying solidification time, improving end quality, forging quality and material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

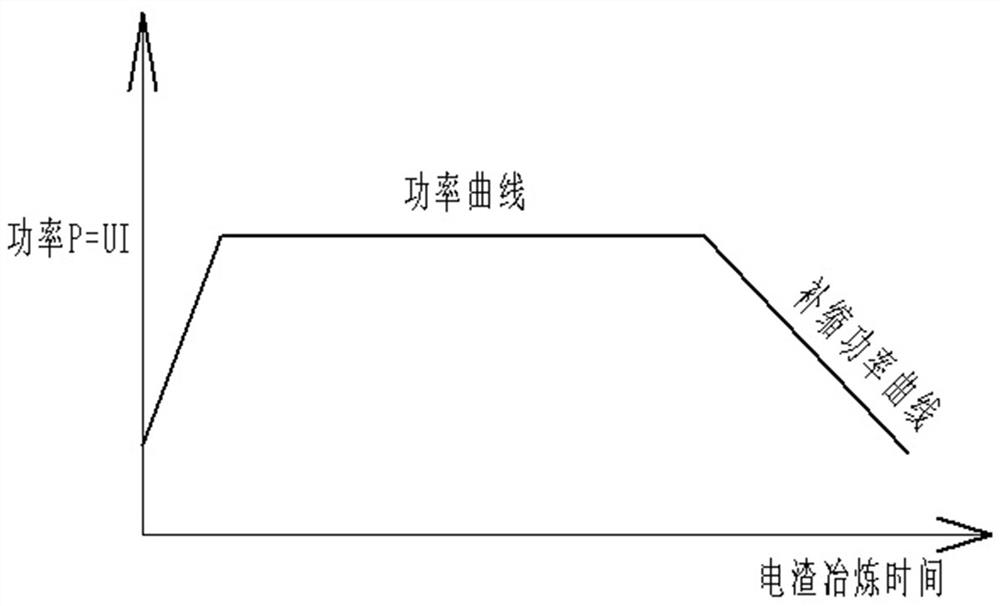

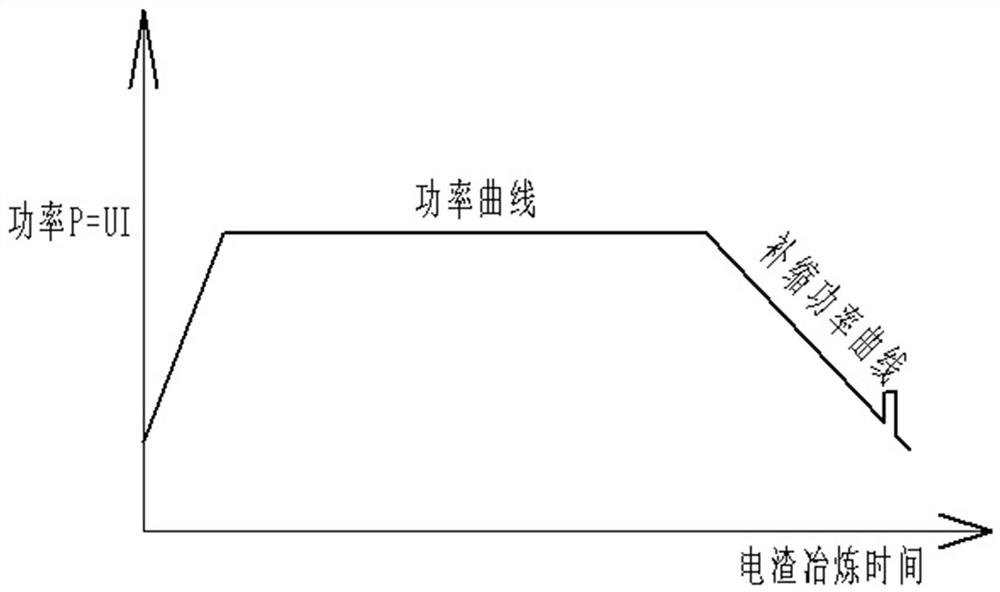

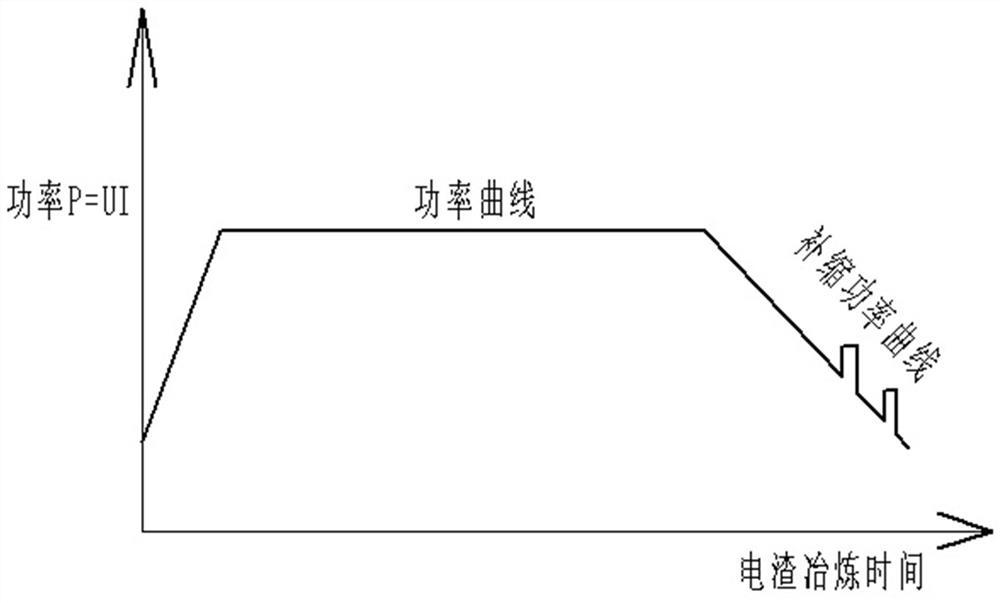

Image

Examples

Embodiment 1

[0019] Embodiment 1: Taking the production process of 10.5 tons of electroslag ingots of a certain product as an example, the specific implementation of the electroslag remelting process of the present invention is as follows:

[0020] (1) The voltage and current process parameters of the original remelting process are shown in Table 1 below:

[0021] Table 1

[0022]

[0023] (2) The voltage and current parameters of the electroslag remelting process of the present invention are shown in Table 2 below

[0024] Table 2

[0025]

[0026] (3) The feeder feeding effect comparison of the original process parameters and the process parameters of the present invention after the implementation is shown in Table 3

[0027] table 3

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com