Die-sleeve type ring rolling forming process for externally square and internally circular forged piece

A technology of circular and mold sleeves, which is applied in the field of forging, can solve the problems of slow wall thickness reduction of forgings, low work efficiency, uneven rotation of forgings and molds, etc. The effect of high forging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the following, the embodiment of the die sleeve type cerclage forming process of the outer square inner circular forging of the present invention will be further described in conjunction with the above-mentioned examples of drawings.

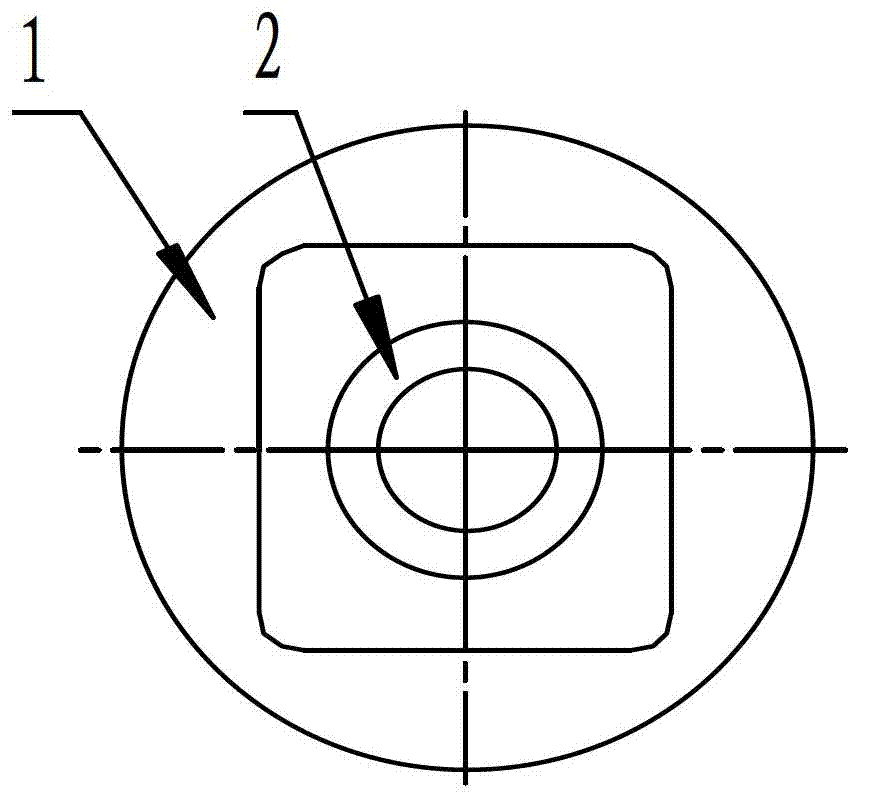

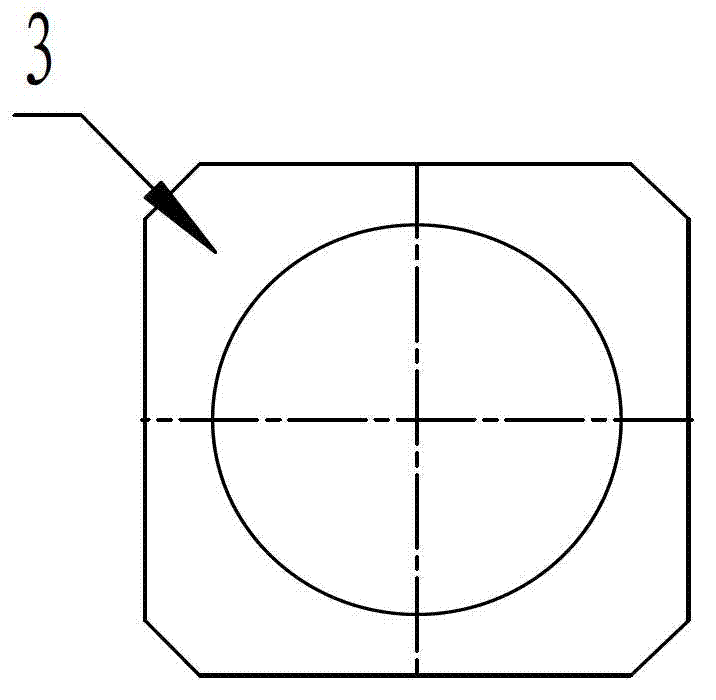

[0013] An example of the cerclage forming process of the outer square inner circle forging of the present invention includes an outer circle inner square mold 1 , a mold cover 2 , and outer square inner circle parts 3 .

[0014] The die sleeve type cerclage forming process of the outer square inner circle forging of the present invention firstly heats the bar to 1150-1180°C, and forges the outer circle inner circle blank through the processes of upsetting, punching and hole expansion, and then Place it in a furnace at 1150-1180°C for heating.

[0015] Preheat the outer circle inner square mold 1 and the mold cover 2 at 300-400°C, put the preheated mold cover 2 on the core roller of the CNC ring rolling machine, and then place the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com