Steam temperature characteristic optimal adjusting method for pulverized coal combustion direct current furnace

A technology of pulverized coal combustion and adjustment method, which is applied in the direction of controlling combustion, lighting and heating equipment, which can solve problems such as unsatisfactory effect and large deviation of steam temperature, so as to improve the level of economical and efficient operation, reduce loss and alleviate partial burning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

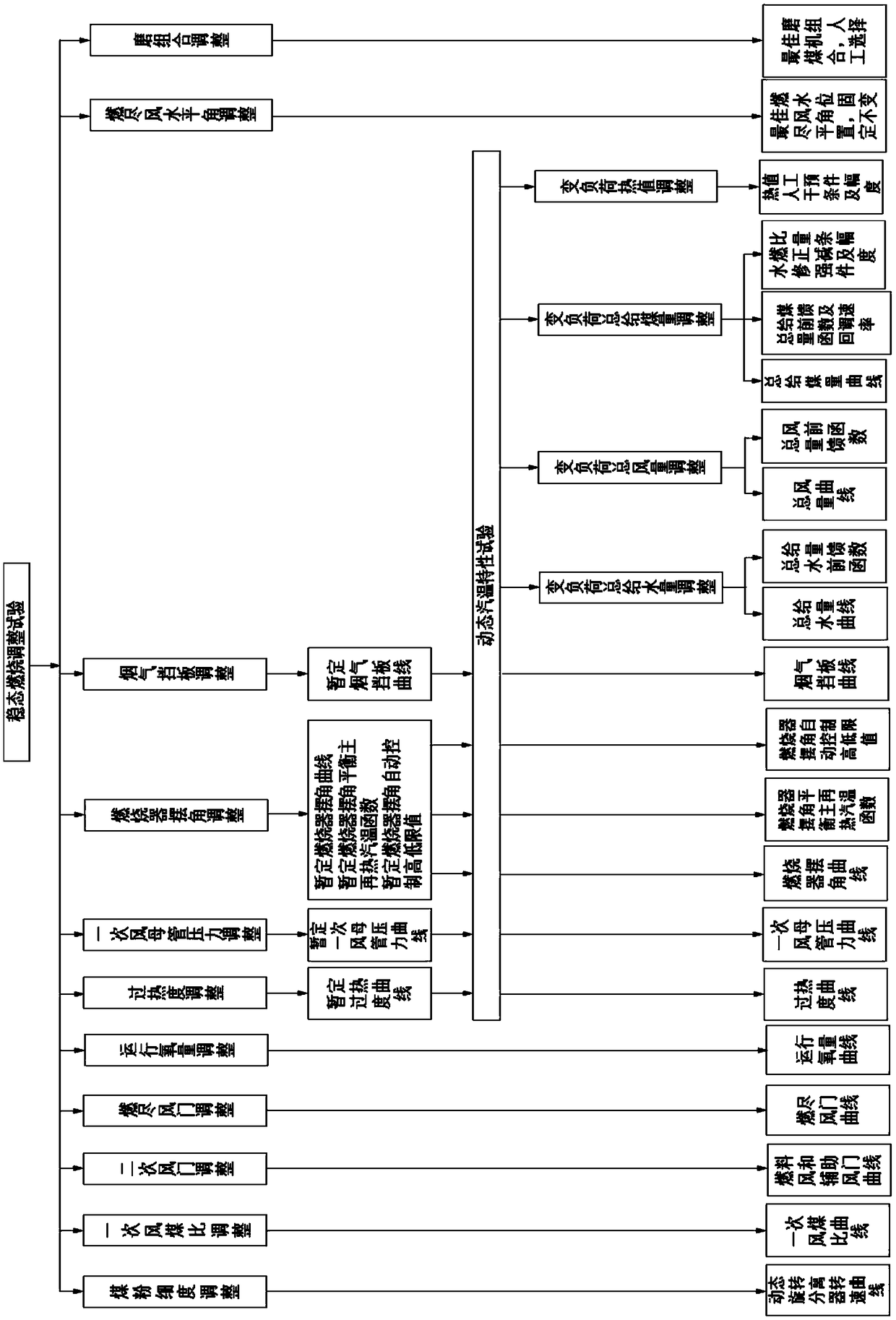

[0035] see figure 1 The flow chart of the method for optimizing and adjusting steam temperature characteristics is shown as an example of optimizing and adjusting the steam temperature characteristics of a front-to-back wall opposed combustion furnace to illustrate the method for optimizing and adjusting steam temperature characteristics of the present invention.

[0036] The method for optimizing and adjusting the steam temperature characteristics of the pulverized coal combustion once-through furnace of the present embodiment 1 comprises the following steps:

[0037] Step S1: Implement various test steps of the steady-state combustion adjustment test;

[0038] Step S2: Implement various test steps of the dynamic steam temperature characteristic test, wherein the dynamic steam temperature characteristic test of some items is based on the corresponding results obtained in the steady state combustion adjustment test in the step S1;

[0039]Step S3: The DCS control system of th...

Embodiment 2

[0054] see figure 1 The flow chart of the method for optimizing and adjusting steam temperature characteristics is illustrated by taking a four-corner tangentially circular combustion furnace as an example to illustrate the method for optimizing and adjusting steam temperature characteristics of the present invention.

[0055] The method for optimizing and adjusting the steam temperature characteristics of the pulverized coal combustion once-through furnace in this embodiment 2 is different from the method in embodiment 1: the opposed combustion furnace in embodiment 1 has no burner swing angle, so in the dynamics of step 2 The primary task in the steam temperature characteristic test is to realize the automatic control input of the flue gas baffle, and the automatic control of the flue gas baffle is the main adjustment method for the reheating steam temperature; In the dynamic steam temperature characteristic test of step S2, the primary task is to realize the input of automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com