Optical fiber composite carbon fiber conductor operating temperature stress monitoring system and monitoring method thereof

A carbon fiber wire and optical fiber composite technology, which is applied to measurement devices, uses optical devices to transmit sensing components, and converts sensor output, etc., can solve the problems of inability to monitor and manage, limit the development prospects of carbon fiber composite core wires, etc. The effect of convenience, small investment and simple interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be described in further detail below in conjunction with the accompanying drawings.

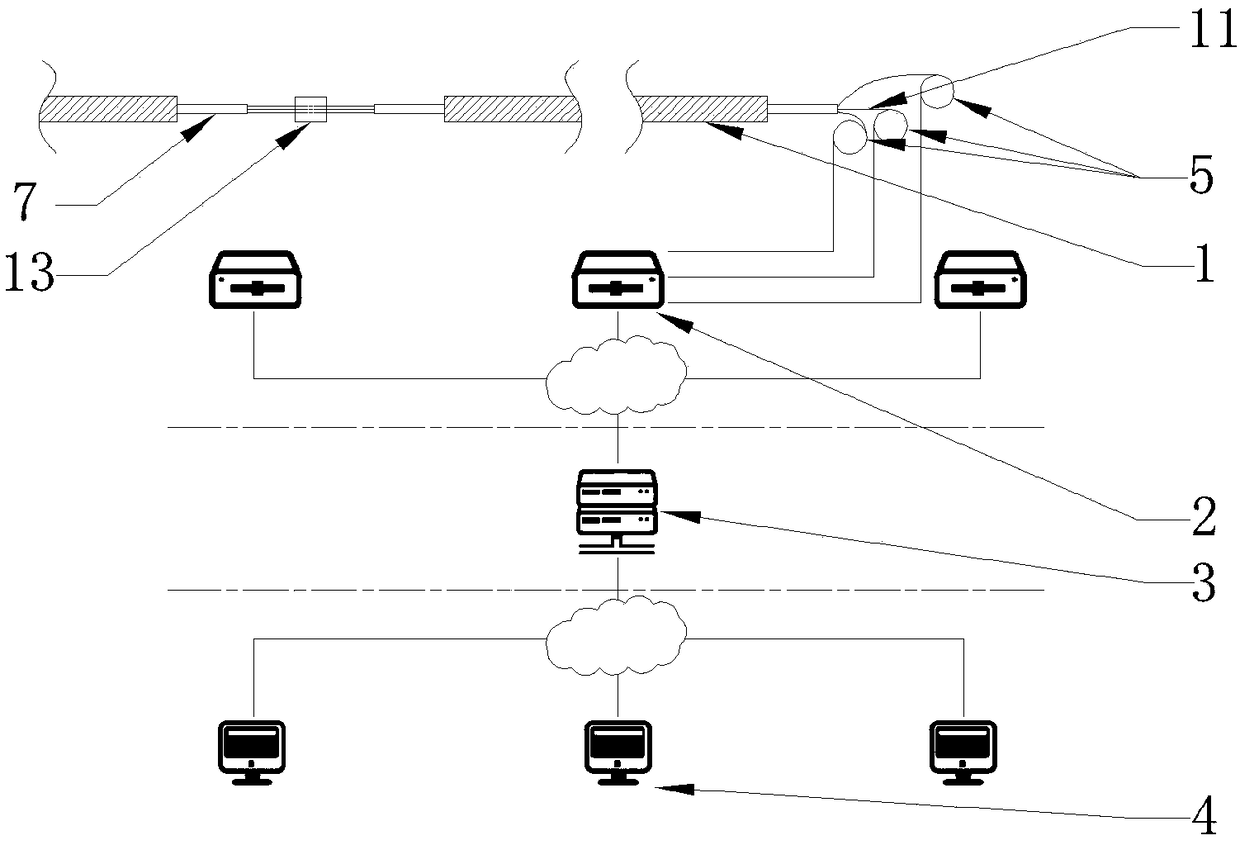

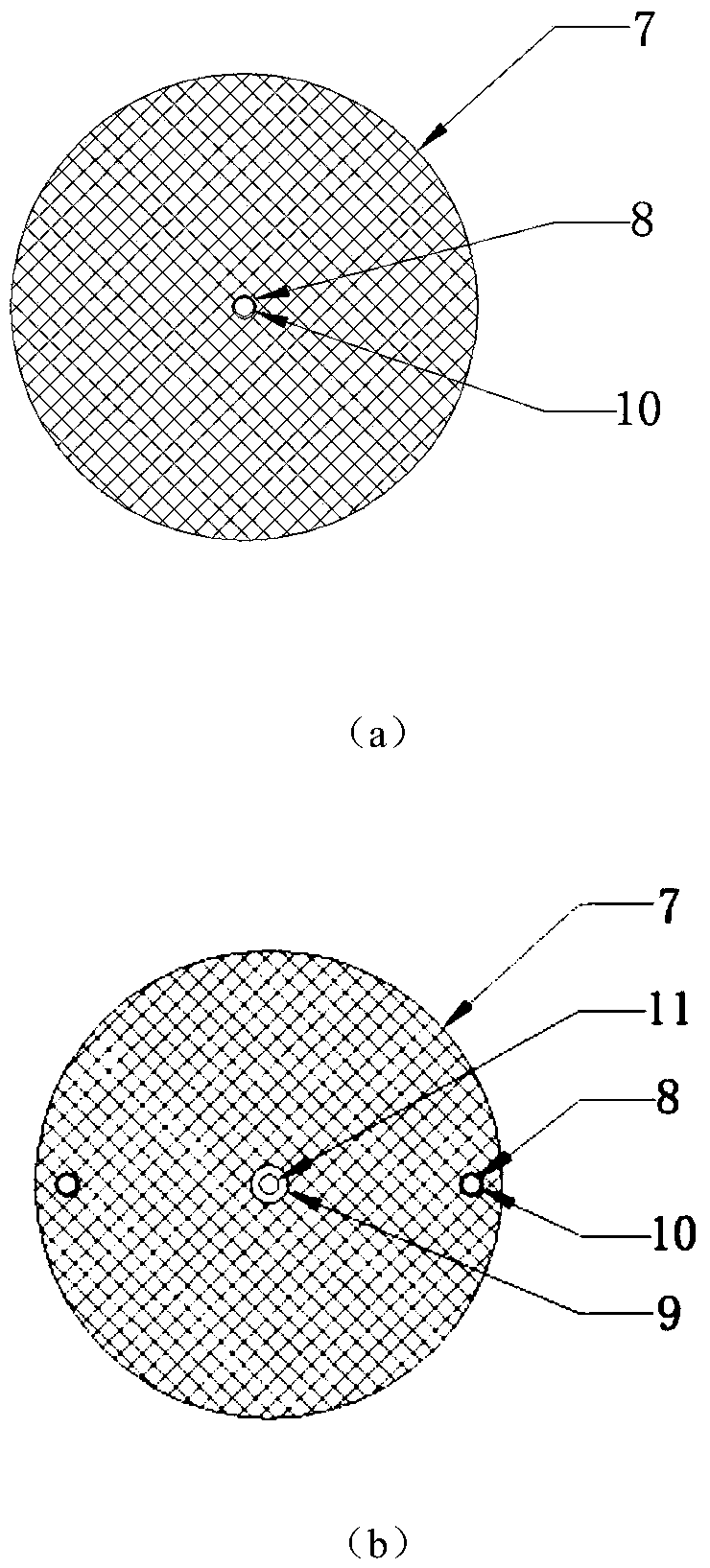

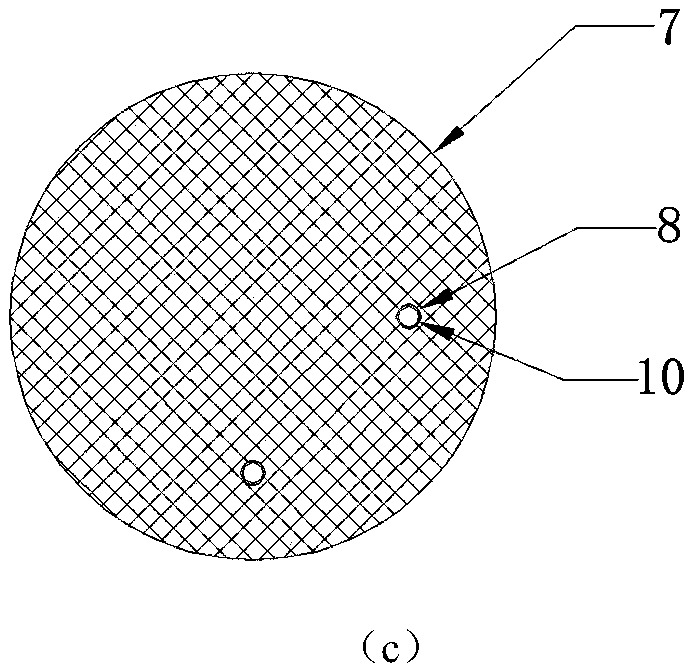

[0024] An optical fiber composite carbon fiber conductor operating temperature stress monitoring system and a monitoring method thereof are based on light scattering principles and material mechanics theories, and are used to provide monitoring information for monitoring clients of power grids. The system includes an optical fiber composite carbon fiber conductor 1, a monitoring front end 2, a monitoring management platform 3, a monitoring client 4, an optical fiber jumper 5, a photoelectric separator 13 and connection accessories. The optical fiber composite carbon fiber conductor 1 is composed of an optical fiber composite carbon fiber core rod 7, a pre-embedded tight-wrapped optical fiber 8 or a pre-buried tight-wrapped optical fiber plus a loose sleeve optical fiber 9 and an outer aluminum single wire. The pre-embedded tight-packed optical fiber 8 contains the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com