Braise sauce composite seasoner and preparation method thereof

The technology of compound seasoning and preparation method, which is applied in the field of food processing, can solve the problems of different tastes of dishes, hinder the development and growth of Chinese food, unstable taste of dishes, etc., and achieve the effects of reducing production costs, alleviating symptoms of anorexia, and mellow smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

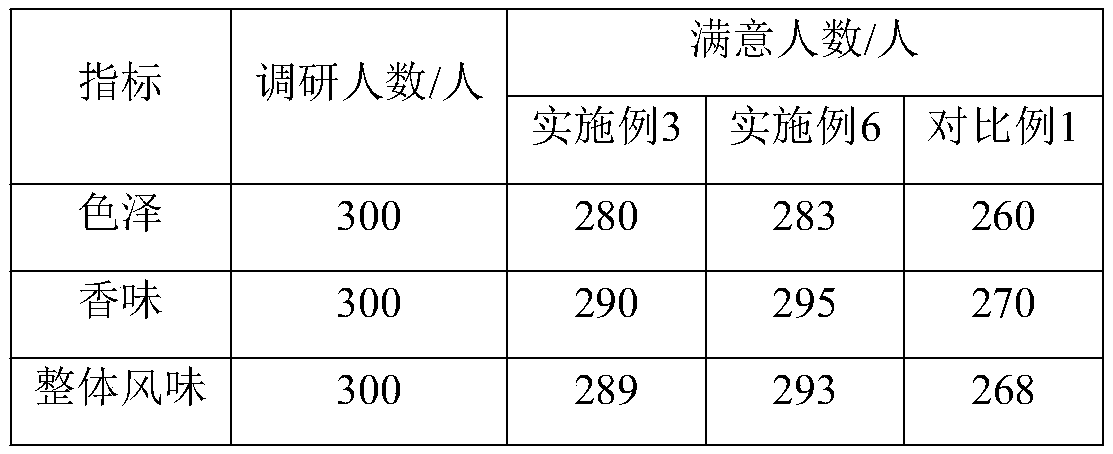

Examples

Embodiment 1

[0036] First, weigh 1.87kg of garlic grains, 1.88kg of ginger grains, 1.89kg of green onion grains, 0.45kg of aniseed ingredients, 3.20kg of tomato paste, 6.5kg of first-grade soybean salad oil, 1.8kg of monosodium glutamate, 1.15kg of salt, and white sugar according to the formula. 4.50kg, 0.45kg cinnamon, 2.40kg dark soy sauce, 3.20kg modified starch, 3.98kg oyster sauce, 81kg purified water for later use; then, use natural gas to heat the pot, pour the first-grade soybean salad oil into the pot and heat to 150°C, add After frying the aniseed ingredients, take them out, add diced green onions, diced ginger, and diced garlic to sauté until fragrant, add oyster sauce and tomato sauce and stir-fry for 1 minute, then add monosodium glutamate, salt, sugar, cinnamon, dark soy sauce, and oyster sauce for frying, and finally Add water and boil for 3 minutes, thicken with modified starch, and prepare the braised sauce compound seasoning.

[0037] If it is necessary to pack and store ...

Embodiment 2

[0039]First, weigh 1.88kg of garlic grains, 1.88kg of ginger grains, 1.90kg of scallion grains, 0.48kg of aniseed ingredients, 3.24kg of tomato paste, 6.8kg of first-grade soybean salad oil, 1.9kg of monosodium glutamate, 1.20kg of salt, and white sugar according to the formula. 4.66kg, 0.48kg cinnamon, 2.42kg dark soy sauce, 3.24kg modified starch, 4.0kg oyster sauce, 81.22kg purified water for standby; then, use natural gas to heat the pot, pour the first-grade soybean salad oil into the pot and heat to 155°C, Add aniseed ingredients and deep-fry until fragrant, then remove, then add scallions, ginger and garlic until fragrant, add oyster sauce and tomato sauce and stir-fry for 1.5 minutes, then add monosodium glutamate, salt, sugar, cinnamon, dark soy sauce, and oyster sauce for frying , and finally add water to boil for 3.5 minutes, thicken with modified starch, and prepare the braised sauce compound seasoning.

[0040] If it is necessary to pack and store the prepared bra...

Embodiment 3

[0042] First, weigh 1.90kg of garlic grains, 1.90kg of ginger grains, 1.90kg of green onion grains, 0.5kg of aniseed ingredients, 3.26kg of tomato paste, 7kg of first-grade soybean salad oil, 2kg of monosodium glutamate, 1.22kg of salt, and 4.88kg of white sugar according to the formula. , 0.5kg of cinnamon, 2.44kg of dark soy sauce, 3.26kg of modified starch, 4.1kg of oyster sauce, and 81.44kg of purified water for use; then, use natural gas to heat the pot, pour the first-grade soybean salad oil into the pot and heat it to 160°C, add large After the ingredients are fried, take them out, add diced green onion, diced ginger and diced garlic to sauté until fragrant, add oyster sauce and tomato sauce and stir-fry for 2 minutes, then add monosodium glutamate, salt, sugar, cinnamon, dark soy sauce, and oyster sauce to fry, and finally add water Cook in a pot for 4 minutes, thicken with modified starch, and prepare the braised sauce compound seasoning.

[0043] If it is necessary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com