A kind of hot rolling forming method of U-shaped steel for bridge support

A hot-rolled forming and section steel technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of easy torsion, waste of manpower, material resources, and high process energy consumption in the finished product, so as to improve rolling stability and avoid Roller winding accident, the effect of flexible selection of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

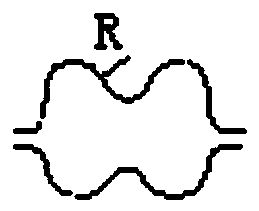

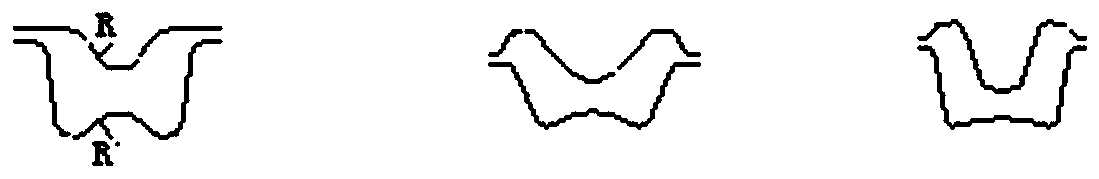

[0035] Refer to attached Figure 1-8 , a method for hot-rolling U-shaped steel for bridge supports, comprising rough rolling, split rolling, finishing rolling and finished rolling;

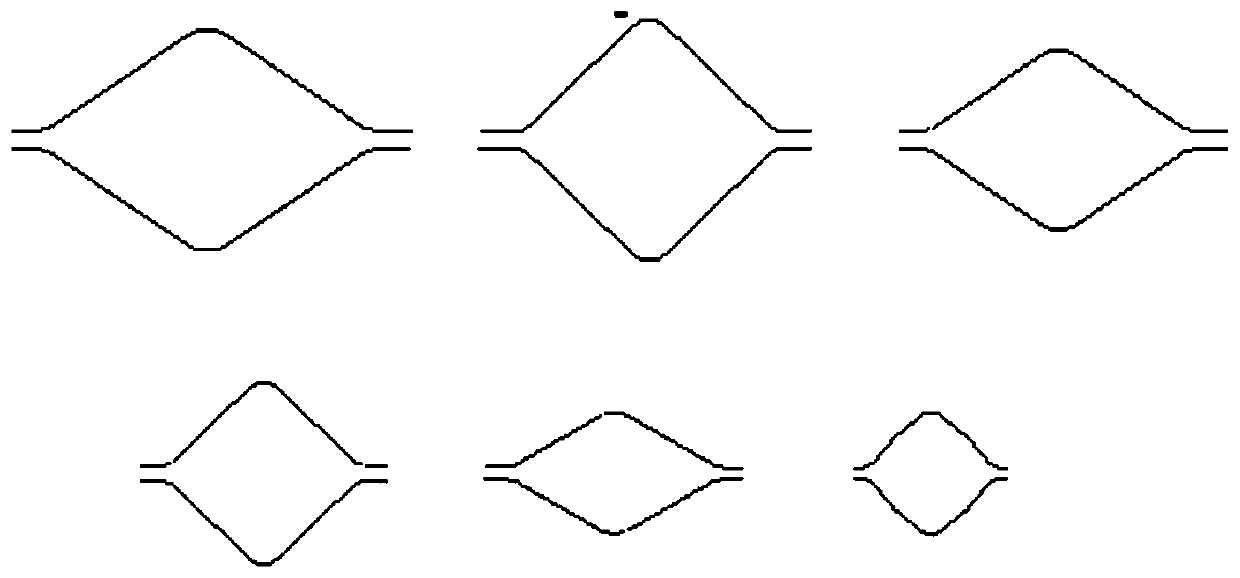

[0036] The rough rolling includes multi-pass rolling, and the rough rolling adopts diamond-shaped and square alternately arranged passes for rolling, the last rough-rolled pass is a square hole, and the four sides of the last rough-rolled square hole are convex arc shape;

[0037] The slitting and rolling is a one-pass rolling, and the slitting and rolling adopts the open pass of the upper and lower two-way cutting, and the last rough-rolled square billet is cut into the middle and connected through the open pass of the upper and lower bidirectional cutting. The two parts of the symmetrical distribution, so that the mass percentage of more than 60% of the metal flows to both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com