Sailboard type stirring mechanism

A mixing mechanism and sail board technology, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problems of uniform sand mixing, uneven mixing, and affecting the production quality of coated sand, etc. , to achieve the effect of cleaning and cleaning materials conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

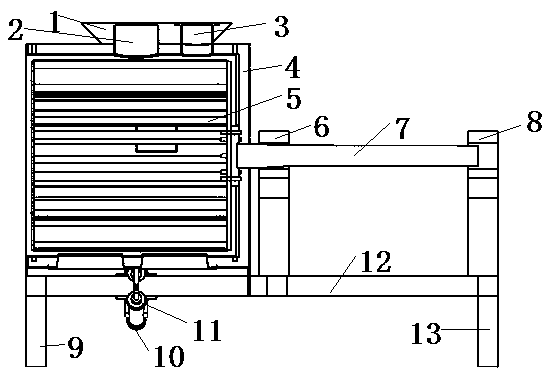

[0012] Aiming at the technical problems existing in the existing sand mixer, the present invention proposes a fan-type mixing mechanism, which includes a sand box, a stirring body, a transmission shaft, and a bracket; Material port, two sand mixing tanks, with a stirring body embedded inside. The stirring body is composed of two end plates connected by sail-type fan blades. The center of the right side of the stirring body is connected with the transmission shaft. The sand box includes the raw sand Feed inlet, two sand mixing tanks, cylinder, and the sand box are in the shape of a horizontal cylinder. The upper end of the outer layer is connected to the raw sand feeding inlet, two sand mixing tanks, and the lower end is a cleaning port that can be opened and closed controlled by the cylinder. In addition, the right end is connected with a transmission shaft, and the left end is a discharge port. The stirring body includes a sail-type fan blade, two boards for fixing the sail-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com