Plate cutting machine and plate cutting method

A cutting machine and plate technology, applied in shearing device, shearing machine equipment, metal processing equipment and other directions, can solve the problems of affecting the quality of the plate, affecting the cutting effect of the plate, laborious plate, etc., to improve the cutting efficiency, reasonable design, Guaranteed cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

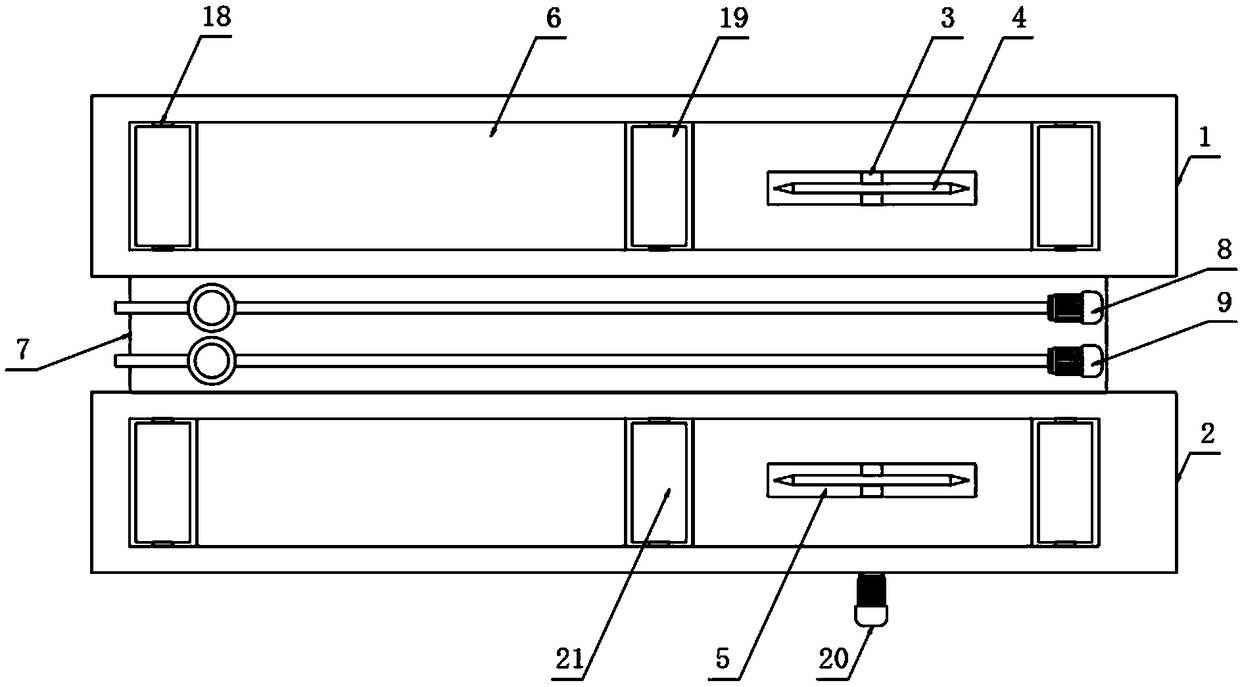

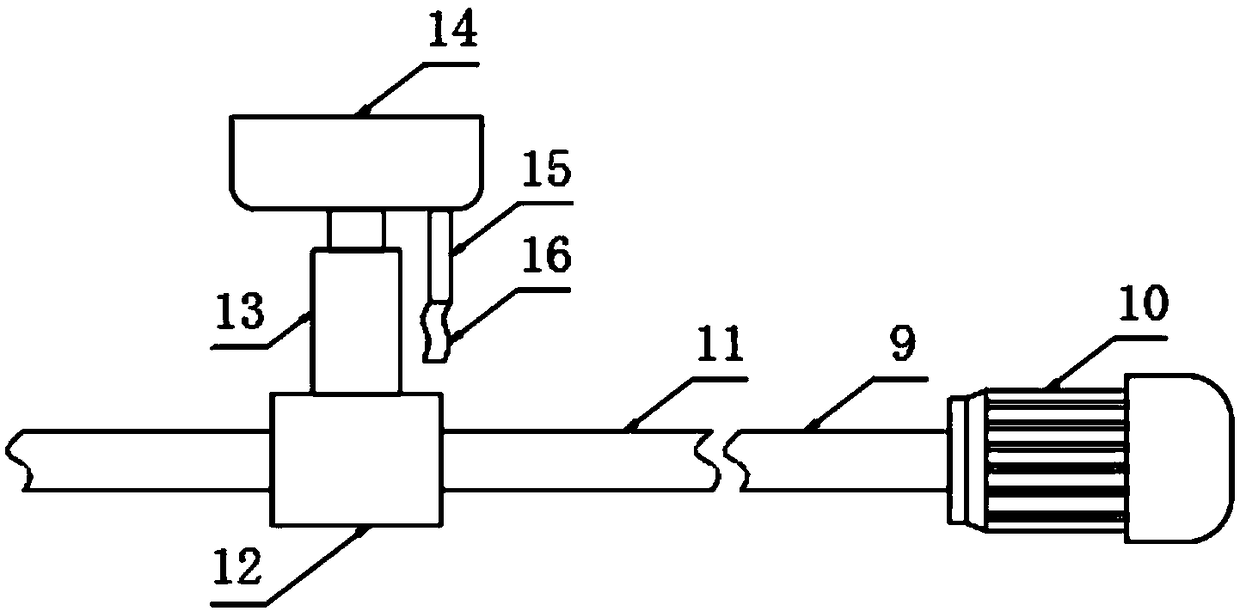

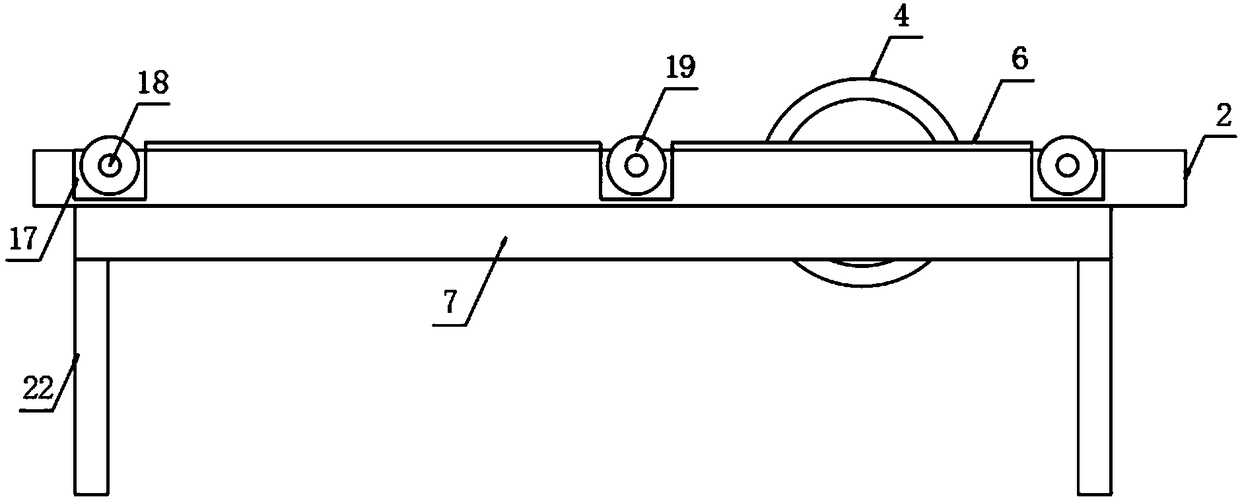

[0024] The present invention provides such Figure 1-3 A kind of plate cutting machine shown, comprises left side cutting platform 1 and right side cutting platform 2, and described right side cutting platform 2 is arranged on the side of left side cutting platform 1, and described left side cutting platform 1 and right side cutting platform The top of the platform 2 is provided with a rubber pad 6 and the bottom is fixedly provided with a bearing base plate 7, and the top of the bearing base plate 7 is provided with a first plate traveling mechanism 8 and a second plate traveling mechanism 9, and the first plate traveling mechanism 8 and the second The plate traveling mechanism 9 includes a first motor 10, the first motor 10 is provided with a screw 11, the outer side of the screw 11 is sleeved with a mounting block 12, and the top of the mounting block 12 is fixed with a cylinder 13, The top of the cylinder 13 is fixed with a rubber suction head 14, the rubber suction head 1...

Embodiment 2

[0035] A plate cutting method, including the plate cutting machine, also includes the following steps:

[0036] S1: Place the plate on the top of the left cutting platform 1 and the right cutting platform 2, so that the end of the plate is in contact with the edge of the cutting tool 4, and after adjusting the position of the plate, use the vacuum pump at the end of the hose 16 to generate suction;

[0037] S2: Then control the extension of the cylinder 13, so that the rubber suction head 14 is adsorbed on the bottom of the plate;

[0038] S3: Then start the first motor 10 and the second motor 20, the first motor 10 drives the second plate traveling mechanism 9 to rotate forward and reverse, so that the mounting block 12 on the second plate traveling mechanism 9 drives the rubber on the top of the cylinder 13 The suction head 14 moves left or right, and the rubber suction head 14 drives the plate to move together;

[0039] S4: When the rubber suction head 14 drives the board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com