Electric cable drum take-up and pay-off system

A cable, retracting and reeling technology, applied in the field of cable reel reeling and reeling system, can solve the problems of high risk, low efficiency, increased work intensity and difficulty, etc., to reduce manpower, improve personal safety, simple and efficient structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

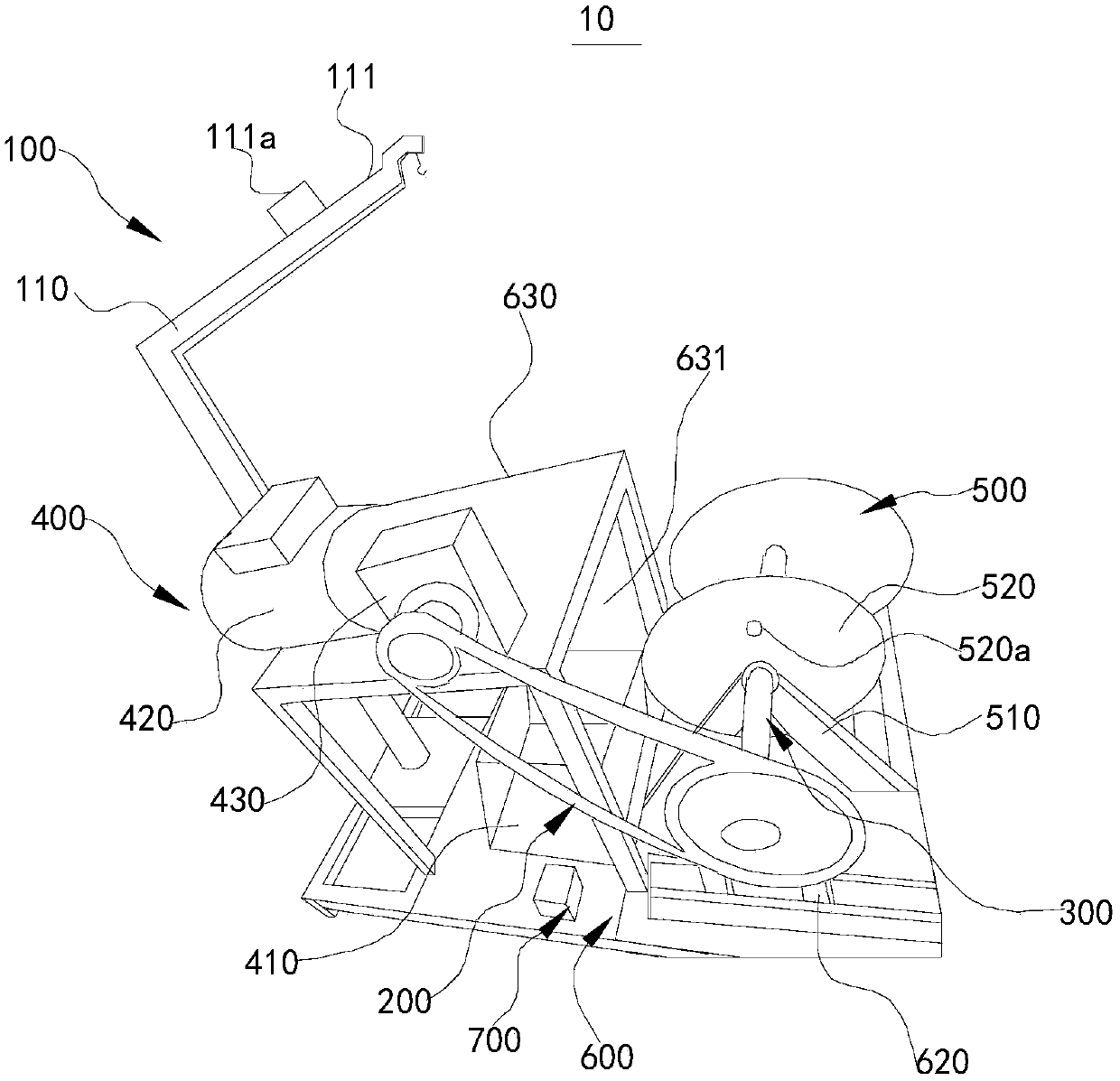

[0080] Please refer to Figure 1 to Figure 8 , Figure 1 to Figure 8 A cable reel take-up and pay-off system 10 is provided.

[0081] The purpose of the present invention is to provide a cable reel take-up and pay-off system 10, which can electrically transfer the cable reel 520 through the reel transfer device 100, by removing the second shaft 320 without disassembling the chain 210 as the transmission group 200 Replace the cable reel 520, replace the cables in a labor-saving, efficient, safe and space-saving way.

[0082] Embodiments of the invention are achieved through the following technical solutions:

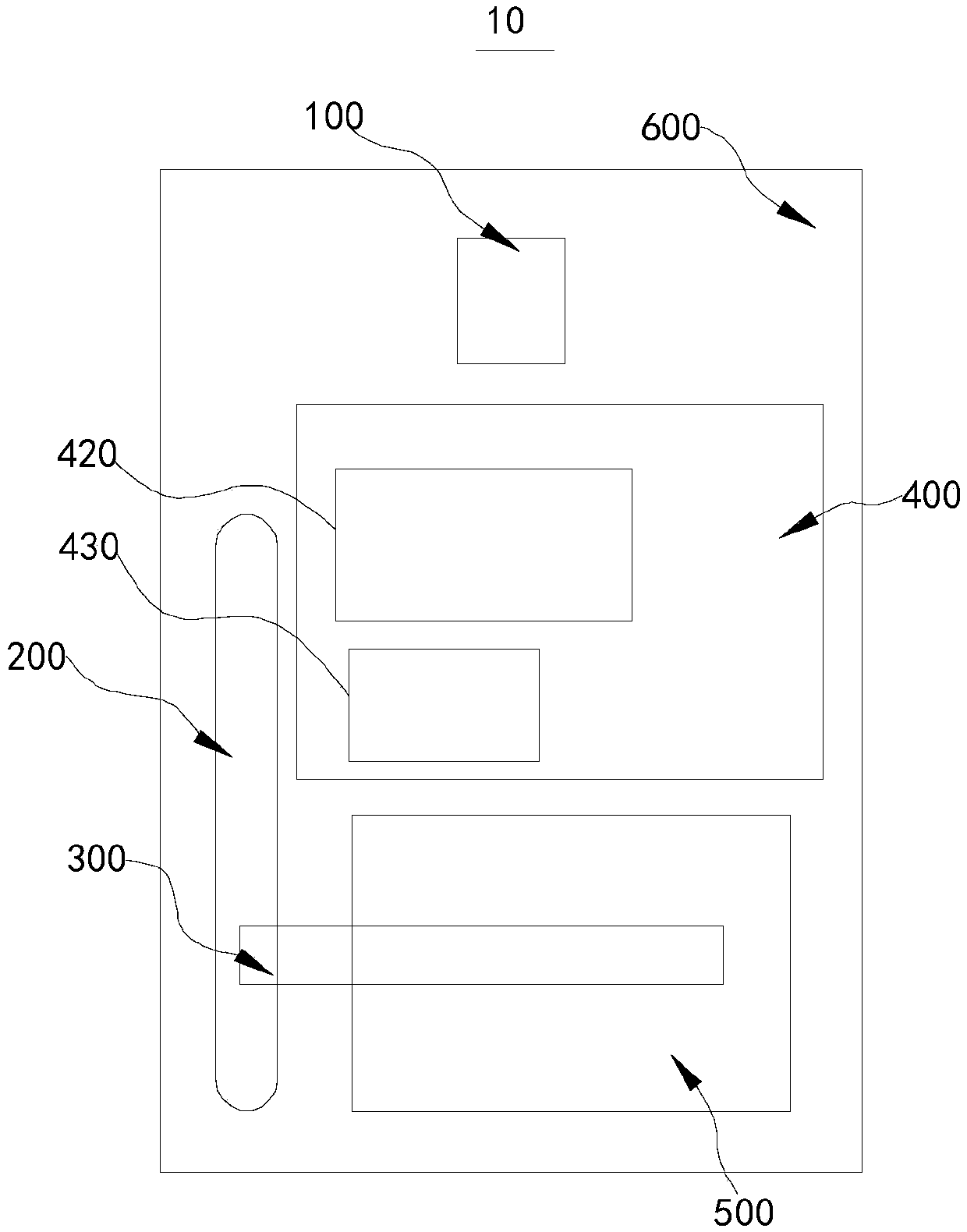

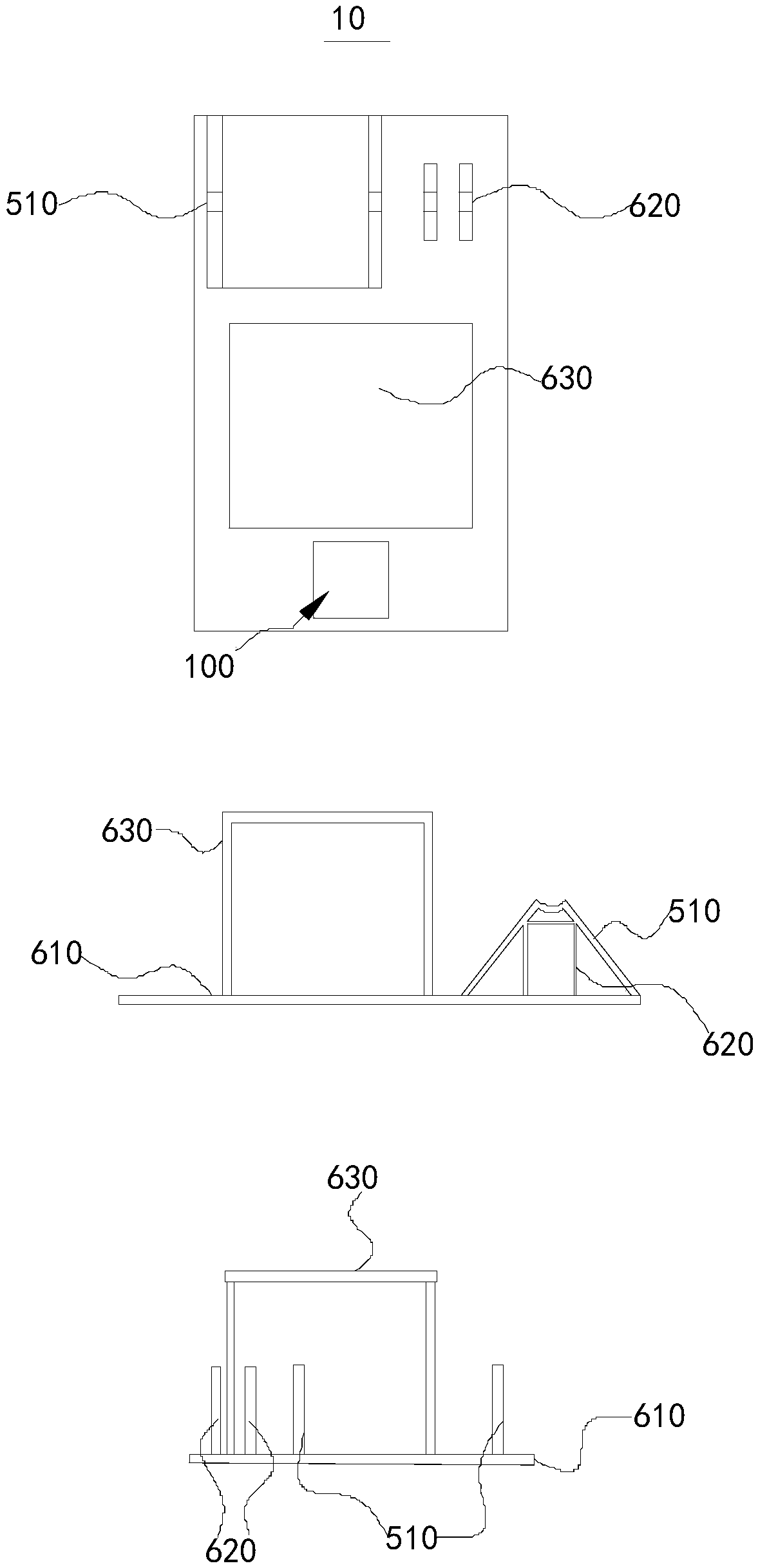

[0083] Please refer to Figure 1 to Figure 3 , a cable reel pay-off system 10, including a reel transfer device 100, a transmission group 200, a biaxial transmission mechanism 300, a power group 400, a work group 500 and a base 600, and the work group 500 includes a cable reel support 510 and The cable reel 520 and the base 600 include a first area 611, a second area ...

Embodiment 2

[0120] Please refer to Figure 1 to Figure 7 ,Please refer to Figure 9 , figure 1 According to this embodiment of the present invention, a cable reel take-up and pay-off system 10 is provided. From figure 1 It can be seen that a cable reel pay-off system 10 includes a reel transfer device 100, a transmission group 200, a biaxial transmission mechanism 300, a power group 400, a work group 500 and a base 600, and the work group 500 includes a cable reel support 510 and cable reel 520, the base 600 includes a first area 611, a second area 612, and a third area 613 in a straight line direction, the working group 500 is arranged in the first area 611, and the power group 400 is arranged in the second area 612, biaxial The transmission mechanism 300 and the reel transfer device 100 are arranged in the third area 613. The double-axis transmission mechanism 300 includes a first shaft 310, a second shaft 320 and a first connecting member 330. The first shaft 310 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com