Dithiosalicylic acid refining device and process

A technology of dithiodibenzoic acid and refining device, applied in organic chemistry and other directions, can solve the problems of reduced production efficiency, mixed impurity powder, dust particles, and content that cannot meet the needs of high-end products, so as to improve work efficiency and improve products. Purity, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

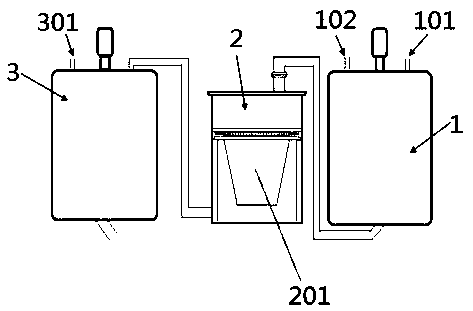

[0029] Add 200kg of dithiodibenzoic acid crude product (wherein the impurity content is about 4%~5%), 1260kg of 30% liquid caustic soda, 1100kg of demineralized water in the dissolution reactor 1, stir and dissolve, and pass the solution into the filter 2, The filtrate flows into the acidification reaction kettle 3 through the pipeline, and 1050 kg of 30% hydrochloric acid is added dropwise. When the pH value of the solution reaches 3.5 and there is no change in the pH within 10 minutes, it is the end of the reaction. The solution is passed into a centrifuge for washing with 1500 kg of water, and dried for 25 minutes. , and dried to obtain 199.8kg of dithiodibenzoic acid refined product, the chromatographic content was 98%, and the yield was 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com