Preparation method of organosilicon mixed rings produced by cracking oil residue with organosilicon

A hybrid ring and organosilicon technology, applied in the direction of silicon organic compounds, can solve the problems of low specific gravity, no open heating method, high energy consumption, and achieve stable equipment operation, convenient cleaning and maintenance, and stable and safe equipment operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

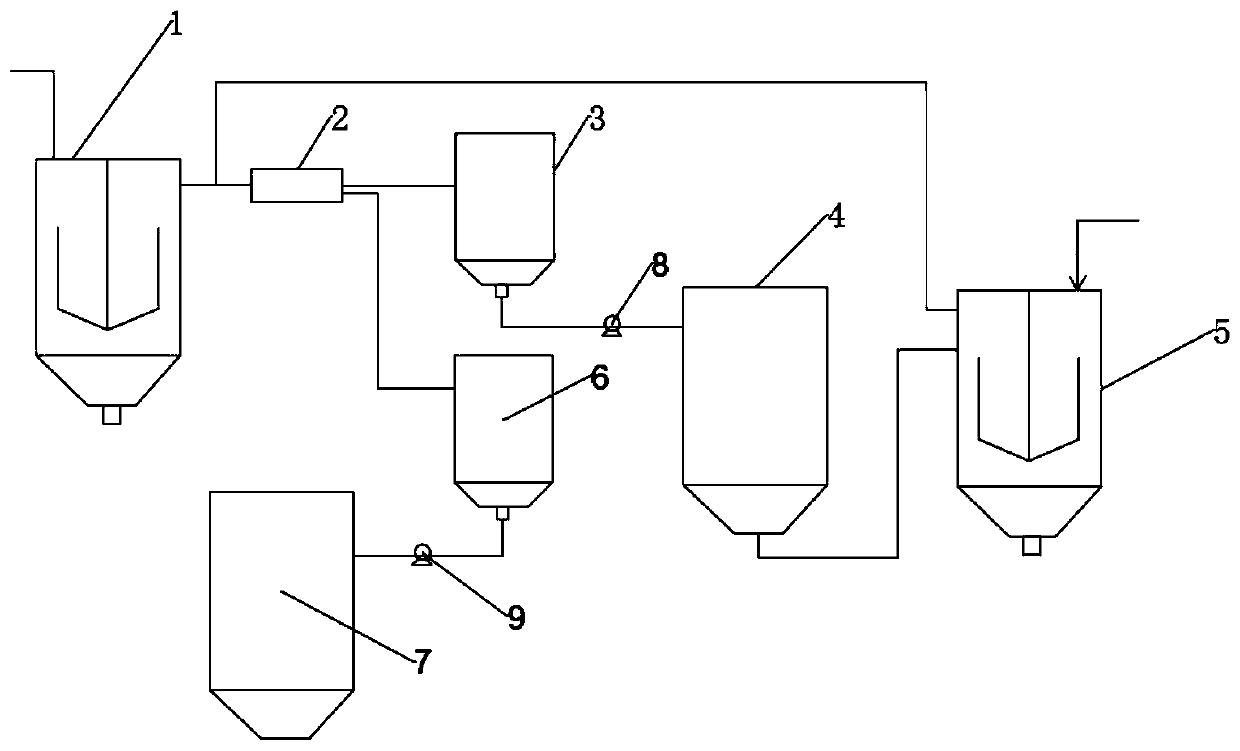

[0041] like figure 1 Shown, utilize the preparation method of organosilicon cracking oil residue to produce organosilicon mixed ring body, comprise the following steps:

[0042](a) Primary cracking: first chop the organosilicon cracking oil residue discharged from the hydrolysis cracking workshop and put it into the coarse cracking kettle 1, manually or mechanically cut it into regular 10cm×50cm×10cm, and the input amount is 100kg; then add 5wt% D. 4 , 5wt% KOH aqueous solution is reacted, and the mass concentration of KOH aqueous solution is 50%;

[0043] (b) After the feeding is completed, the heat conduction oil system is used to heat up the crude cracking kettle 1, and the temperature is raised in two stages. When the temperature of the cracking kettle reached 120°C, the stirring device in the crude cracking kettle 1 and the vacuum pump 2 connected to the crude cracking kettle 1 were started at the same time. 130m 3 / h, the feed liquid extracted by the vacuum pump 2 is...

Embodiment 2

[0050] This embodiment is modified on the basis of embodiment 1, specifically, the addition of KOH aqueous solution in the step (a) is 10 wt%, and the rest of the steps are the same as in embodiment 1.

Embodiment 3

[0052] This example is changed on the basis of Example 1, specifically, the amount of KOH aqueous solution added in the step (a) is 15 wt%, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com