A kind of method for preparing glycolide and cracking device thereof

A glycolide and pyrolysis kettle technology, which is applied in the field of biomedical materials and synthesis technology, can solve the problems of increasing costs and energy waste, and achieve the effects of environmental protection, cost saving, and uniform molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

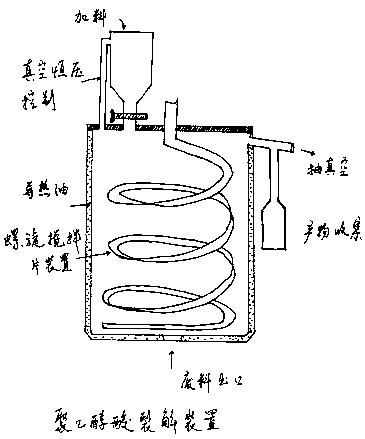

[0016] Embodiment 1: the making of polyglycolic acid cracking device

[0017] Made of stainless steel, according to the attached figure 1 The structure shown makes a polyglycolic acid pre-cracking device with a volume of 10 liters.

Embodiment 2

[0018] Embodiment 2: the precondensation of glycolic acid

[0019] In the glycolic acid precondensation device, add 6 kg of glycolic acid through the feeding funnel, then add 5 grams of stannous octoate, heat up to 100 ° C for 1 hour; then heat up to 140 ° C for 1 hour, and at the same time vacuum 20Kpa; continue to heat up React at 200°C for 0.5 hours, then reduce the vacuum pressure to 10Kpa; after the reaction is completed, use the lifting and stirring method to pulverize the polyglycolic acid into powder.

Embodiment 3

[0020] Embodiment 3: Cracking of polyglycolic acid

[0021] Mix the polyglycolic acid powder obtained in Example 2 with 40 grams of antimony trioxide, then add it to the cracking device of polyglycolic acid through the feeding funnel, and batches are added during the feeding, and the amount of each feeding can be adjusted arbitrarily as required. Finished, the hopper is sealed, and the funnel piston is closed. Rapidly raise the temperature of the cracking kettle to 285°C by heating in an oil bath, and then open the funnel piston, so that the polyglycolic acid powder slowly enters the cracking kettle, and at the same time vacuumize, and the pressure drops to 2-5Kpa until the light yellow fraction is completely evaporated. The crude yield is greater than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com