Method for improving diamond coating deposition efficiency of hot filament CVD (chemical vapor deposition) based on magnetic confinement

A technology of magnetic confinement and deposition of gold, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of insufficient dissociation of reaction gas, low gas utilization rate, slow deposition rate, etc., to reduce cracking Time to absorb energy, prolong residence time, improve surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

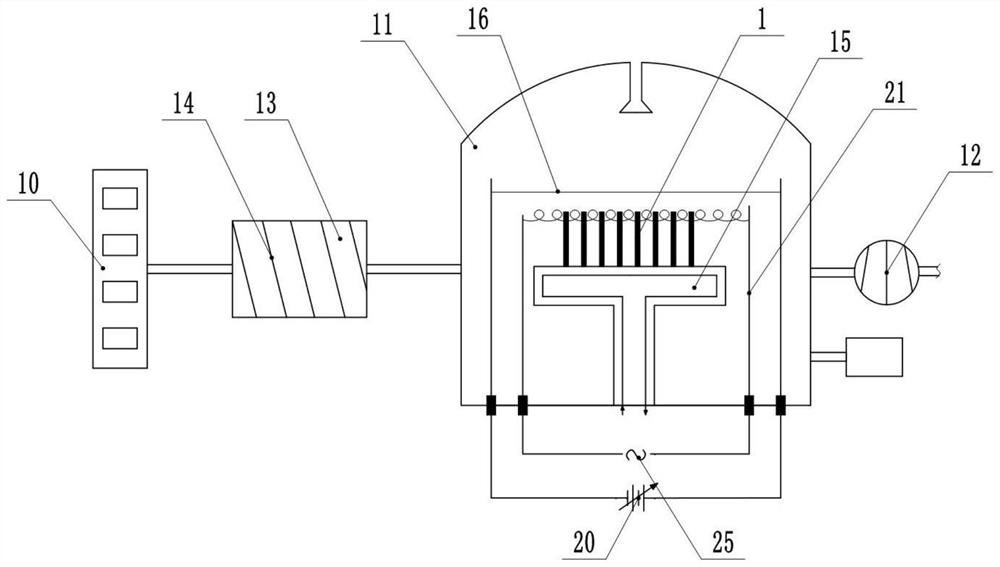

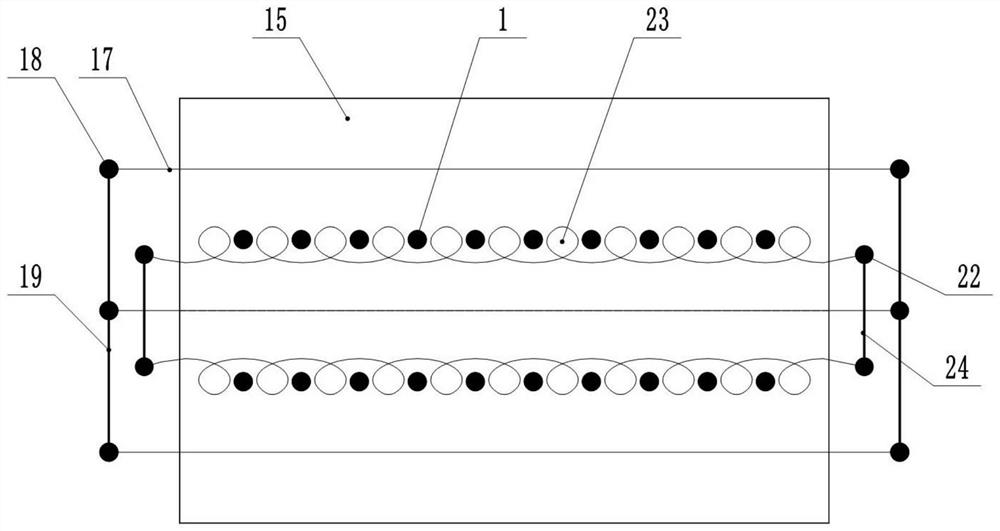

[0033] Based on the method of magnetic confinement to improve the efficiency of hot-wire CVD deposition of diamond coatings, this method uses an improved hot-wire CVD equipment, combined with figure 1 with figure 2 As shown, on the basis of the original hot wire CVD equipment, a gas mixing chamber 13 and a magnetic enhancement assembly 21 are added.

[0034] The original hot wire CVD equipment includes a gas source 10, a coating chamber 11 and a vacuum pump 12, wherein the gas source 10 provides hydrogen and low-concentration methane, ethanol, acetone, etc., and the gas mixing chamber 13 is arranged between the gas source 10 and the coating chamber Between the chambers 11 , a magnetic enhancement assembly 21 is disposed within the coating chamber 11 .

[0035] The gas mixing chamber 13 is a cylindrical structure, and its material is made of magnetically conductive and high temperature resistant materials. A heating element for heating it is provided on the gas mixing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com