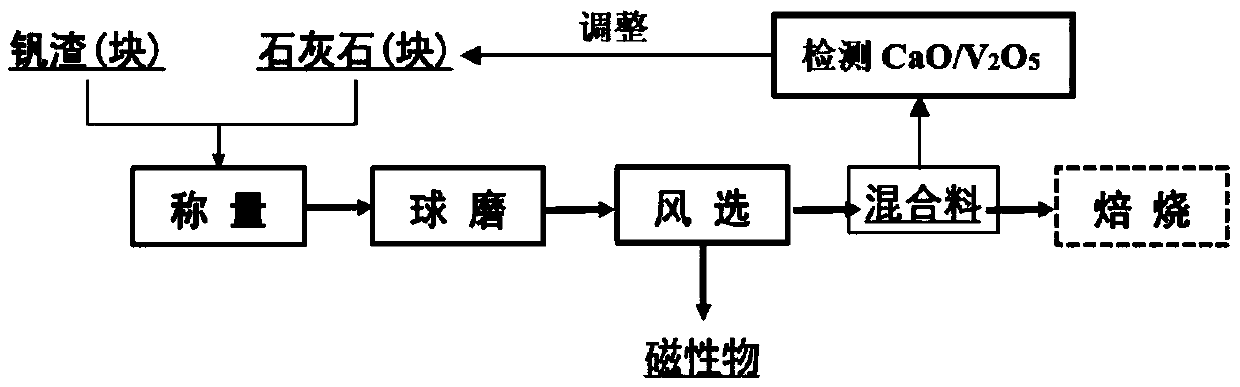

Method for preparing mixture by synchronously grinding and mixing vanadium slag and limestone in vanadium slag calcification vanadium extraction process

A mixture and limestone technology, applied in the field of metallurgy, can solve the problems of unstable index, low quality of mixture, and low yield of vanadium, and achieve the effects of stable product quality, reduction of vanadium slag overgrinding ratio, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw material of this embodiment:

[0026] Vanadium slag: V 2 o 5 The mass percentage is 19.15%, the CaO mass percentage is 2.28%, and the particle size is 1-10cm;

[0027] Limestone block: CaO mass percentage content is 54.21%, particle size is 1-6cm;

[0028] In the current industrial production system of vanadium slag ball mill air separation (a vanadium slag calcification vanadium extraction plant in China), the feed end of the ball mill is based on CaO / V 2 o 5 =0.62 mixes vanadium slag block and limestone block, carries out synchronous grinding and material mixing operation by ball mill system, obtains vanadium slag calcification and extracts vanadium mixture after the winnowing system again, and its quality is as shown in table 1 through repeated sampling analysis, By measuring the weight of the material, the yield of vanadium in the mixture is calculated to be 98.79%.

[0029] Table 1 The indicators of the mixture

[0030] CaO / V 2 o 5

Embodiment 2

[0032] The raw material of this embodiment:

[0033] Vanadium slag: V 2 o 5 The mass percentage is 15.76%, the CaO mass percentage is 3.65%, and the particle size is 1-10cm;

[0034] Limestone block: CaO mass percentage content is 54.21%, particle size is 1-6cm;

[0035] In the current industrial production system of vanadium slag ball mill air separation (a vanadium slag calcification vanadium extraction plant in China), the feed end of the ball mill is based on CaO / V 2 o 5 =0.62 add vanadium slag block and limestone block, carry out synchronous grinding and material mixing operation by ball mill system, then obtain vanadium slag calcification vanadium extracting mixture after air separation system, its quality is as shown in table 2 through multiple sampling analysis, By measuring the weight of the material, the yield of vanadium in the mixture is calculated to be 98.83%.

[0036] Table 2 The indicators of the mixture

[0037] CaO / V 2 o 5

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com