Automobile hub bearing fault feature extraction method based on optimal quality factor selection

A technology of automobile hub and fault features, which is applied in the field of fault feature extraction of automobile hub bearings, and can solve the problem of large random selection of quality factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

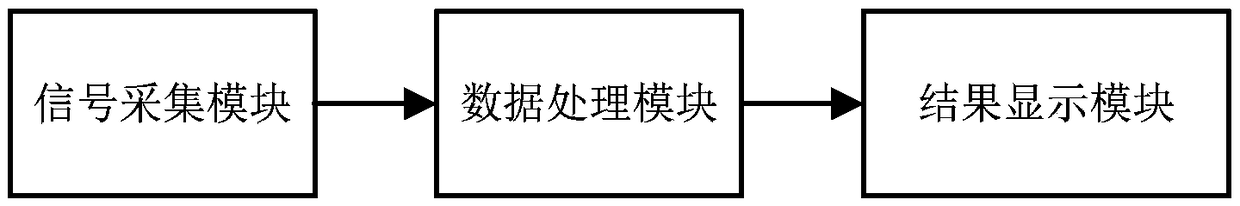

Method used

Image

Examples

Embodiment

[0076] First, select the automobile wheel bearing shown in Table 1. Then, cut a groove with a width of 0.3 mm and a depth of 0.05 mm in the outer ring of the bearing. Finally, install the acceleration sensor on the bearing seat to obtain the vibration signal x in the vertical direction.

[0077] Table 1 Parameters of wheel hub bearings

[0078] .

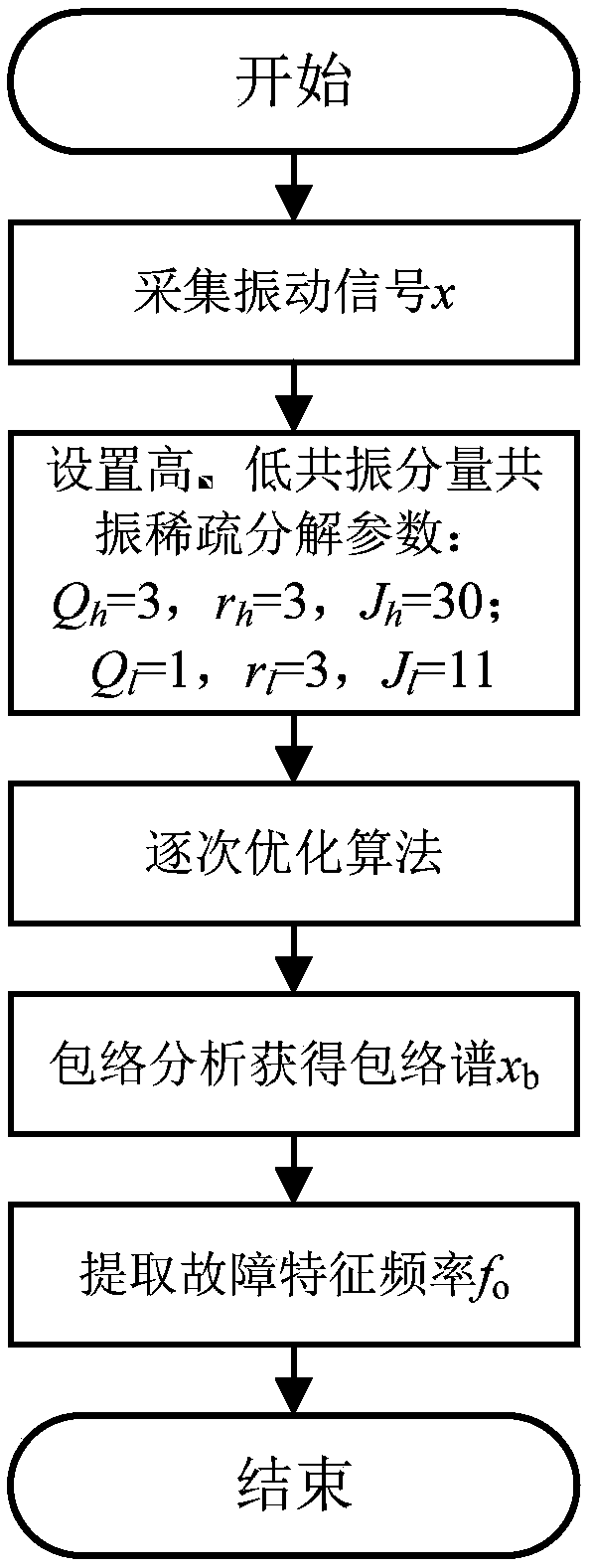

[0079] Step 1: The information collection module collects the vibration signal x of the automobile hub bearing through the acceleration sensor, the waveform is as Figure 4 Shown. Sampling frequency f s It is 100kHz, the sampling time t is 0.5s, and the number of sampling points N is 50000.

[0080] Step 2: The resonance sparse decomposition parameter initialization module sets the initial resonance sparse decomposition parameter Q h = 3, r h = 3, J h = 30; Q l = 1, r h = 3, J l = 11.

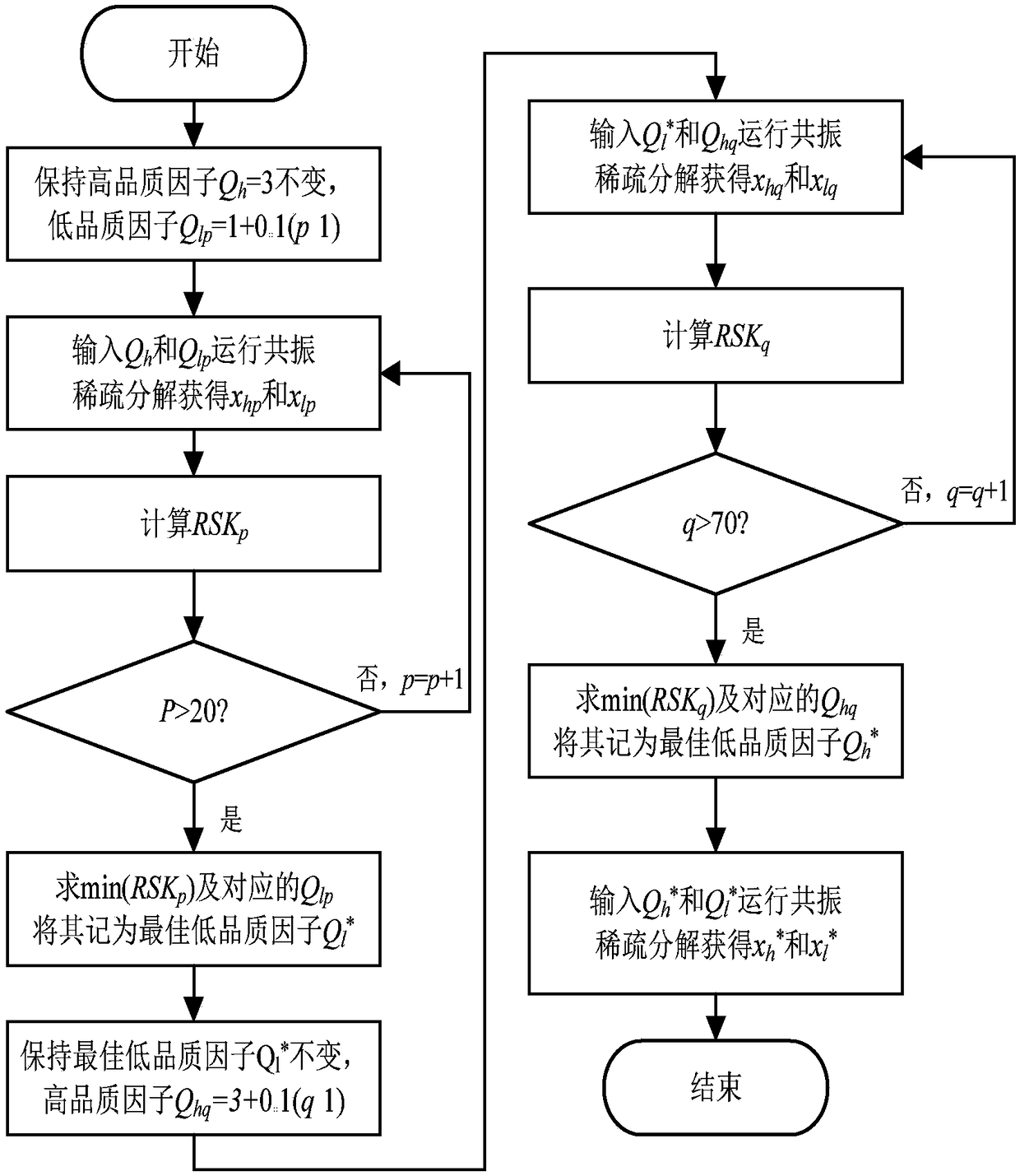

[0081] Step 3: The quality factor is optimized successively for high and low quality factors Q h And Q l Optimize and find the best quality factor as Q h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com