A pretreatment method for the determination of mercury in plant-derived samples

A plant-derived, element determination technology, applied in the field of heavy metal detection, can solve the problems of high energy consumption and high digestion temperature, and achieve the effects of reducing the amount of strong acid, improving accuracy, and alleviating foaming and splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

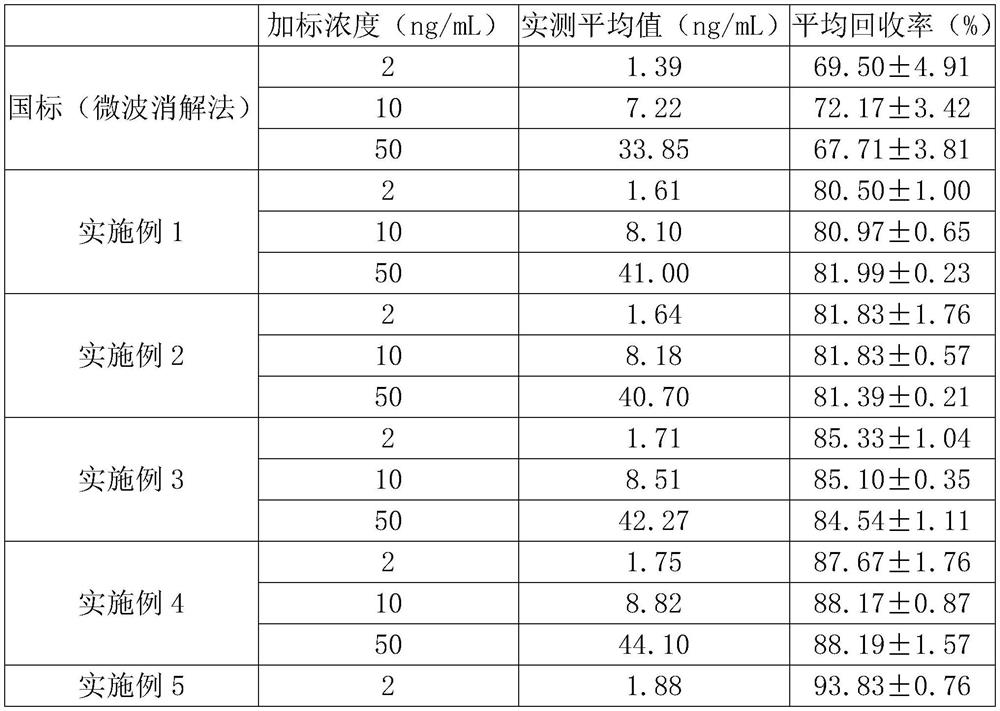

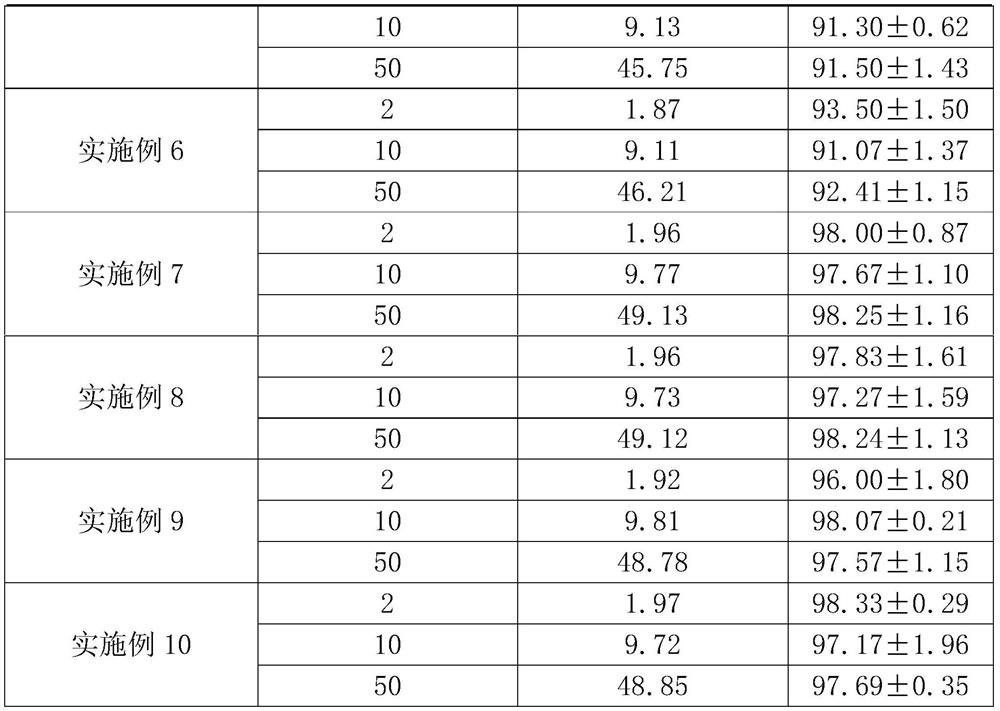

Examples

Embodiment 1

[0026] A pretreatment method for determination of mercury in plant-derived samples, comprising the following steps:

[0027] 1) Take the onion, pulverize it, beat it, weigh 0.5g of the beaten sample, add 1.0mL of concentrated sulfuric acid with a mass fraction of 70%, place it in a graphite porous electrothermal digestion apparatus, keep the temperature at 10°C, and hold it for 0.3h;

[0028] 2) Add 2.0mL of digestion solution a, and keep the temperature at 90°C until the total volume is reduced by 50%; then add 3.0mL of sulfuric acid solution with a mass fraction of 75% for 0.3h;

[0029] 3) Add 1.0mL of digestion solution b, cool down to 65°C at a rate of 3°C / min, keep it warm for 0.5h, then rinse with acid, constant volume, and test;

[0030] The digestion solution a is HNO 3 and HClO 4 Mixture of HNO 3 with HClO 4 The mass ratio is 3:1;

[0031] The digestion solution b is HNO 3 , HCl and HClO 4 Mixture of HNO 3 , HCl and HClO 4 The mass ratio is 7:2:1.

Embodiment 2

[0033] A pretreatment method for determination of mercury in plant-derived samples, comprising the following steps:

[0034] 1) Take the onion, pulverize it, beat it, weigh 4.0g of the beaten sample, add 1.5mL of concentrated sulfuric acid with a mass fraction of 75%, keep the temperature at 15°C, and hold for 0.5h;

[0035] 2) Add 4.0mL of digestion solution a, and keep the temperature at 105°C until the total volume is reduced by 60%; then add 1.0mL of sulfuric acid solution with a mass fraction of 30% for 0.2h;

[0036] 3) Add 2.0mL of digestion solution b, cool down to 75°C at a rate of 5°C / min, keep it warm for 1.5h, then rinse with acid, constant volume, and test;

[0037] The proportion and dosage of the digestion solutions a and b are the same as in Example 1.

Embodiment 3

[0039] A pretreatment method for determination of mercury in plant-derived samples, comprising the following steps:

[0040] 1) Take the onion, pulverize it, beat it, weigh 2.0g of the beaten sample, add 1.5mL of concentrated sulfuric acid with a mass fraction of 70%, keep the temperature at 15°C, and hold for 0.5h;

[0041] 2) Add 3.0mL of digestion solution a, and keep the temperature at 105°C until the total volume is reduced by 60%; then add 3.0mL of sulfuric acid solution with a mass fraction of 75% for 0.3h;

[0042] 3) Add 2.0mL of digestion solution b, cool down to 65°C at a rate of 3°C / min, keep it warm for 1.0h, then rinse with acid, constant volume, and test;

[0043] The proportion and dosage of the digestion solutions a and b are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com