Quantitative detection method for adhesiveness of asphalt and aggregate

A quantitative detection method and adhesion technology, applied in the direction of removing a certain component weighing, measuring device, material weighing, etc., can solve the problems of ambiguity, inability to quantitatively detect, and uncertainty in the test conditions of the boiling method, and achieve It is suitable for promotion, the calculation formula is easy to understand, and the operation process is simple.

Inactive Publication Date: 2018-12-28

SOUTHEAST UNIV +1

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The test speed of the water boiling method is fast, the particles are large, the asphalt peels off obviously, and it is easy to observe, and most of the raw aggregates have aggregates with a maximum particle size greater than 13.2mm, so the water boiling method is mostly used to test the adhesion of asphalt and aggregates , but because the test conditions of the boiling method are vague, uncertain, and not strict, it brings great differences to the test results; It is determined by the visual judgment of experienced testers, and is greatly affected by human observation factors, so it cannot be quantitatively detected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

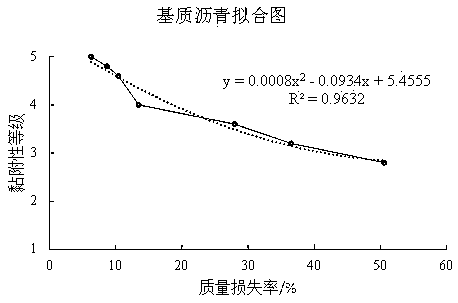

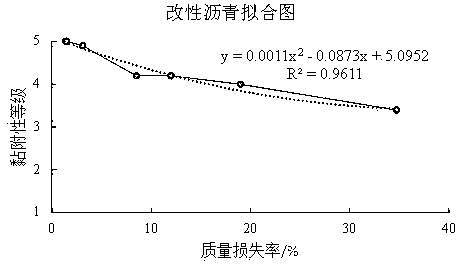

The invention relates to a quantitative detection method for the adhesiveness of asphalt and aggregate. The method comprises the following steps that: A: selecting five pieces of regular aggregate ofwhich the particle size is 13.2-19mm, cleaning, drying and weighing the aggregate, dipping the aggregate into preheated asphalt (a drying oven at a temperature of 160DEG C to be kept warm for 2.5h), and quickly stirring the aggregate to enable the asphalt on the surfaces of stones to be evenly coated; B: taking out the stone coated with the asphalt, cooling to the room temperature, weighing the stone, putting in a clean glass bottle, and weighing the total mass; C: filling the glass bottle with water, sealing the bottle glass, putting in a 90-DEG C constant temperature water bath box to be heated for 1 h, and taking out the glass bottle; D: pouring out mixed liquid in the bottle, drying, weighing the total mass of the stone subjected to the water bath and the stone; and E: according to a mass change before and after the water bath, calculating the quality loss rate of the asphalt on the surface of the stone, and judging an adhesiveness level. The method is clear in conditions and simple in operation, through a quantitative method, the adhesiveness between the asphalt and the aggregate is detected, and the influence of subjective human factors is avoided.

Description

technical field The invention relates to the technical field of performance detection of road building materials, and relates to a quantitative detection method for the adhesion between asphalt and aggregates. Background technique As the binder of asphalt mixture, asphalt binds various aggregates together, making the mixture a complete stress-bearing body. When it rains or water accumulates on the road surface, the asphalt pavement is soaked in water for a long time, and the water will enter the pavement structure layer through the gaps between the asphalt pavement materials, thereby reducing the bonding force between the asphalt pavement materials and causing the asphalt to fall from the surface of the adhered material. Peeling; under the circulation of hydrodynamic pressure, water repeatedly scours the pavement, which causes the asphalt film to peel off from the surface of the material, and finally forms pits and other diseases under the long-term traffic load, which is ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N5/04G01N5/00

CPCG01N5/00G01N5/04

Inventor 陈小兵刘晗孔德羽张小飞骆明金陆秀英王振杰

Owner SOUTHEAST UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com