Five-axis hybrid machine tool for machining cylindrical parts

A five-axis mixed-connection and component technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manipulators, etc., can solve the problem of less design of machining cylindrical machine tools, and achieve a wide processing range, high precision, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

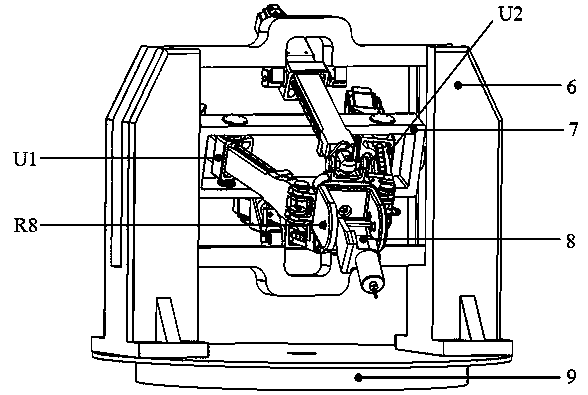

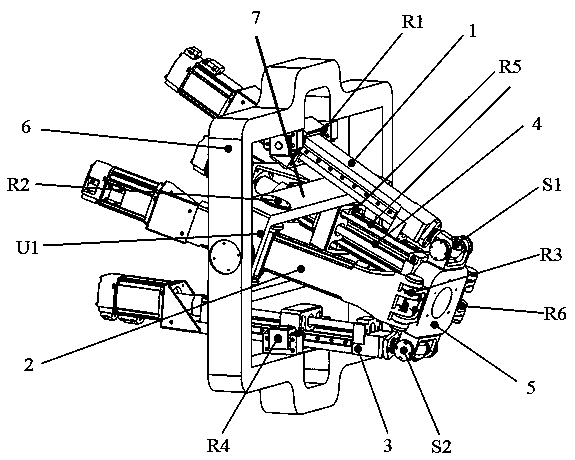

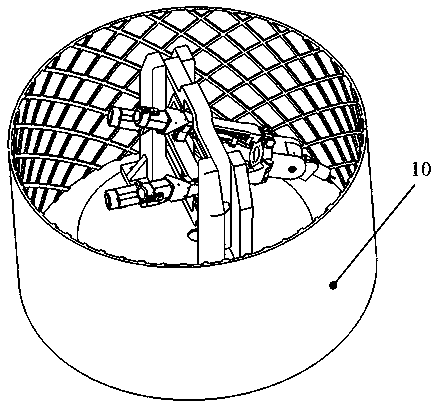

[0029] Such as Figure 1-8As shown, a five-axis hybrid machine tool for processing cylindrical parts, including a single-degree-of-freedom rotating head, a rotating base, a frame, a motion platform, a shaft frame, the first branch chain, the second branch chain, and the third branch chain and the fourth branch chain; the rotating shaft frame is arranged in the frame, the motion platform is connected with the rotating shaft frame through the second branch chain and the fourth branch chain, and the rotating shaft frame is connected with the frame through the rotating pair of the shaft frame, The motion platform is connected with the frame through the first branch chain and the third branch chain; the single-degree-of-freedom rotor is fixedly connected with the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com