Electronic control stapler and using method thereof

An electronic control and stapler technology, which is applied in binding and other directions, can solve the problems of less number of staples in binding, slow binding efficiency, difficult control of the number of staples, etc., and achieve the effect of simple structure, good binding effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

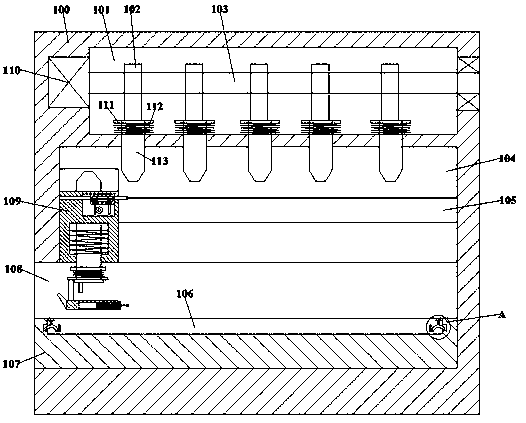

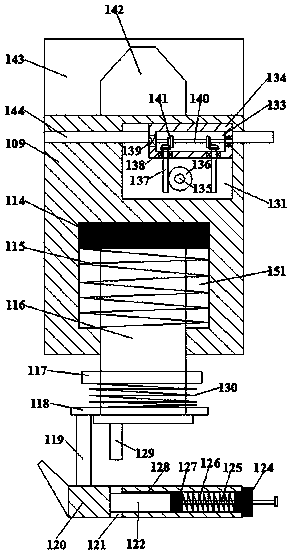

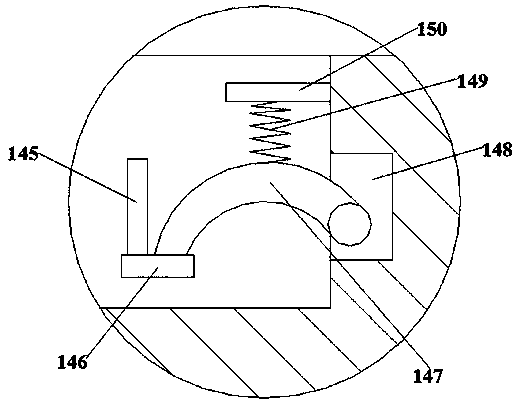

[0020] Such as figure 1 , figure 2 with image 3As shown, the electronically controlled stapler of the present invention and its use method include a body 100 and a transposition chamber 104 arranged in the body 100, and the bottom of the transposition chamber 104 communicates with an opening left for loading Cavity 108, the top of the transposition cavity 104 is provided with a first cavity 101, and the front and rear inner walls of the transposition cavity 104 are communicated with symmetrical tooth grooves 105, and the transposition cavity 104 is slidingly connected with a drive carrier 109, the drive carrier 109 is provided with a second cavity 131, the second cavity 131 is rotatably connected with a first rotating shaft 135 extending forward and backward, and the front and rear ends of the first rotating shaft 135 pass through the drive The front and rear end surfaces of the carrier 109 are provided with gears meshingly connected with the tooth grooves 105, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com