Construction and operating method inside elevator shaft

A technology for elevator shafts and construction platforms, which is applied in the direction of housing structure support, housing structure support, and scaffolding supported by housing structure, etc. It can reduce the difficulty of construction, improve the construction environment, and improve the stability and safety of construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with embodiment.

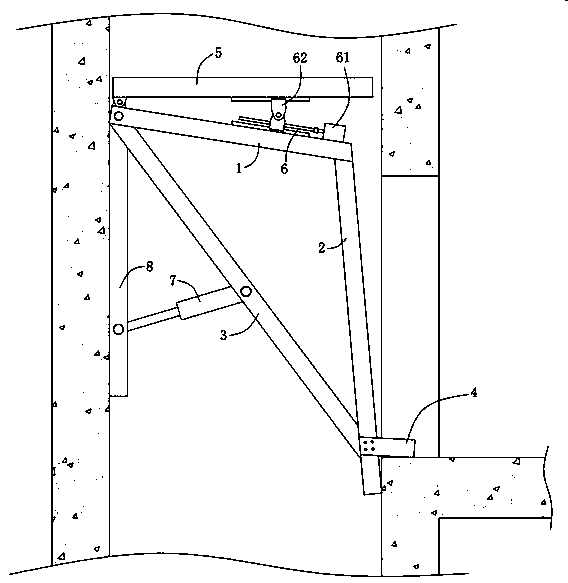

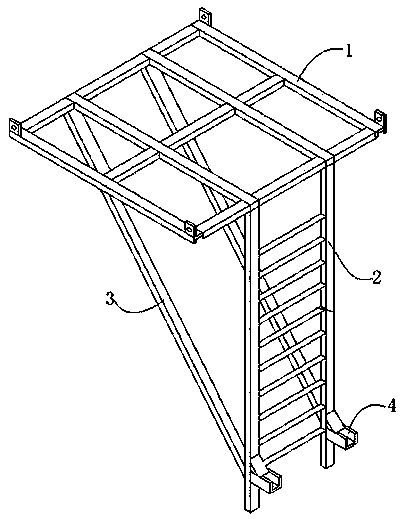

[0025] During specific implementation: if figure 1 As shown, a self-leveling operation platform includes a horizontally arranged and rectangular top frame 1 as a whole, and a vertical support frame 2 is fixedly installed on one side of the top frame 1, and the top frame 1 and the support frame 2 is fixedly installed with a diagonal brace 3, the lower end of the diagonal brace 3 is connected to the lower end of the support frame 2, and the upper end is connected to the side of the top frame 1 away from the support frame 2; the support The position near the bottom of the frame 2 has a corbel 4 arranged in a direction away from the diagonal brace 3, and the top frame 1 is also provided with lifting lugs for lifting; the connection between the top frame 1 and the support frame 2 The angle between them is greater than 90°, so that when the upper ends of the corbels 4 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com