Harvester for panax notoginseng stems and leaves

A harvester, stem and leaf technology, applied in the direction of harvester, agricultural machinery and implements, applications, etc., to achieve the effect of improving transplanting quality, simple structure, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

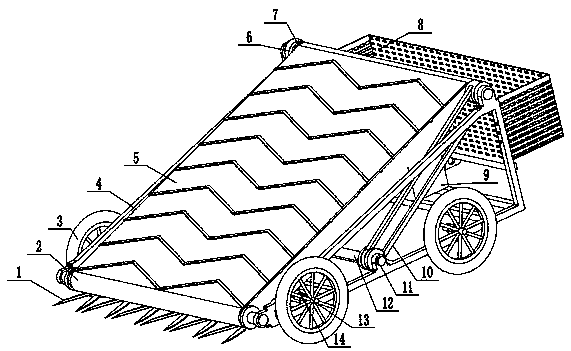

[0029] Embodiment 1: as Figure 1-10 As shown, a Panax notoginseng stem and leaf harvester includes a shearing knife 1, a driven transmission shaft 2, a traveling wheel 3, a frame 4, a conveyor belt 5, a belt I 6, a driving transmission shaft 7, a collection box 8, and a transmission box 9. Belt Ⅱ10, secondary transmission shaft 12, connecting rod 13, guide rail 15, belt Ⅲ16, grooved cam 17, camshaft 18, hinged rod 21, reduction box 22, pulley Ⅱ23, pulley Ⅲ25, roller follower Part 26, groove 27 and slide block 30;

[0030] The driving transmission shaft 7, the secondary transmission shaft 12 and the driven transmission shaft 2 are fixed on the frame 4 in turn, the secondary transmission shaft 12 and the driven transmission shaft 2 are positioned at the bottom of the frame 4, and the driving transmission shaft 7 is positioned at the bottom of the frame 4. Obliquely above the driving transmission shaft 2 and the secondary transmission shaft 12, the driving transmission shaft 7 ...

Embodiment 2

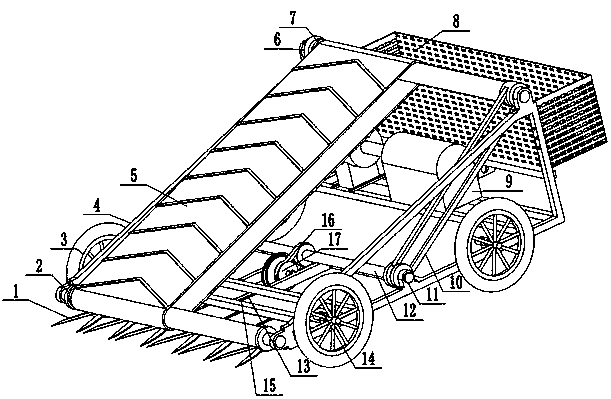

[0034] Embodiment 2: as Figure 2-4 As shown, the driving transmission shaft 7, the driven transmission shaft 2 and the secondary transmission shaft 12 are all fixed on the frame 4 through the bearing 11, and the two ends of the driving transmission shaft 7 are respectively fixed with a pulley Ⅳ 34 and a pulley Ⅴ 35 , One end of the secondary transmission shaft 12 is fixed with a pulley I19, the pulley I19 and the pulley V35 are connected through the belt II10, and the pulley IV34 is connected with the output shaft wheel of the reduction box 22 through the belt I6.

[0035] Such as Figure 6As shown, there are symmetrical holes II 28 on both sides of the side of the frame 4 close to the drive shaft 7, and the external power device is fixedly connected to the frame 4 through the hole II 28. The power device can be a common power supply mechanism in agricultural equipment such as tractors. , The power provided by the power unit is transmitted step by step through the belt wheel...

Embodiment 3

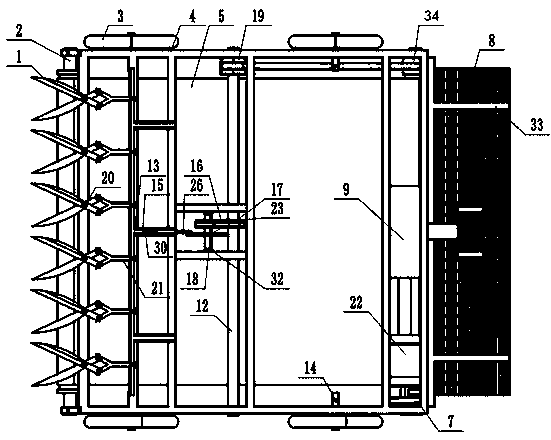

[0037] Embodiment 3: as image 3 As shown, in this embodiment, the camshaft 18 is fixed on the frame 4 through two diamond-shaped bearings 32, the camshaft 18 need not be set to be consistent with the width of the bottom of the frame 4, and the frame 4 is a frame with an inclination structure, the bottom of which is provided with multiple connecting rods to facilitate the fixing of other components.

[0038] Such as Figure 10 As shown, the connecting rod 13 includes two parts perpendicular to each other, wherein Figure 10 In the middle, a vertical connecting rod and three horizontal connecting rods vertically connected to it are arranged. The bottoms of the three horizontal connecting rods are all connected to the corresponding rails 15 through sliders 30, and the ends of the horizontal connecting rods in the middle are welded with rollers. The sub-follower 26 and the roller follower 26 are embedded in the groove 27 of the grooved cam 17; there are 6 holes I24 on the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com