A method for dismantling and recycling scrapped vehicles

A recycling method and vehicle technology, applied in solid waste removal, chemical instruments and methods, wet separation, etc., can solve the problems of inability to carry out refined disassembly, low efficiency, and high labor intensity, so as to improve practicability, Improve efficiency and improve crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

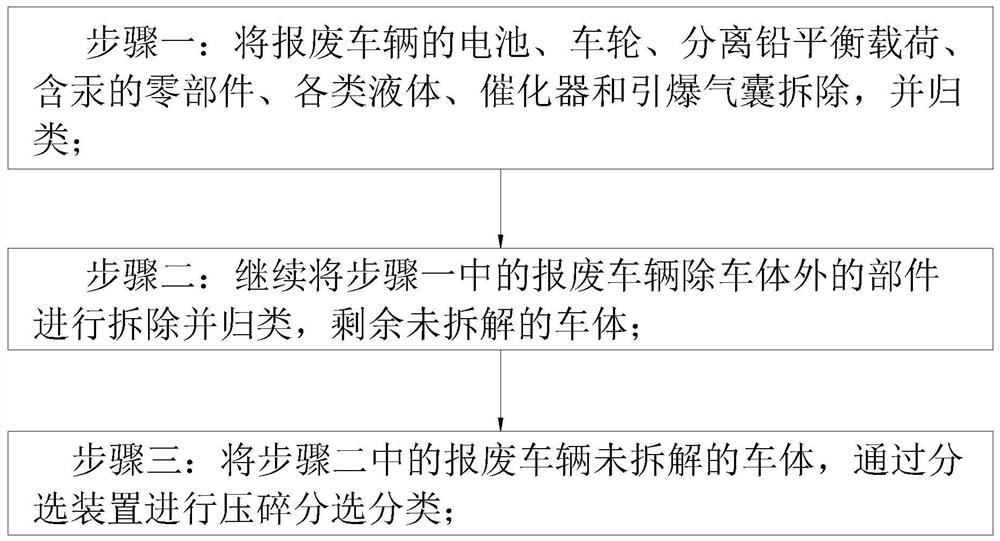

[0024] Such as Figure 1 to Figure 3 Shown, a kind of dismantling recovery method of scrapped vehicle of the present invention, this method adopts the following steps:

[0025] Step 1: Remove batteries, wheels, separated lead balance loads, mercury-containing parts, various liquids, catalytic converters and detonated airbags of scrapped vehicles and classify them;

[0026] Step 2: Continue to dismantle and classify the parts of the scrapped vehicle in step 1 except for the car body, leaving the undismantled car body;

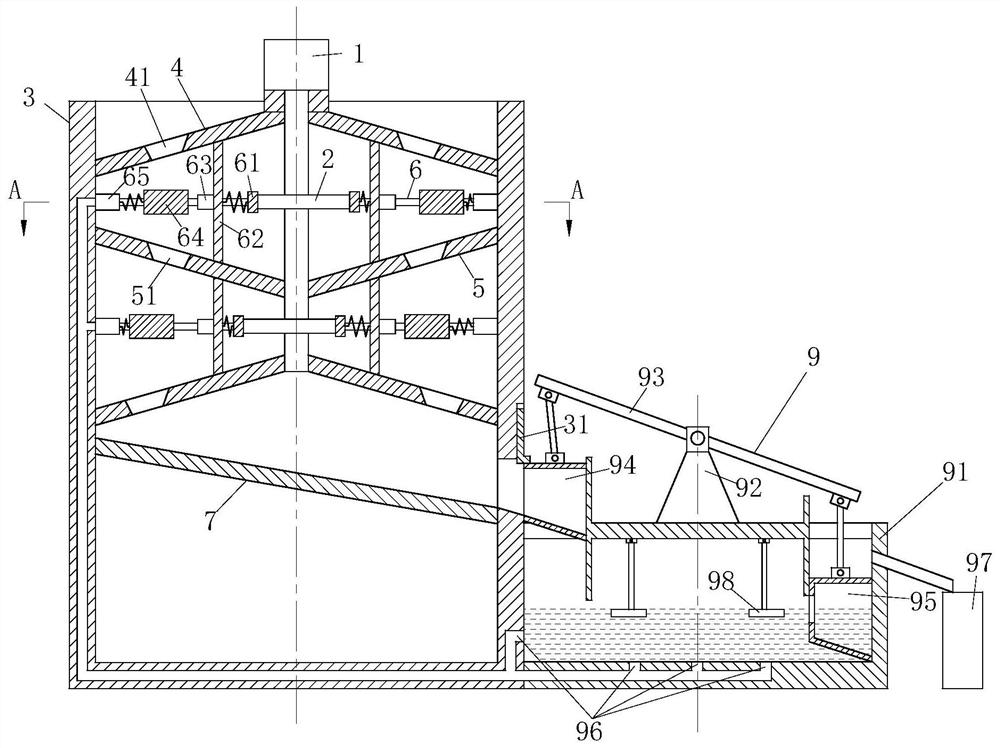

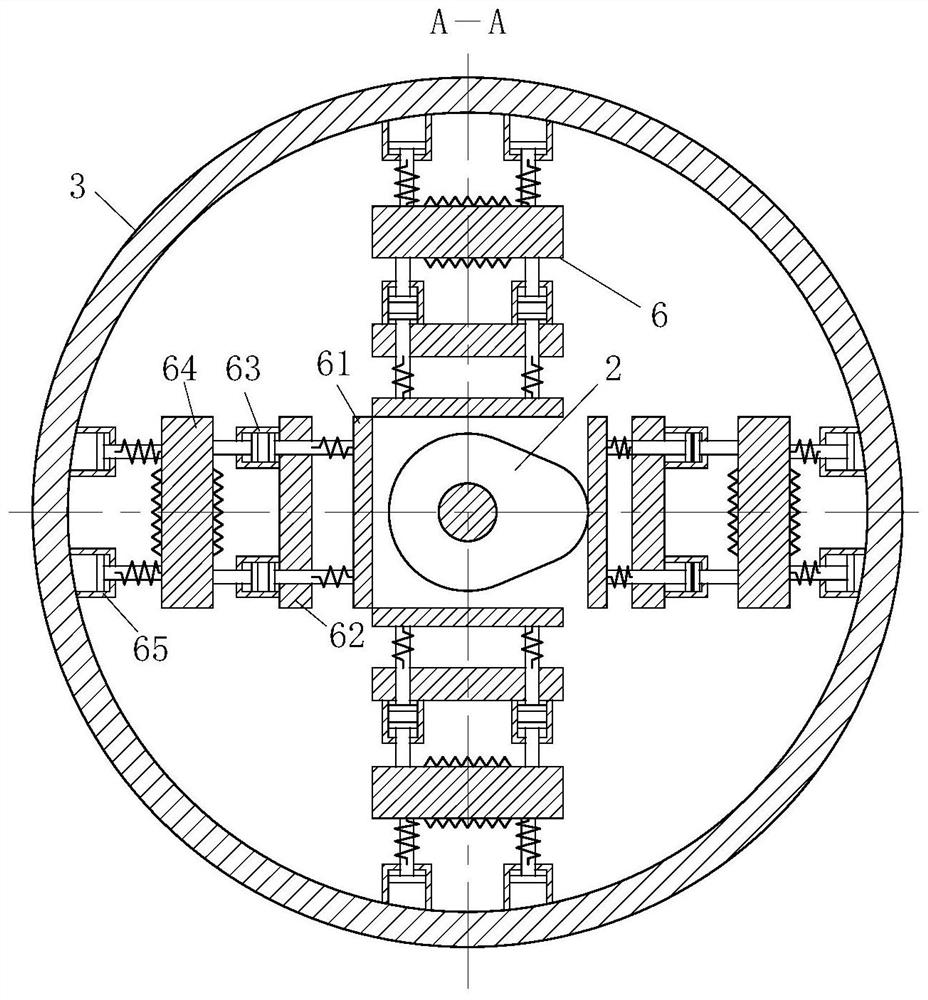

[0027]Step 3: crushing, sorting and sorting the undismantled body of the scrapped vehicle in step 2 through a sorting device;

[0028] Wherein, the sorting device includes a motor 1, a cam 2, a cylinder body 3, a first disc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com