Device and method for removing burrs in workpiece oil channel holes

A technology for oil passage holes and workpieces, which is applied in the field of devices for removing burrs in oil passage holes of workpieces, can solve the problems of difficult to remove completely in places with weak flushing force, difficult to achieve complete removal effect, complicated internal structure, etc. Potential safety hazards, simplified structure, and the effect of reducing hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

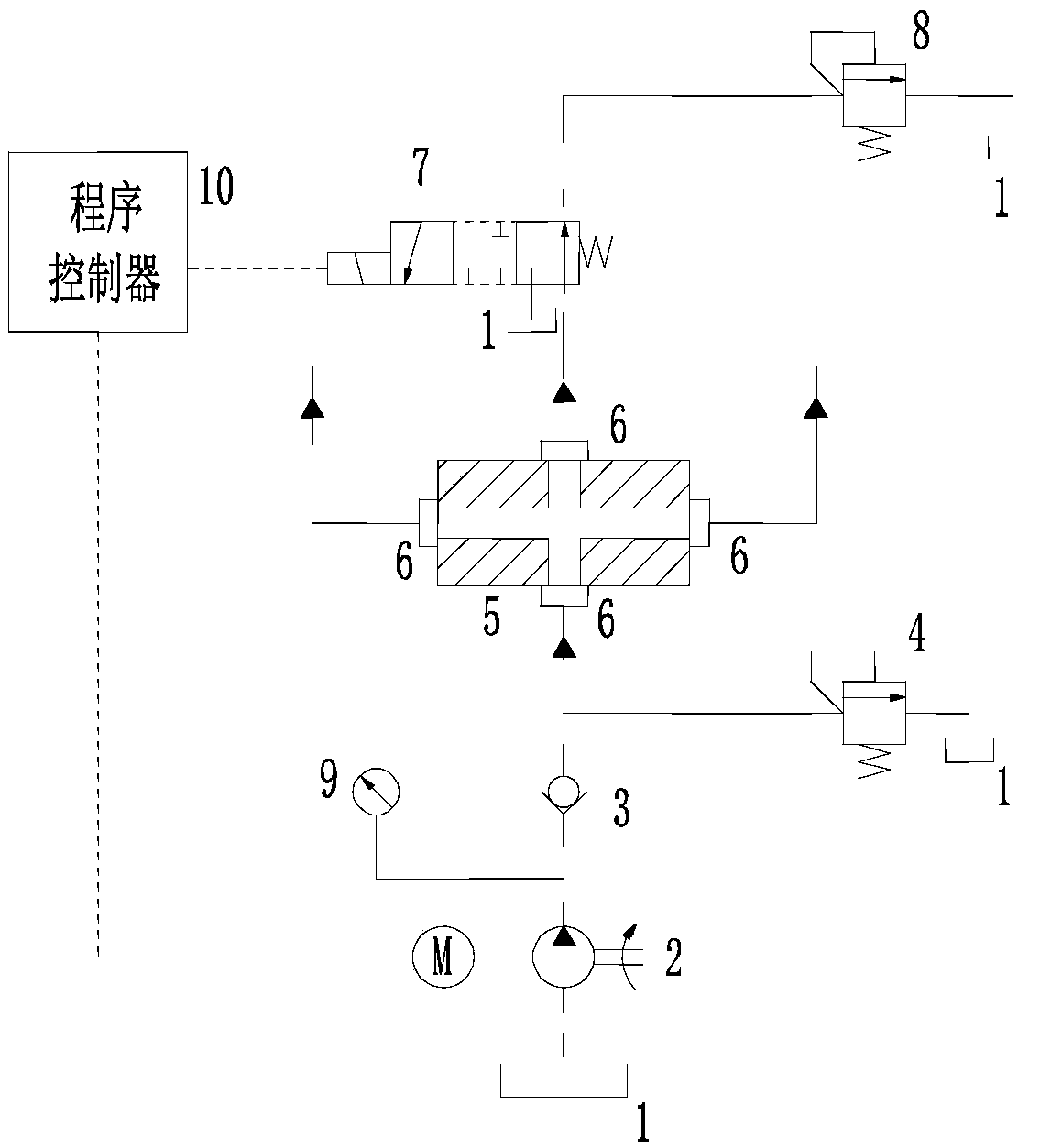

[0038] This embodiment provides a device for removing burrs in oil passage holes of a workpiece 5. The applicable workpiece 5 includes a plurality of oil passage holes, and the plurality of oil passage holes communicate with each other. like figure 1 As shown, the device for removing burrs in the oil passage hole of the workpiece 5 includes: a liquid inlet end and a liquid outlet end.

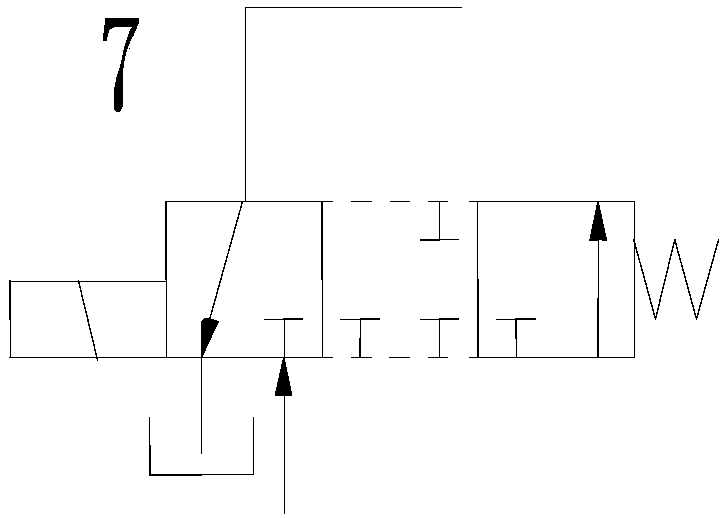

[0039] The liquid inlet end includes a hydraulic pump 2, a one-way valve 3, and a liquid inlet pipe (not shown in the figure). One end of the liquid inlet pipe is connected to the one-way valve 3, and the other end of the liquid inlet pipe is connected to at least one oil passage hole of the workpiece 5. ; The hydraulic pump 2 pumps the liquid from the mailbox 1 through the one-way valve 3 into the oil passage hole in the workpiece 5, and flows to the liquid outlet. The liquid passes through the hydraulic pump 2 to the one-way valve 3, and a pressure gauge 9 is set to monitor the pressure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com