Water purification system and cleaning method thereof

A water purification system and pure water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of short flushing time, limited shear force, and low flushing water flow rate and other problems, to achieve the effect of strong flushing, slow down pollution and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

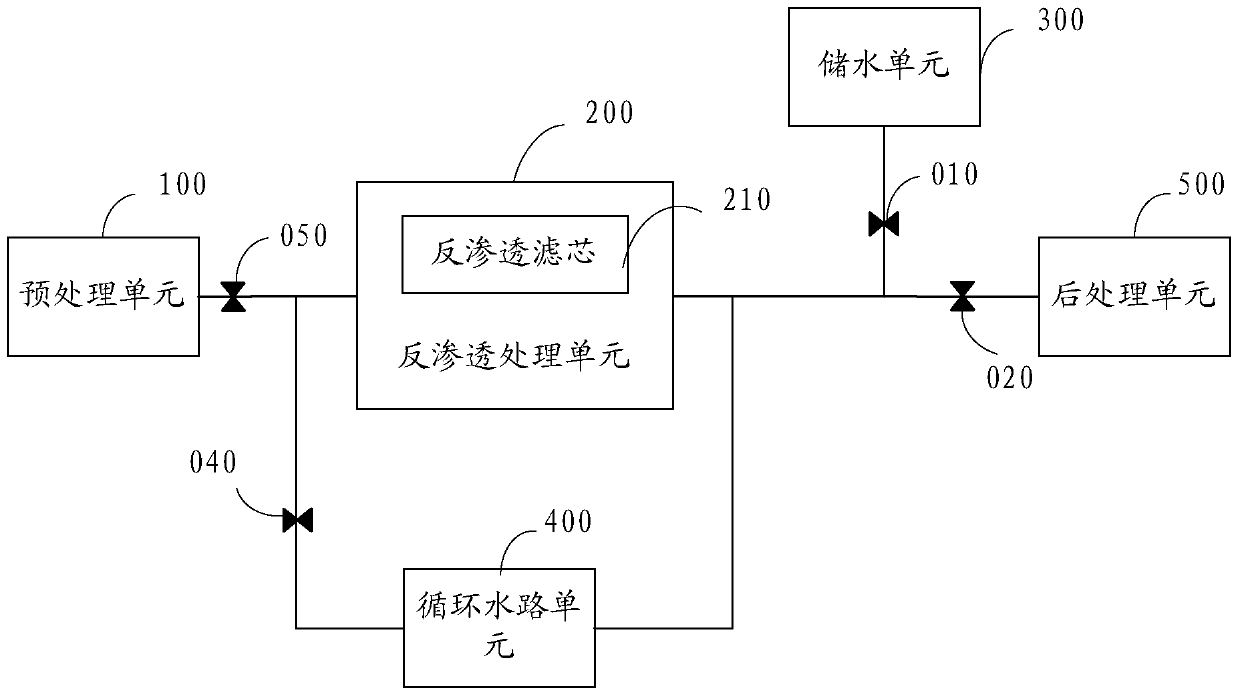

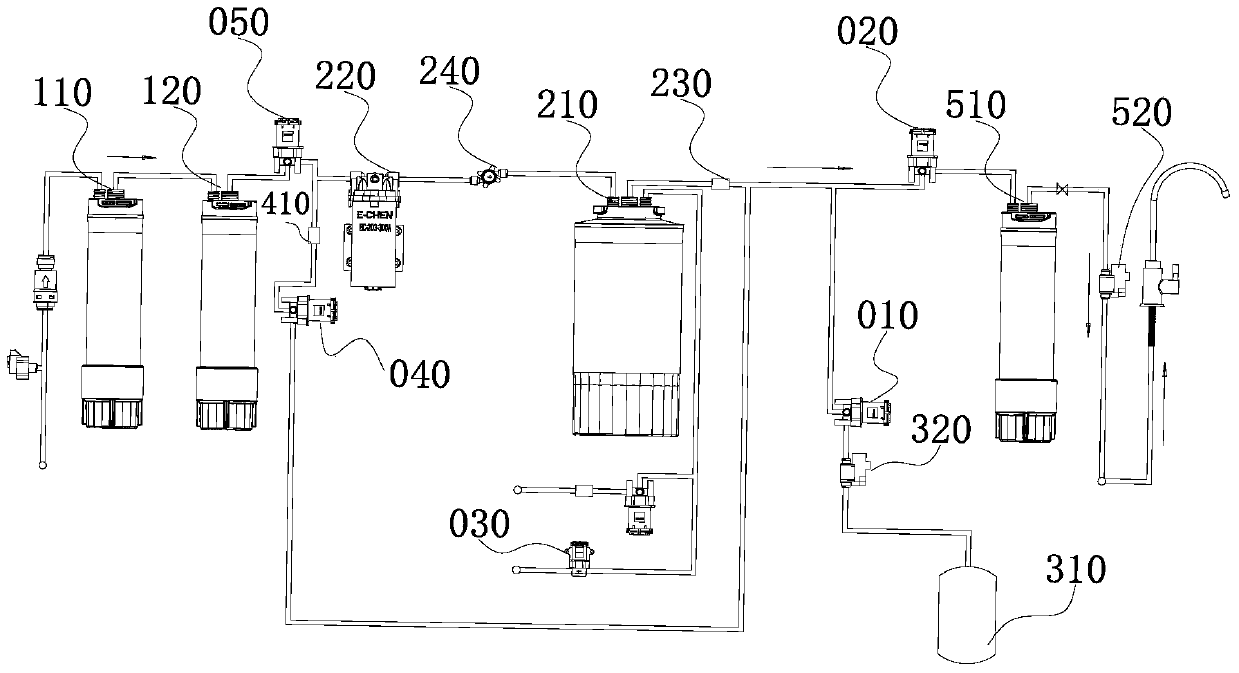

[0040] Such as figure 1 As shown, the water purification system provided by an embodiment of the present invention includes a pretreatment unit 100 , a reverse osmosis treatment unit 200 , a water storage unit 300 and a circulating water unit 400 . The reverse osmosis treatment unit 200 includes a reverse osmosis filter element 210 for filtering the water flowing through the reverse osmosis treatment unit 200 .

[0041] Wherein, the pretreatment unit 100, the reverse osmosis treatment unit 200, and the water storage unit 300 are connected in series through pipelines in sequence. During water production, the raw water (tap water) is treated by the pretreatment unit 100, then flows through the reverse osmosis filter eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com