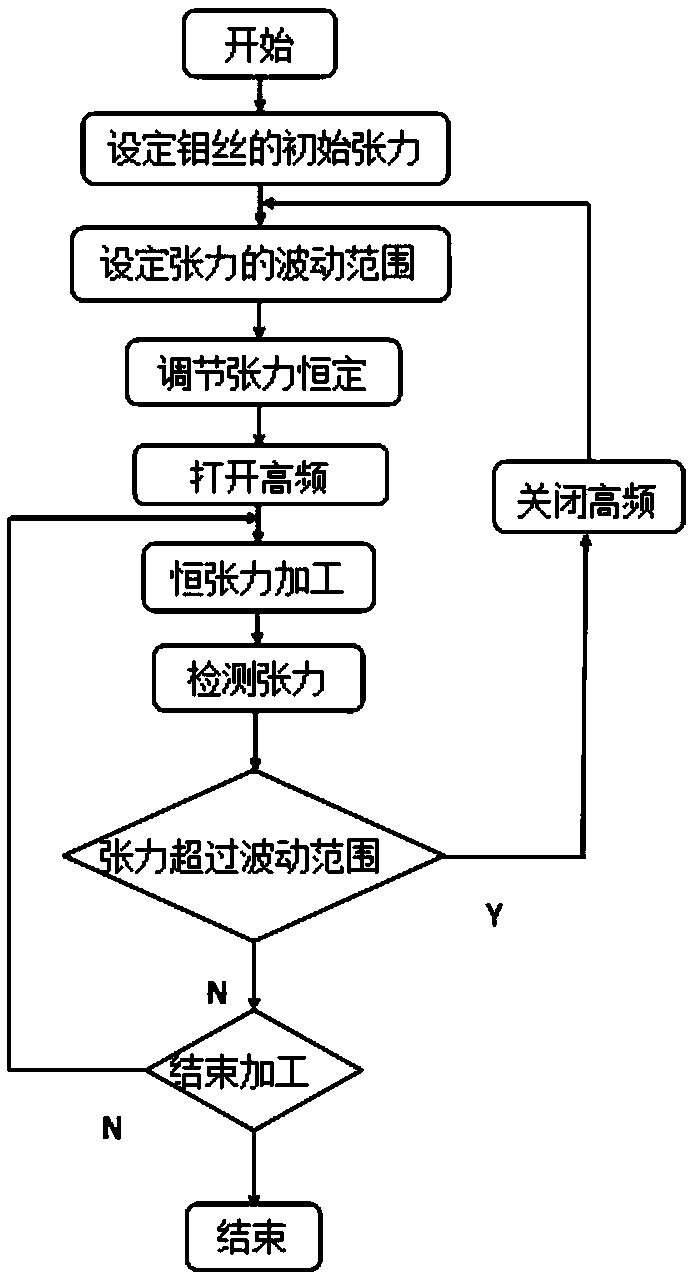

Wire cutting machining method and device for maintaining constant tension of molybdenum wire in process of machining

A processing method and processing technology, applied in the field of wire electric discharge processing, can solve the problems of adjustment lag, etc., and achieve the effect of solving adjustment lag, good stability, and realizing constant tension processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

[0025] The basic principles, main features and advantages of the present invention have been shown and described above. Those skilled in the art should understand that the present invention is not limited by the above-mentioned embodiments. What are described in the above-mentioned embodiments and the description are only the principles of the present invention. Variations and improvements, which fall within the scope of the claimed invention. The scope of protection required by the present invention is defined by the appended claims and their equivalents.

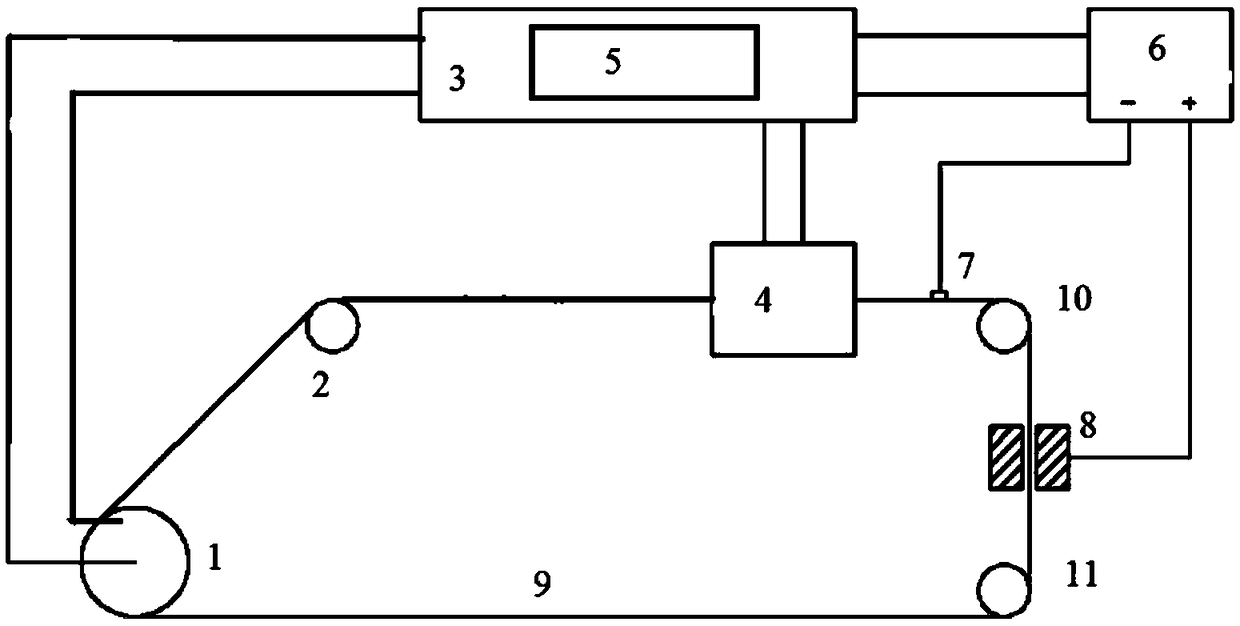

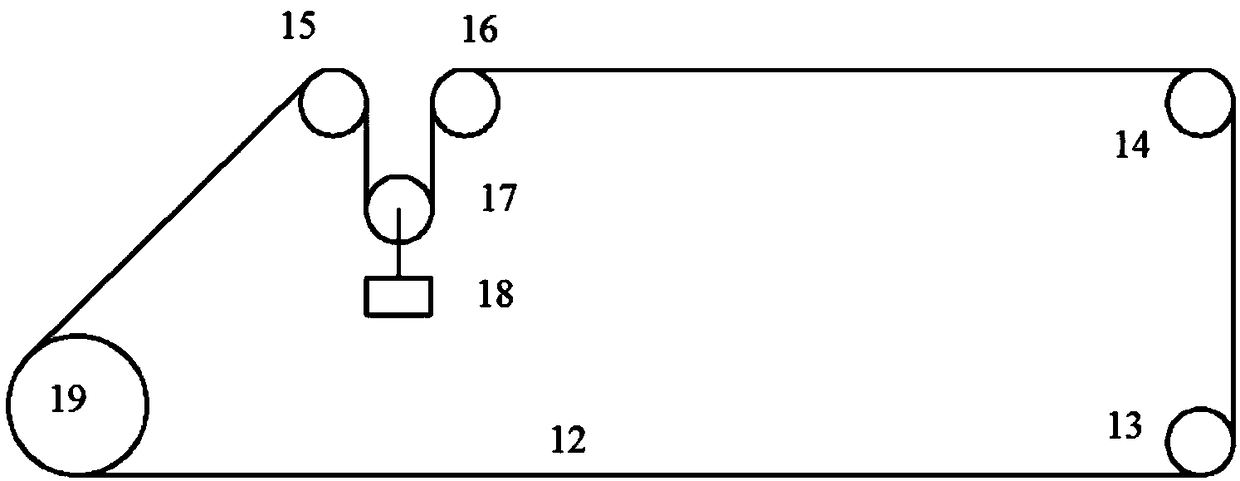

[0026] refer to figure 1 , a wire cutting device for maintaining constant molybdenum wire tension during processing, the device includes a wire stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com