Vehicle wheel spoke machining method

A processing method and spoke technology, applied to wheels, spoke wheels, vehicle parts, etc., can solve problems such as waste, large raw material reserves, and limited width of purchased raw materials, and achieve the effect of reducing processing costs and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

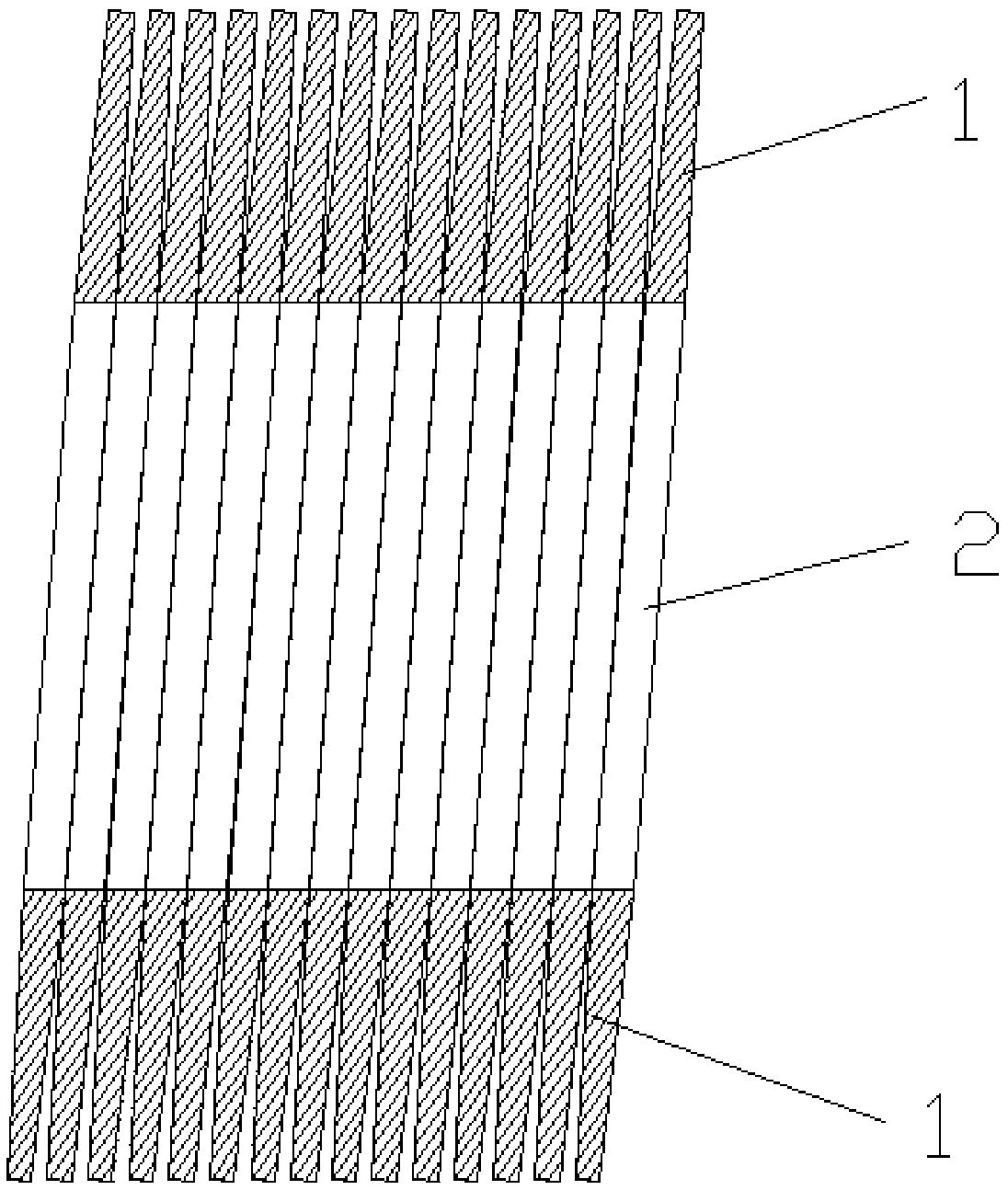

[0017] Such as Figure 1-Figure 2 As shown, the technical scheme adopted in the present invention: a vehicle spoke processing scheme, comprising:

[0018] Step 1, rolling the steel billet into a strip steel with a width of 110-180 mm according to the size of the spokes;

[0019] Step 2, rolling the mandrel in the width direction of the strip into a circle to form a spiral structure;

[0020] Step 3. After the spiral structure is cooled, it is cut longitudinally and unilaterally to make several split ring pieces 1, and the cross section of the cut ring pieces 1 is rectangular;

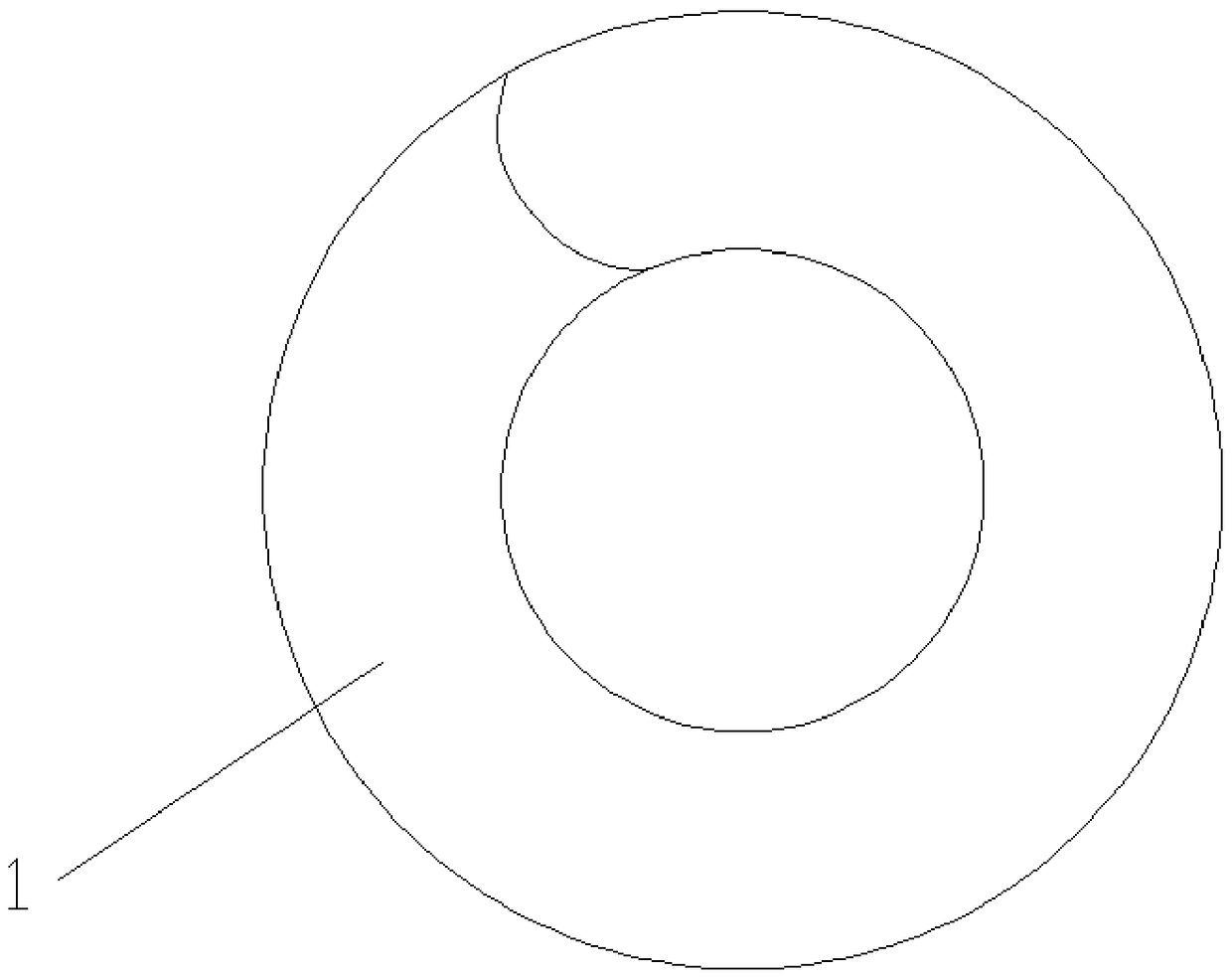

[0021] Step 4. After the split ring is shot blasted and flattened, it is butt-welded along the incision to make a ring piece. The center hole of the ring piece is 2;

[0022] Step 5, leveling the ring piece sequentially, scraping welding slag, rolling the weld seam, grinding the interface burr, punching the bolt hole, spinning or stamping to form the spoke embryo.

[0023] In order to ensure the stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap