Press-fit production line of automobile shock absorbers

A technology for automobile shock absorbers and press-fitting production lines, which is applied in assembly machines, metal processing equipment, sorting and other directions, can solve the problems of reduced production efficiency and high labor intensity of production operators, and achieves high The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

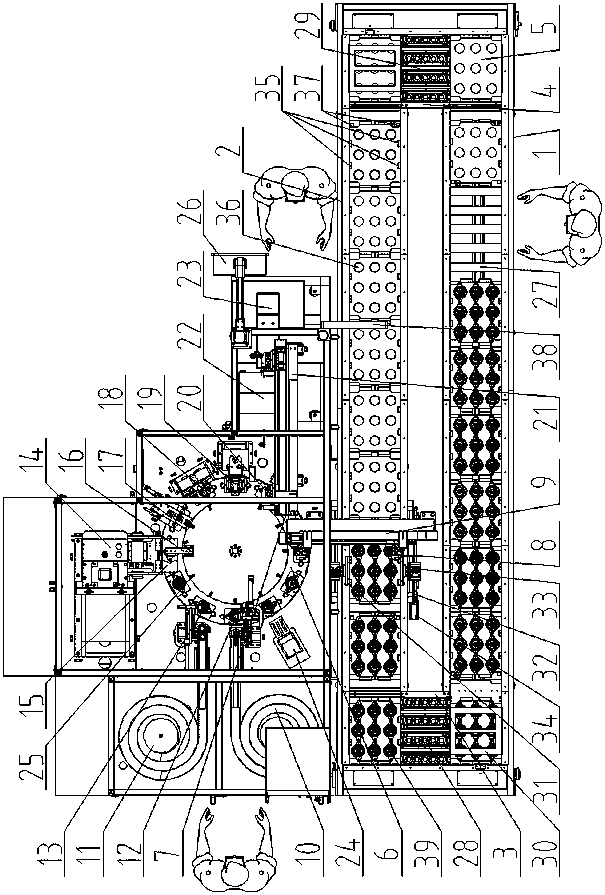

[0033] Such as figure 1It can be seen that the present invention includes a station turntable 6, and the edges of the station turntable 6 are respectively fixed with a plurality of support frame placement blocks 7, and the top surface of the support frame placement block 7 is fixed with a support frame positioning seat 36. The frame placement blocks 7 are evenly distributed on the station turntable 6, and around the station turntable 6, along the rotation direction of the station turntable 6, there are successively a support frame feeding station, an inner liner feeding station, and a cover plate. material station, riveting station, height detection station, torque detection station, through hole detection station and discharge station, when any support frame placement block 7 rotates to the support frame feeding station, all There are corresponding support frames for the inner liner feeding station, cover plate feeding station, riveting station, height detection station, torq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com