Material increasing and decreasing integrated five-axis mixed-machining equipment based on dynamic parameter adjustment and processing method

A technology of dynamic parameters and processing equipment, applied in the direction of additive processing, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of increased processing cycle, clamping positioning deviation, accuracy and surface roughness lower than the corresponding industrial requirements and other issues to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

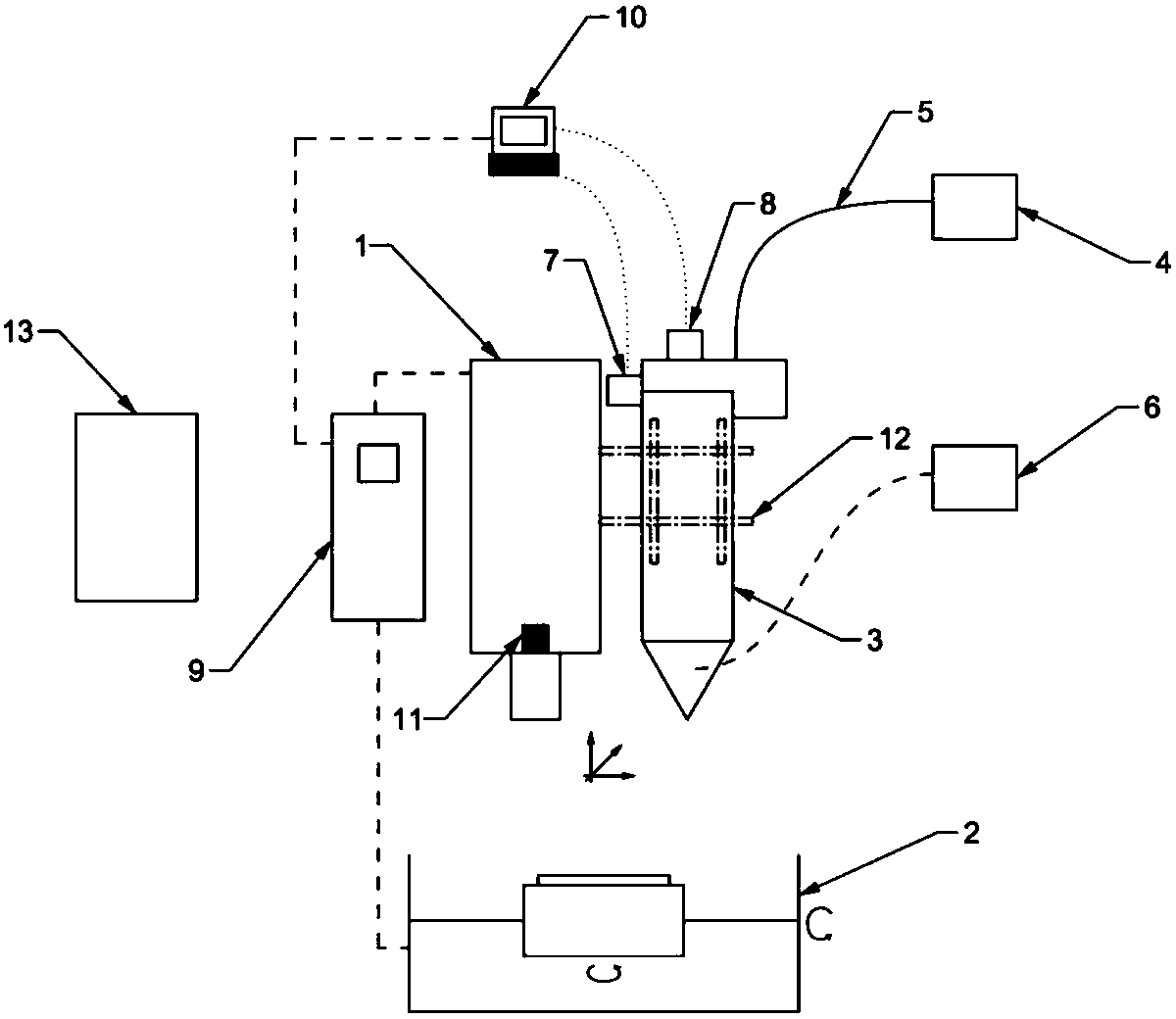

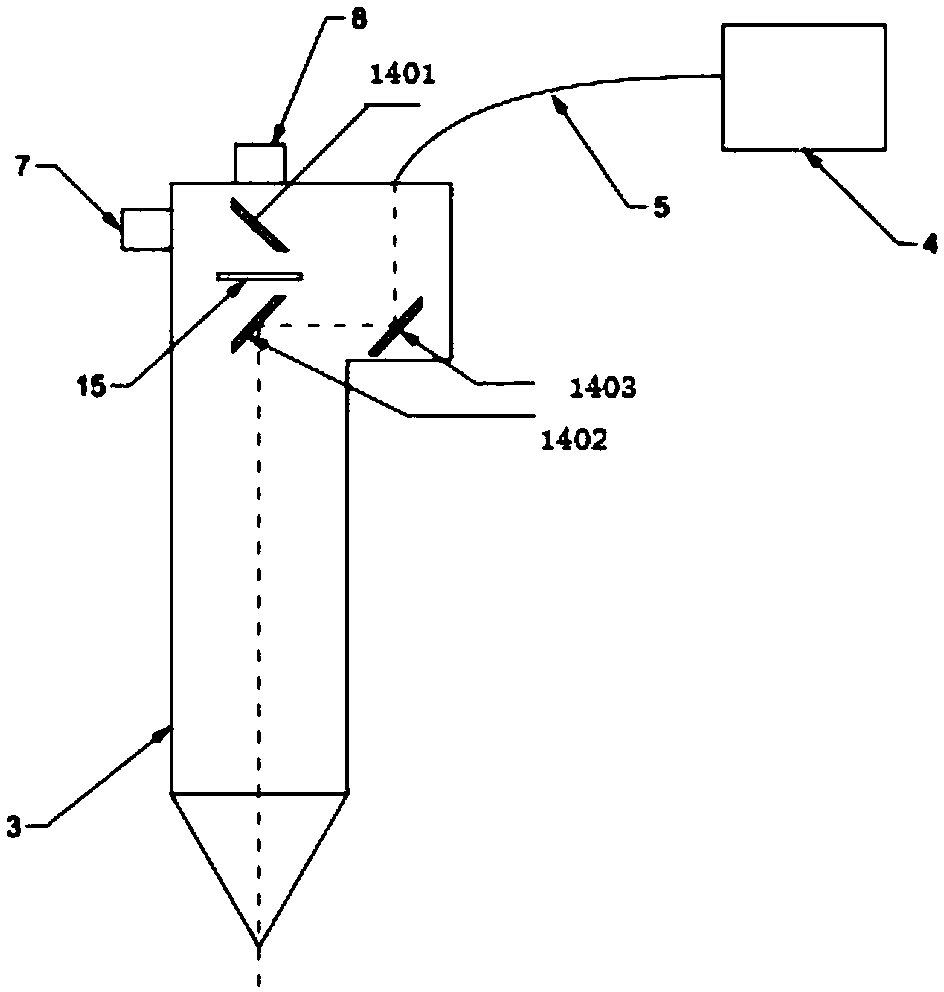

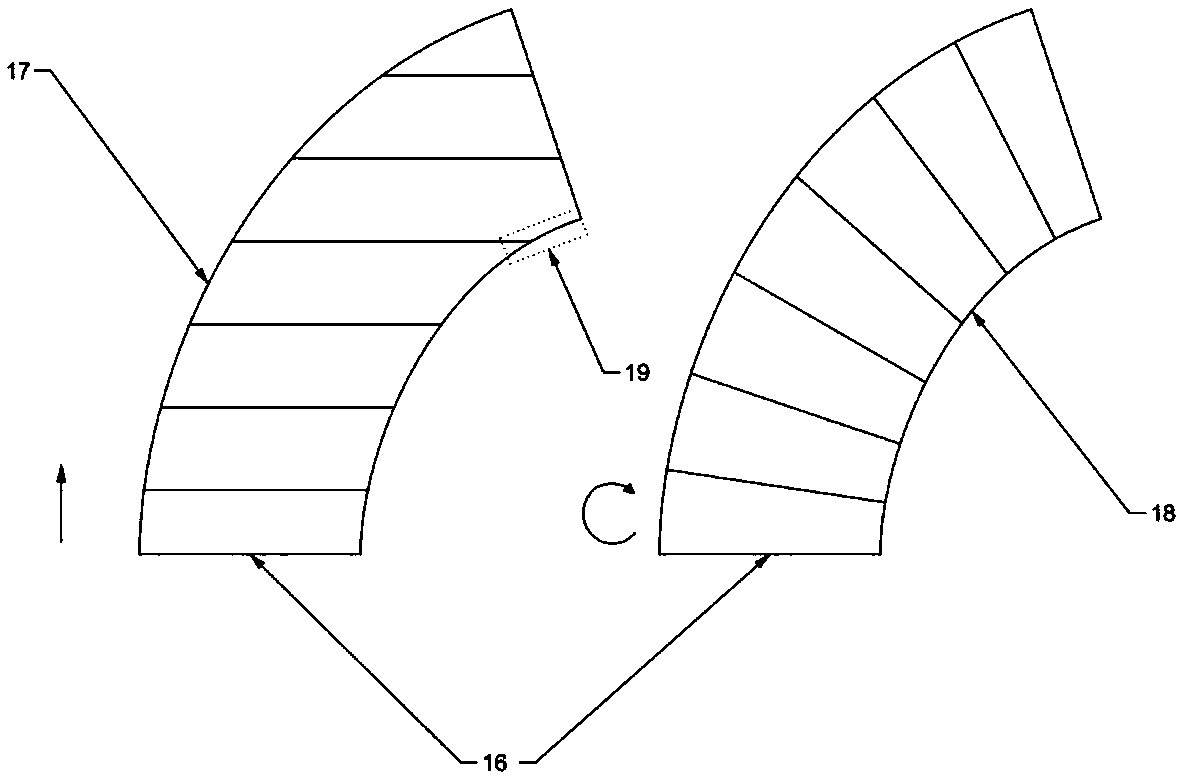

[0036] Combined with the manual Figure 1 with two As shown, a five-axis hybrid processing equipment based on dynamic parameter adjustment, which integrates addition and subtraction of materials, includes a main shaft 1 that can move in the X / Y / Z directions separately, and a shaft that can swing in the A / C directions is installed under the main shaft 1. The turntable 2, the main shaft 1 is connected with a laser nozzle 3 through the pneumatic bracket 12, the ultrasonic tool vibration system 11 is installed on the upper part of the tool of the main shaft 1, the laser distance measuring device 8 is installed on the upper part of the laser nozzle 3, and the CCD camera 7 is installed on the side; The first mirror 1401 inclined to the left, the laser filter 15 and the second mirror 1402 inclined to the right are installed on the top of the interior in sequence from top to bottom, and the third mirror 1403 is symmetrically installed on the right side of the second mirror 1402; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com