Low-energy-consumption precast concrete component steam curing plant building construction method based on solar efficient utilization

A technology of prefabricated concrete and solar energy, applied in the direction of solar thermal energy, solar heat storage, solar collectors, etc., can solve problems that restrict the green development of the concrete product industry, and achieve the goal of reducing steam energy consumption, production costs, and carbon emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

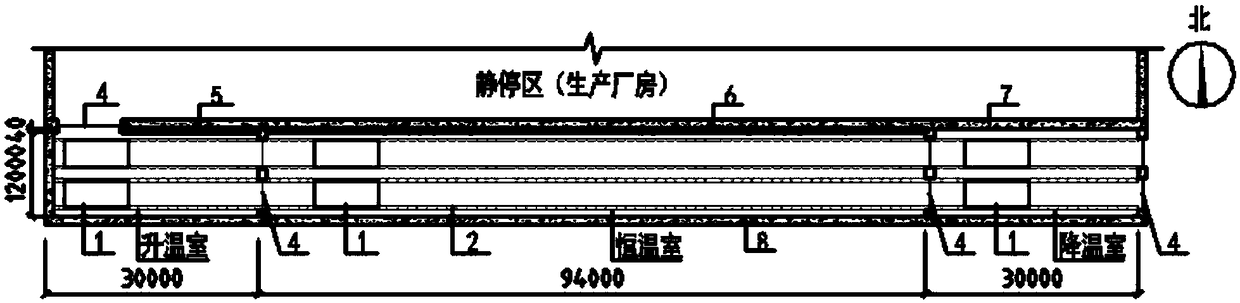

[0019] Combine below Figure 1-3 Taking the maintenance workshop of Lingshou County, Hebei Province as an example, the construction technology of the low-energy consumption precast concrete component steam curing workshop based on the efficient utilization of solar energy of the present invention is described in detail.

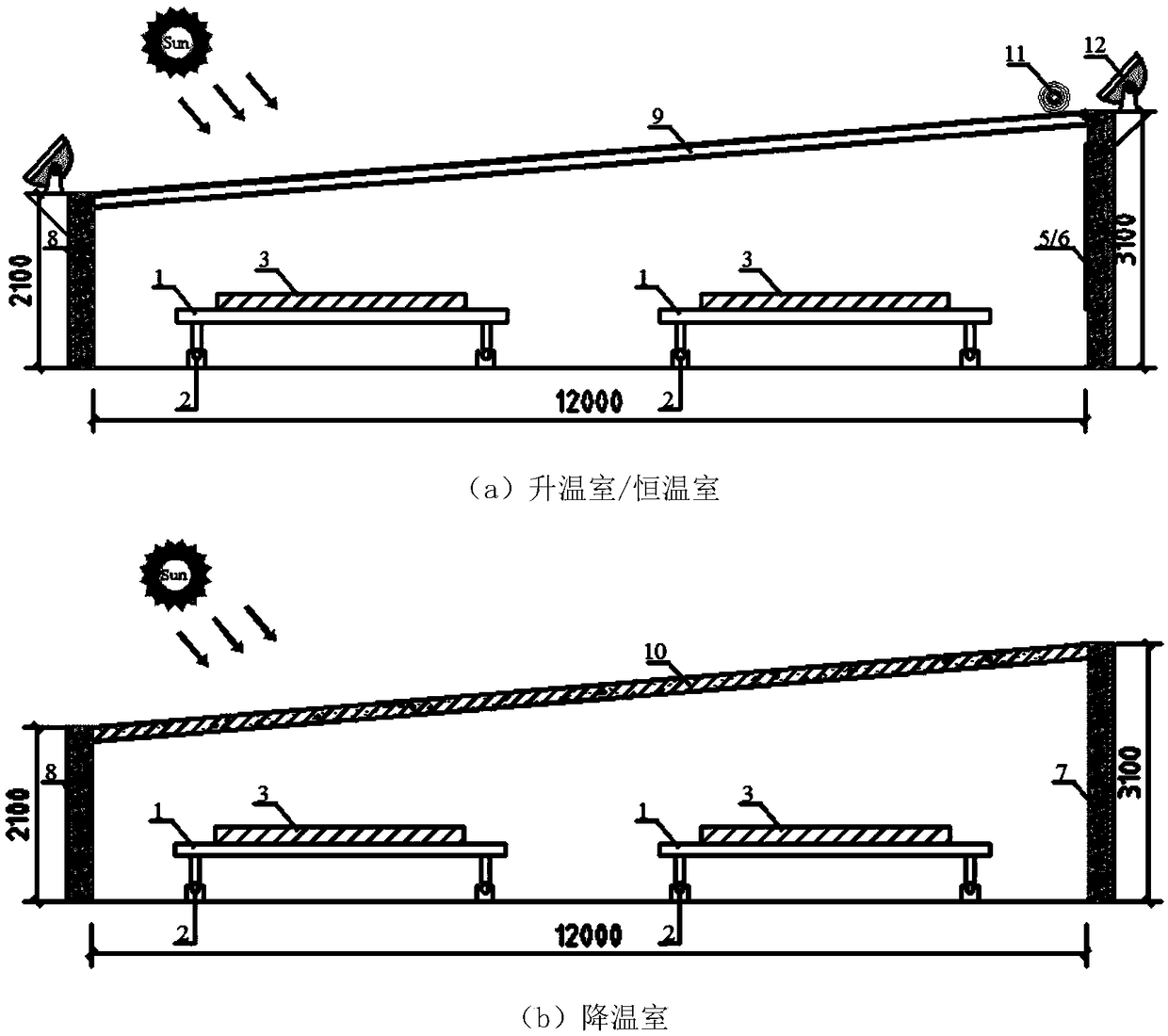

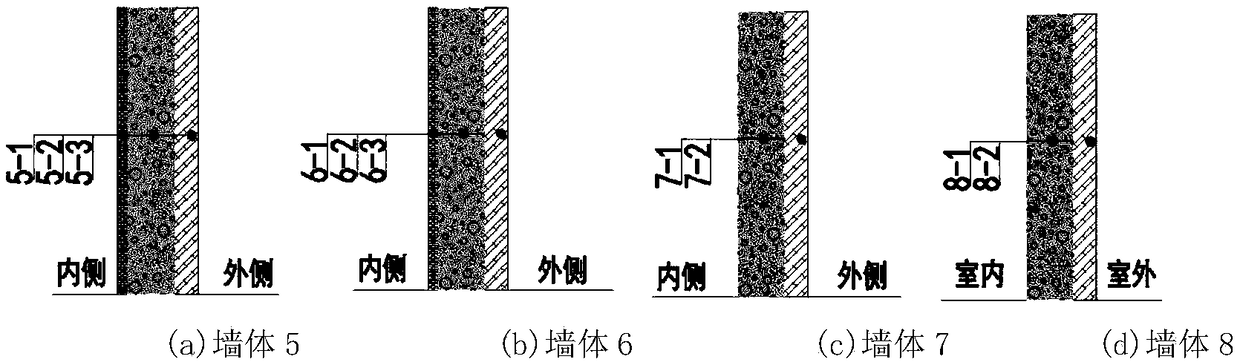

[0020] According to the low-temperature steam curing process, the PC component steam curing workshop building faces south, the static parking area and the production workshop are located on the north side, the south side is the main curing area, and from west to east, there are heating curing workshop, constant temperature curing workshop and cooling curing workshop. workshop.

[0021] From the low-temperature steam curing process, the heating stage usually needs to heat the PC components from normal temperature to 30-40 °C, and maintain it for 2-3 hours; the constant temperature stage needs to continue to heat the PC components from the heating chamber to ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com