Efficient molding plastic mold for wood and plastic wall plate

A technology for wood-plastic wall panels and plastic molds, applied in the field of plastic molds, can solve problems such as slow molding process, and achieve the effects of simple structure, lower temperature, and fast and efficient molding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

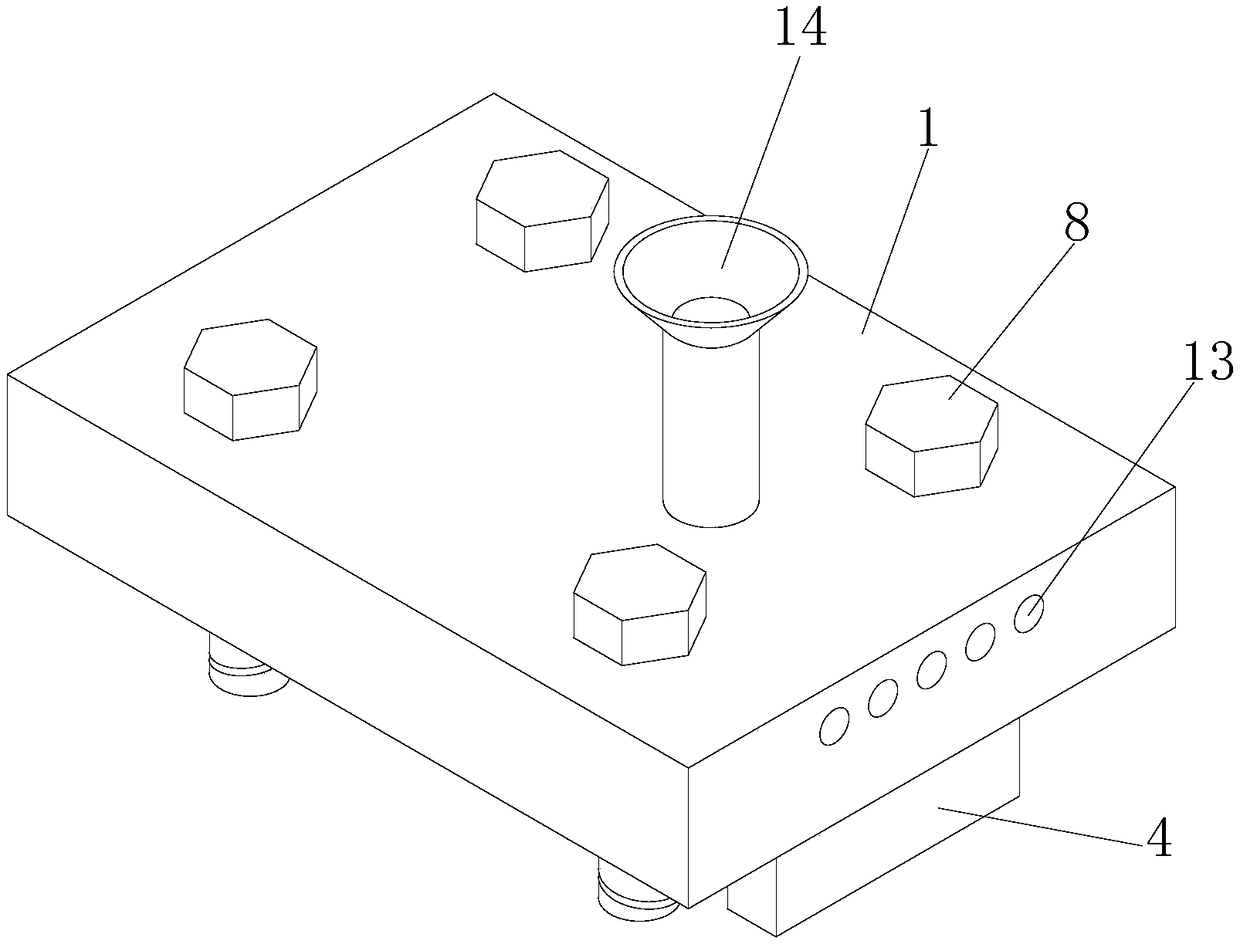

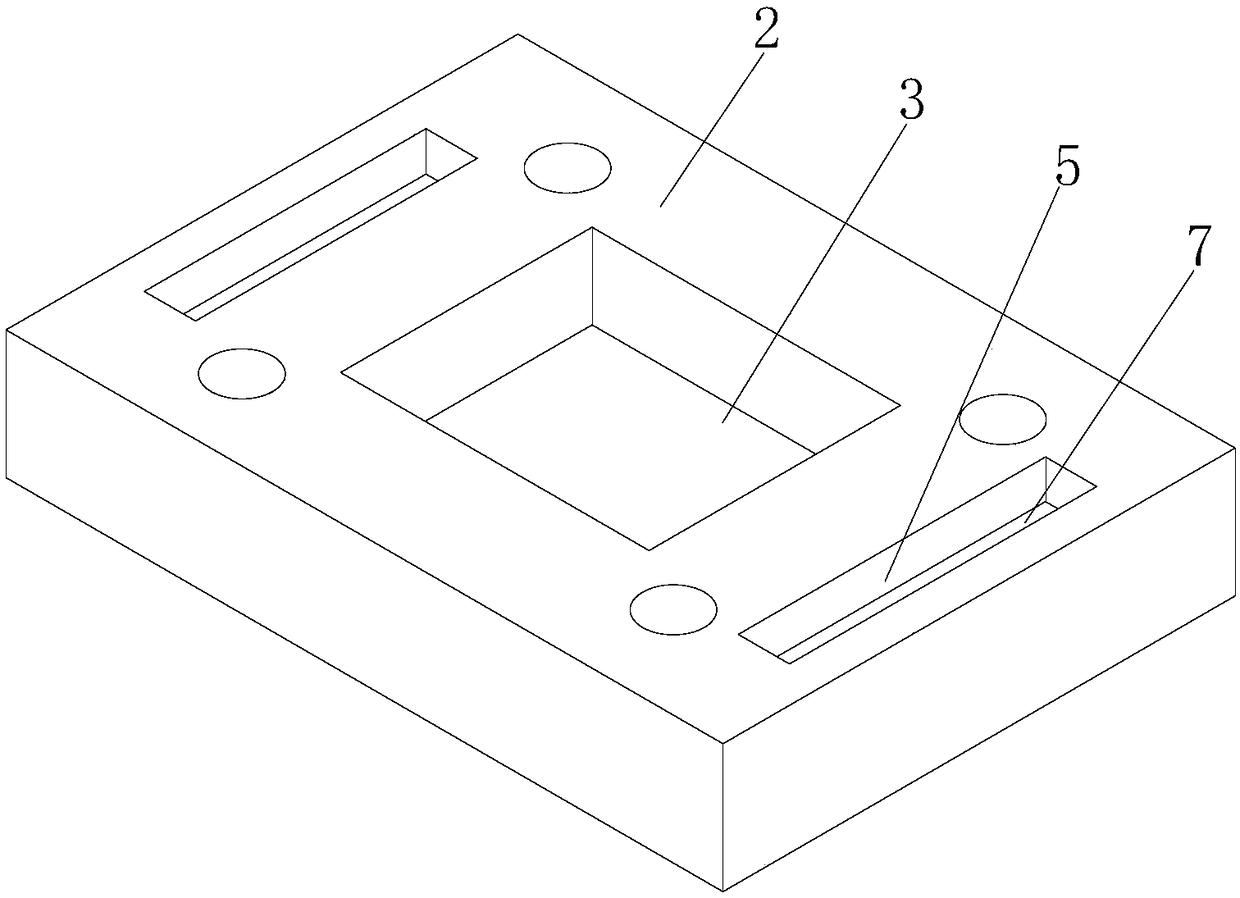

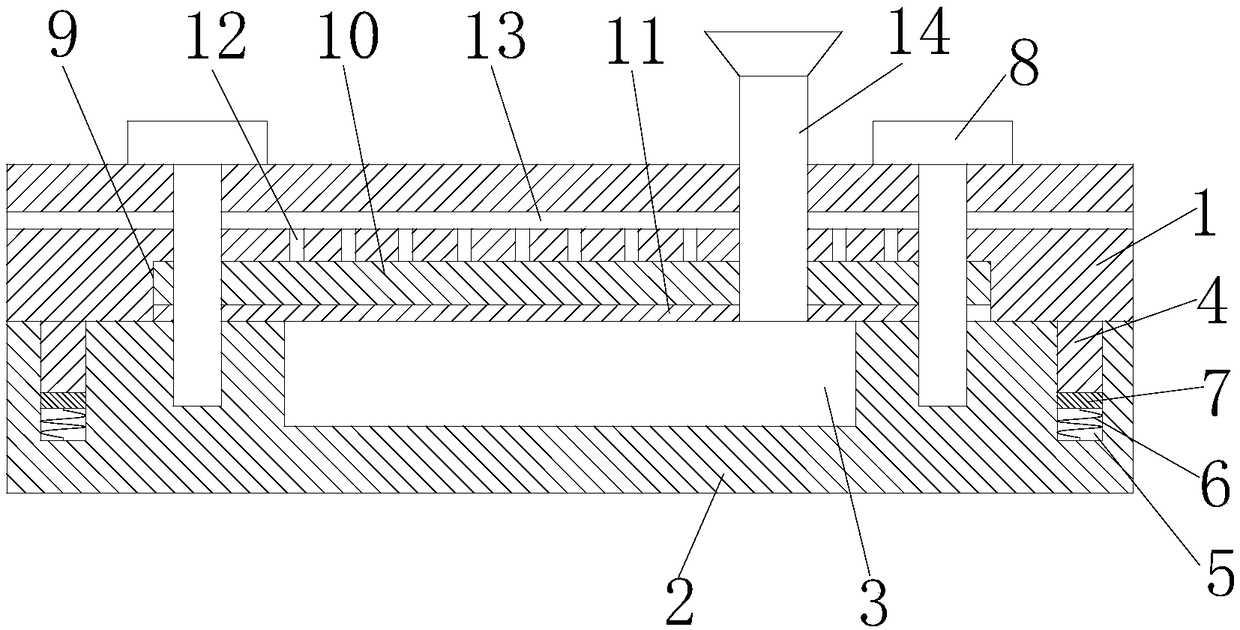

[0017] Reference Figure 1-3 , A high-efficiency molding plastic mold for wood-plastic wallboards, comprising an upper mold 1, the upper mold 1 is fixedly connected with a lower mold 2 by bolts 8, and the middle position of the upper surface of the lower mold 2 is provided with an injection groove 3 and an upper mold 1. Both sides of the lower surface are fixedly connected to the limit plate 4. The function of the limit plate 4 is to enable the upper mold 1 to be accurately fixed on the lower mold 2. The upper mold 1 and the limit plate 4 are integrated, and the lower mold 2 is located on One side of each limit plate 4 is provided with a li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap