Battleship protective tank based on pressure relief and subdivision functions

A technology of protective liquid and compartmentalization, applied in ships, defense equipment, ship weapons, etc., can solve the problems of difficulty in resisting multiple blows, loss of watertightness, tank damage, etc., to save ship space, improve protection, The effect of improving the protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

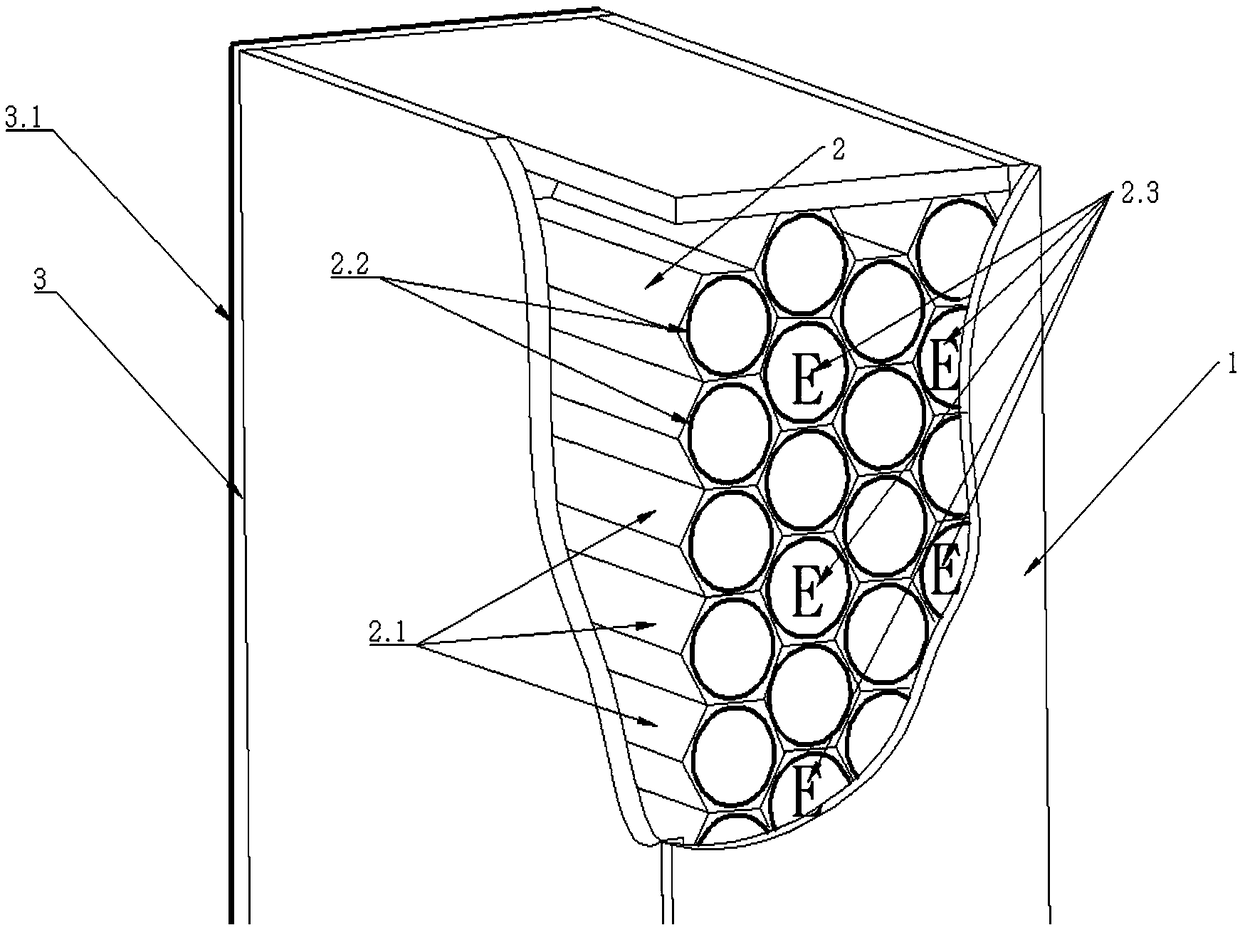

[0020] The invention provides a battleship protective liquid tank based on decompression and subdivision functions, such as figure 1 As shown, the cabin body 2 surrounded by the tank front panel 1, the tank rear panel 3, and the tank side panels is composed of a tubular sub-cabin structure 2.1 with a regular hexagonal cross-section. The adjacent subdivision structures 2.1 are tightly connected so that the section is honeycomb-shaped, and the side walls of the subdivision structures 2.1 are perpendicular to the side panels of the tank, and are densely paved in the entire cabin body 2; every six circumferentially connected subdivision structures 2.1 are provided with A liquid-free empty cabin 2.3 The empty cabin plays the role of pressure relief and expansion reduction, which can immerse the expanded liquid after being hit by high-speed fragments, relie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com