Plastic film reel erecting device with pipe core

A plastic film and erecting device technology, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of increasing labor intensity, occupying a large area, and laborious cutting, so as to reduce work intensity and make The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

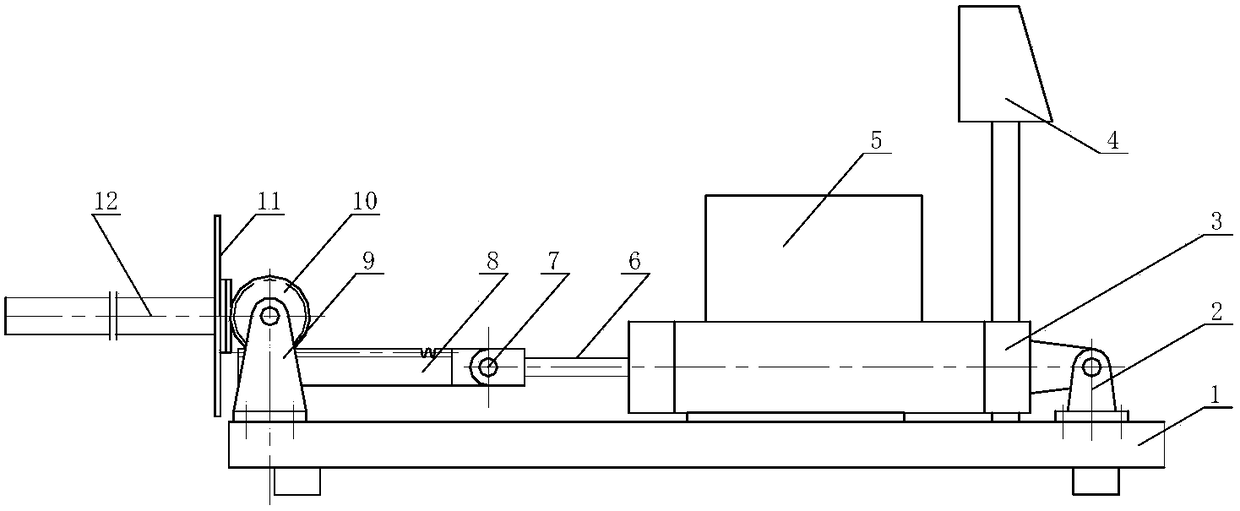

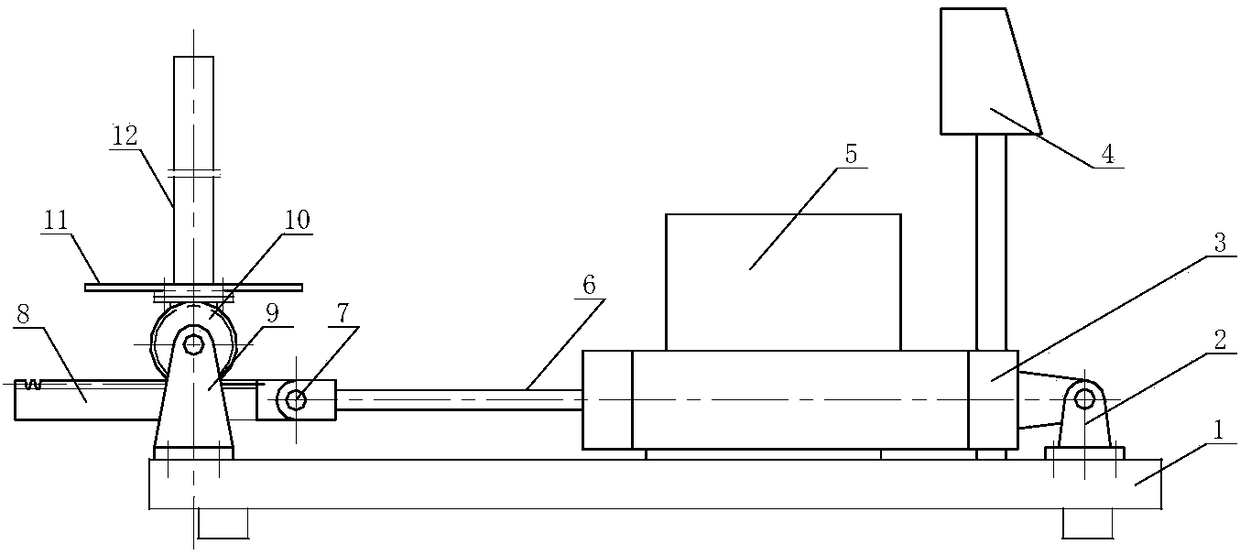

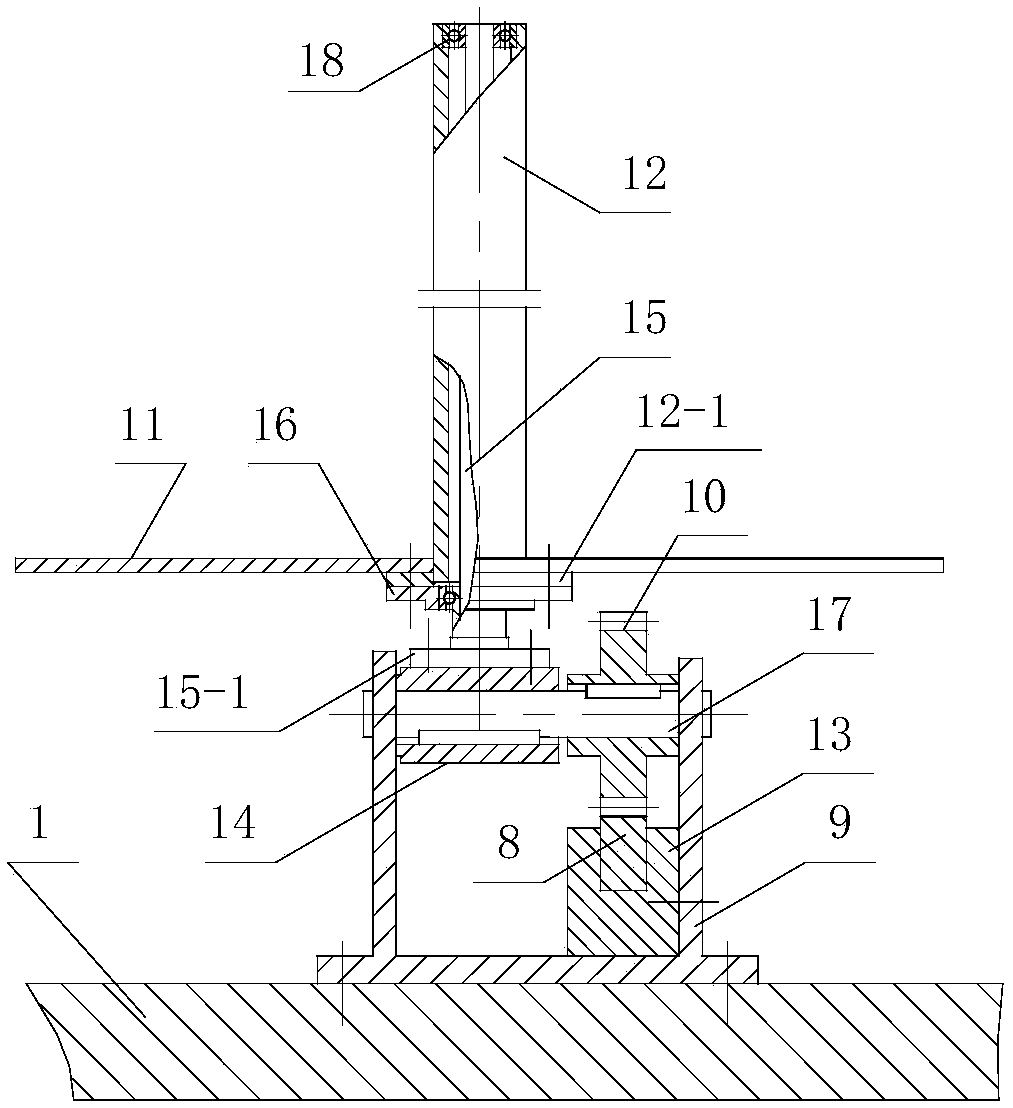

[0016] Example 1, see Figure 1-Figure 3 , a device for erecting plastic film rolls with a tube core, including a base 1 on which an electric control box 4, a hydraulic mechanism 5, an oil cylinder 3, an overturning mechanism and a transmission mechanism are arranged, and the piston of the oil cylinder The rod 6 is connected with a transmission mechanism for driving the turning mechanism to turn over through the hinge 7, and the electric control box 4 is electrically connected with the hydraulic mechanism.

[0017] In this embodiment, the hinge 7 is preferably a flexible joint.

[0018] In this embodiment, the transmission mechanism includes a rack 8 connected to the piston rod of the oil cylinder, a gear bracket 9, a gear 10 and a shaft 7, the gear bracket is fixed on the base 1, and the rack is fixed on the gear The rack seat 13 on the inside of the bracket is affixed and meshed with the gear mounted on the gear bracket. Described axle 7 is installed on the gear bracket, a...

Embodiment 2

[0020] Example 2, see Figure 4 , a device for erecting plastic film rolls with tube cores, including a base 1 on which an electric control box 4, a hydraulic mechanism 5, three oil cylinders 3, three turning mechanisms and three transmission mechanisms are arranged, and the pistons of the oil cylinders The rod 6 is connected with a transmission mechanism for driving the turning mechanism to turn over through the hinge 7, and the electric control box 4 is electrically connected with the hydraulic mechanism. Both the turning mechanism and the transmission mechanism are the same as those in the embodiment, and the hydraulic mechanism needs to control each oil cylinder separately.

[0021] The erecting device of the plastic film roll with tube core is not limited to the single oil cylinder or three oil cylinders and the corresponding turning mechanism and transmission mechanism described in Embodiment 1 and Embodiment 2, but also can arbitrarily set the position of the oil cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com