Honeycomb board structure and storage tank buoyancy chamber structure

A technology of honeycomb panels and honeycomb cores, applied in the field of petrochemical storage tanks, can solve the problems of large oil and gas space, economic loss, and large volatilization, and achieve the effects of improving construction efficiency, reliable structural strength, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

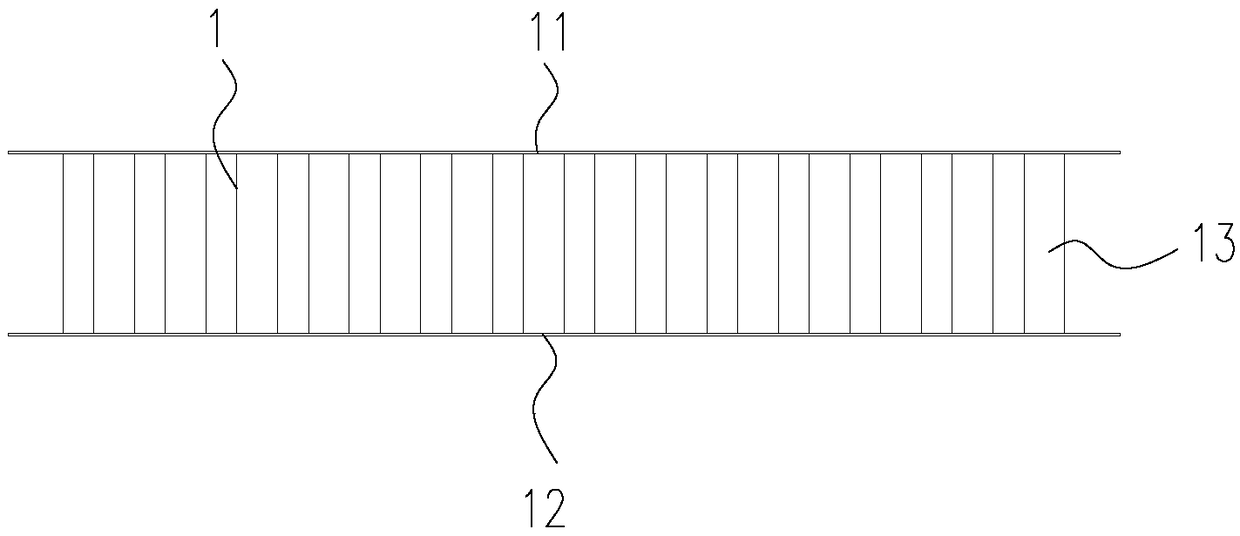

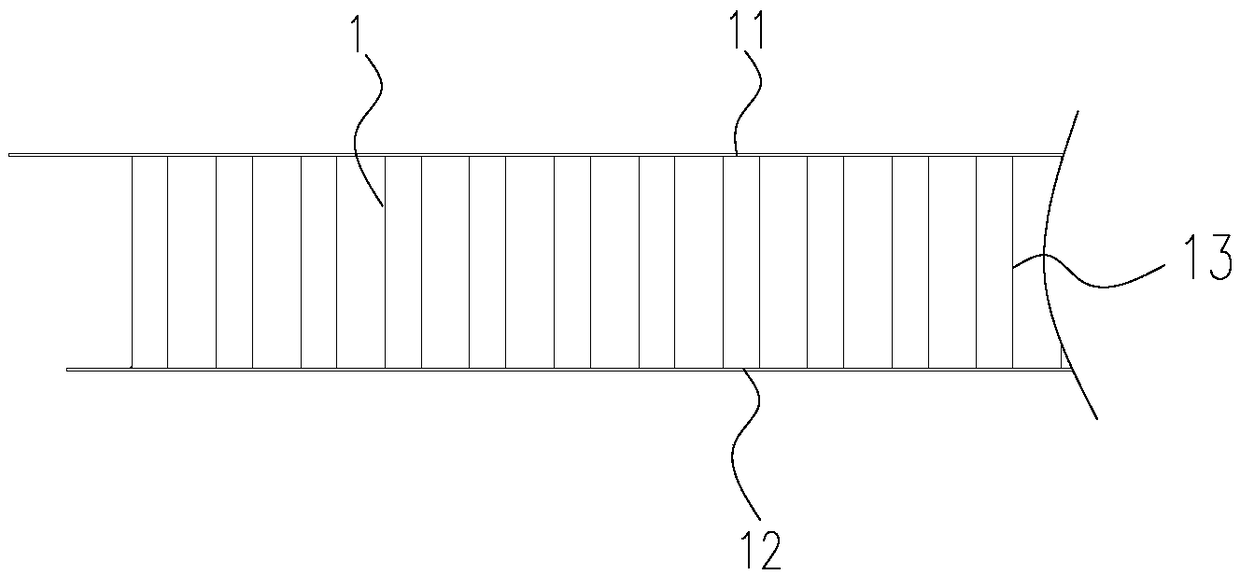

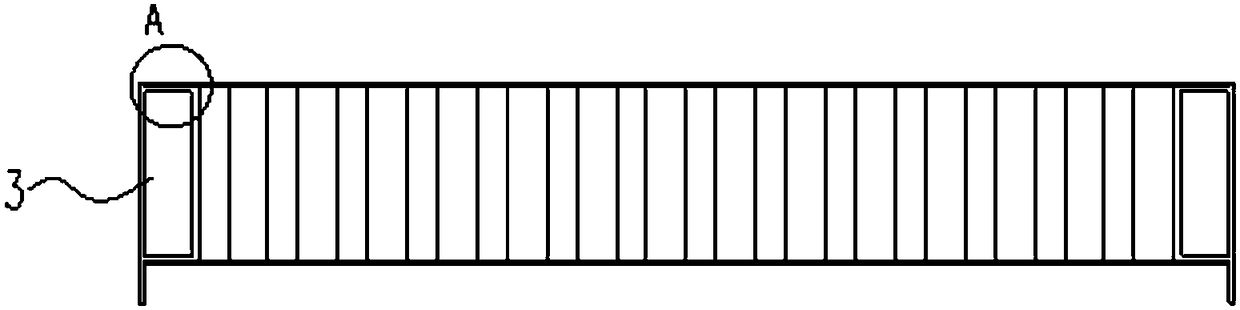

[0037] see Figure 1~6 The honeycomb panel structure shown includes a honeycomb panel main body 1, a first edge-sealing structure 2 and a second edge-sealing structure 3; The two sides are connected, and the two second edge sealing structures 3 are respectively connected to the other two sides of the honeycomb panel main body 1; wherein, the first edge sealing structure 2 is provided with a first convex edge 21 parallel to the extending direction of the honeycomb panel main body 1. The first convex edge 21 is used to realize the connection and fixation of the honeycomb panel structure in the direction perpendicular to the extending direction of the panel surface, and the second edge sealing structure 3 is provided with a second convex edge 31 perpendicular to the extending direction of the panel surface of the honeycomb panel main body 1, The second convex edge 31 is used to realize the connection and fixation of the honeycomb panel structure in a direction parallel to the ext...

Embodiment 2

[0042] see Figure 1~6The honeycomb panel structure shown includes a honeycomb panel main body 1, a first edge-sealing structure 2 and a second edge-sealing structure 3; The two sides are connected, and the two second edge sealing structures 3 are respectively connected to the other two sides of the honeycomb panel main body 1; wherein, the first edge sealing structure 2 is provided with a first convex edge 21 parallel to the extending direction of the honeycomb panel main body 1. The first convex edge 21 is used to realize the connection and fixation of the honeycomb panel structure in the direction perpendicular to the extending direction of the panel surface, and the second edge sealing structure 3 is provided with a second convex edge 31 perpendicular to the extending direction of the panel surface of the honeycomb panel main body 1, The second protruding edge 31 is used to realize the connection and fixation of the honeycomb panel structure in a direction parallel to the ...

Embodiment 3

[0046] A storage tank floating structure, such as Figure 9 with 10 As shown, it includes a honeycomb panel structure and a main beam 4 for fixing the honeycomb panel structure; wherein, the honeycomb panel structure includes a honeycomb panel main body 1, a first edge sealing structure 2 and a second edge sealing structure 3; the honeycomb panel main body 1 is arranged in a rectangular shape, the two first edge-sealing structures 2 are respectively connected to the opposite sides of the honeycomb panel main body 1, and the two second edge-sealing structures 3 are respectively connected to the other two sides of the honeycomb panel main body 1; wherein, the first edge-sealing structure 2 is provided with a first convex edge 21 parallel to the extending direction of the honeycomb panel main body 1. The first convex edge 21 is used to realize the connection and fixation of the honeycomb panel structure in the direction perpendicular to the extending direction of the panel surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com