Device and method for in-situ preparation of refractory metal carbide nanowires/tubes by template method and thermal evaporation technology

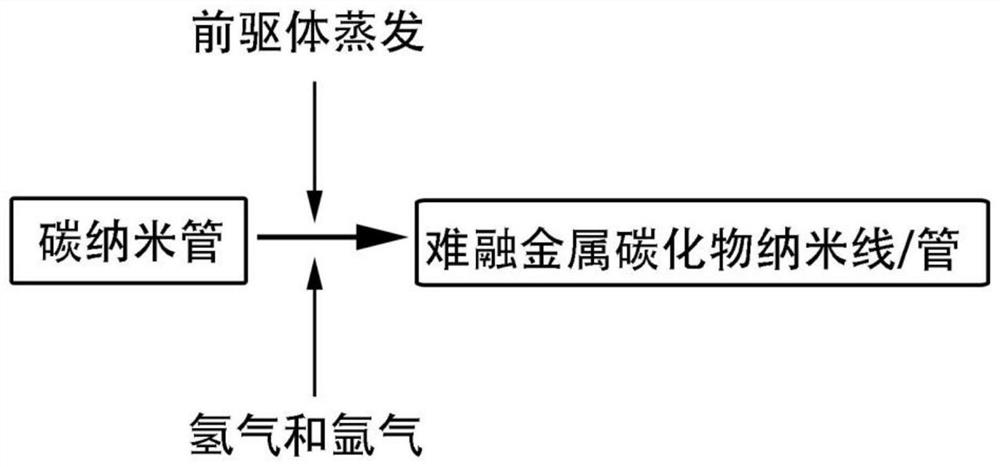

A technology for in-situ preparation of refractory metals, applied in the fields of carbon compounds, chemical instruments and methods, nanotechnology, etc., can solve the problems of complex chemical composition, damage to matrix materials, corrosion, etc., to achieve simple preparation, reduce difficulty, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

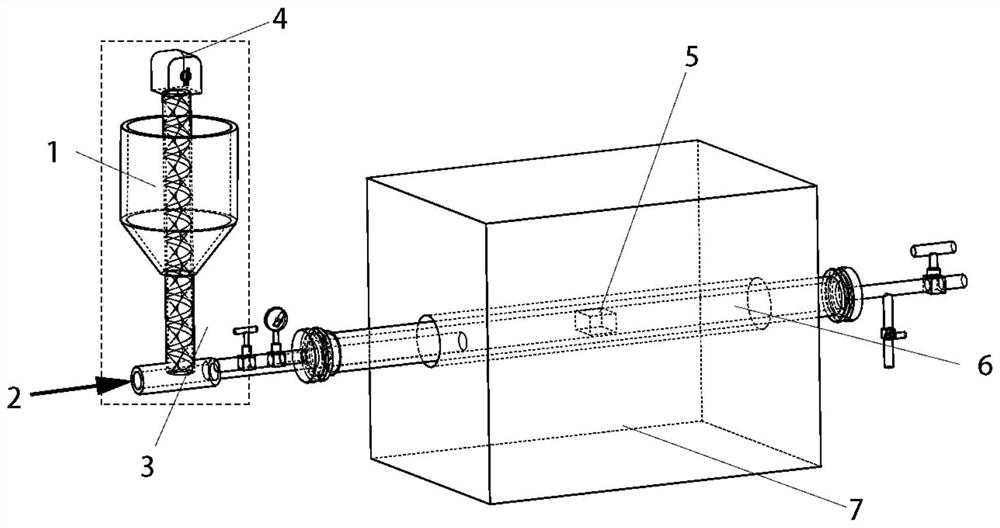

[0029] Step 1: Place the CNT in the corundum tube in the constant temperature zone of the horizontal CVD furnace, plug the tube plugs on both sides and fix the flange with clamps; the tube plugs have through holes;

[0030] Step 2: Open the vacuum pump valve and start the vacuum pump, pump the furnace chamber to negative pressure, and close the vacuum valve. If the pressure of the furnace chamber changes for a long time, it means that the airtightness is good, and proceed to the next step; Check the sealing ring;

[0031] Step 3: Open the valve of the carrier gas pipe 2, feed inert gas and hydrogen, adjust the pressure value of the furnace chamber to normal pressure, and open the tail gas valve; at the same time, start the powder feeder 4 to pass the refractory metal carbide precursor through The powder container 1 enters the corundum tube of the horizontal CVD furnace along with the inert gas;

[0032] The inert gas is argon or nitrogen;

[0033] The flow of the inert gas i...

Embodiment 2

[0037] Step 1: Place the CNT in the corundum tube in the constant temperature zone of the horizontal CVD furnace, plug the tube plugs on both sides and fix the flange with clamps; the tube plugs have through holes;

[0038] Step 2: Open the vacuum pump valve and start the vacuum pump, pump the furnace chamber to negative pressure, and close the vacuum valve. If the pressure of the furnace chamber changes for a long time, it means that the airtightness is good, and proceed to the next step; Check the sealing ring;

[0039] Step 3: Open the valve of the carrier gas pipe 2, feed inert gas and hydrogen, adjust the pressure value of the furnace chamber to normal pressure, and open the tail gas valve; at the same time, start the powder feeder 4 to pass the refractory metal carbide precursor through The powder container 1 enters the corundum tube of the horizontal CVD furnace along with the inert gas;

[0040] The inert gas is argon or nitrogen;

[0041] The flow of the inert gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com