A kind of preparation method of high-purity zinc sulfate monohydrate

A technology of zinc sulfate and zinc sulfate solution, applied in zinc sulfate and other directions, can solve problems such as corrosion of pipelines and concentration kettles, and achieve the effect of solving easy corrosion of pipelines and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

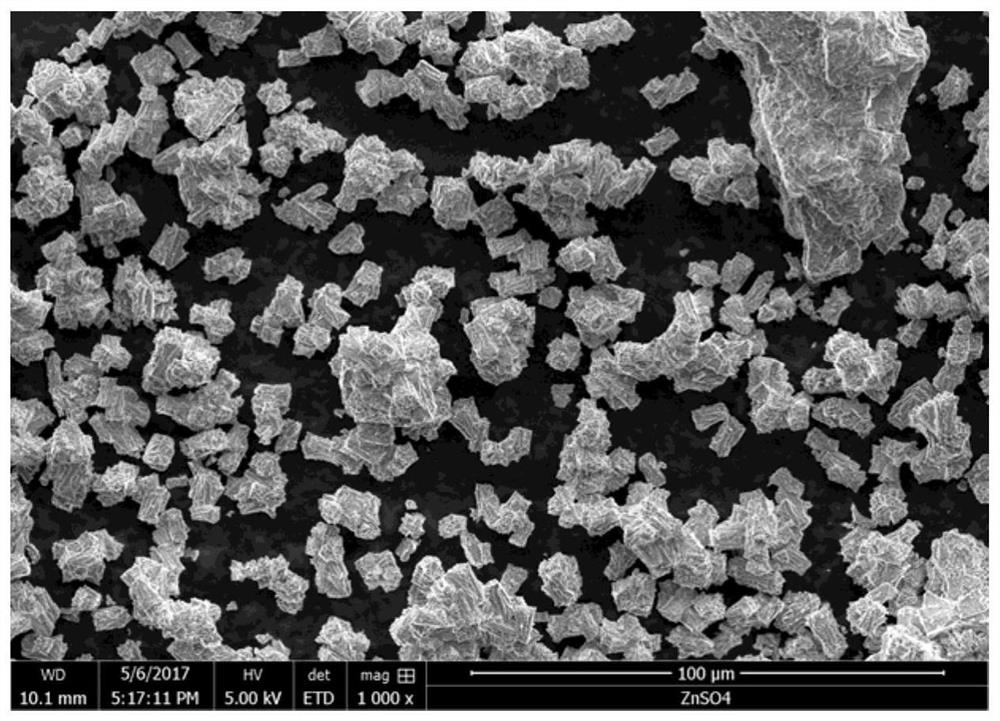

Image

Examples

Embodiment 1

[0046] Step 1, zinc sulfate solution and pH adjustment solution are added to reaction still, and pH adjustment solution is 10mol / L liquid caustic soda, adjust pH to 9.0, make the Zn in the solution 2+ Precipitate as Zn(OH) 2 After reacting for 30 minutes, pass through the filter press to obtain the zinc hydroxide filter residue, use pure water to slurry the zinc hydroxide filter residue, and pump it into the washing kettle, add pure water to fill the washing kettle, heat up to 50 ° C and stir for 30 minutes and After filtering and repeating the washing operation twice, a high-purity filter residue is obtained, and the Na in the filter residue is detected + The content of Na in the high-purity filter residue + The content is 0.08wt.%, using zinc sulfate solution to re-slurry the high-purity filter residue to obtain zinc hydroxide slurry;

[0047] Step 2, adding the zinc sulfate solution to the callback kettle, opening the steam valve, adjusting the reaction temperature to 50°...

Embodiment 2

[0052] Step 1, zinc sulfate solution and pH adjustment solution are added to reactor and reacted, pH adjustment solution is 8mol / L liquid caustic soda, adjust pH to 9.5, make the Zn in the solution 2+ Precipitate as Zn(OH) 2 After reacting for 40 minutes, pass through the filter press to obtain the zinc hydroxide filter residue, use pure water to slurry the zinc hydroxide filter residue, and pump it into the washing kettle, add pure water to fill the washing kettle, heat up to 40 ° C and stir for 60 minutes and After filtering and repeating the washing operation twice, a high-purity filter residue is obtained, and the Na in the filter residue is detected + The content of Na in the high-purity filter residue + The content is 0.06wt.%, using zinc sulfate solution to re-slurry the high-purity filter residue to obtain zinc hydroxide slurry;

[0053] Step 2, adding the zinc sulfate solution to the callback kettle, opening the steam valve, adjusting the reaction temperature to 40°...

Embodiment 3

[0057] Step 1, zinc sulfate solution and pH adjustment solution are added to reactor and reacted, pH adjustment solution is 5mol / L liquid caustic soda, adjust pH to 9.3, make the Zn in the solution 2+ Precipitate as Zn(OH) 2 After reacting for 30 minutes, pass through the filter press to obtain the zinc hydroxide filter residue, use pure water to slurry the zinc hydroxide filter residue, and pump it into the washing kettle, add pure water to fill the washing kettle, raise the temperature to 45 ° C and stir for 60 minutes and After filtering and repeating the washing operation twice, a high-purity filter residue is obtained, and the Na in the filter residue is detected + The content of Na in the high-purity filter residue + The content is 0.09wt.%, using zinc sulfate solution to re-slurry the high-purity filter residue to obtain zinc hydroxide slurry;

[0058] Step 2, adding the zinc sulfate solution to the reaction kettle, opening the steam valve, adjusting the reaction temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com