Efficient integrated tar residue discharging system

A technology for integrating tar and tar slag, which is applied in coking ovens, petroleum industry, and coking ovens with mechanical equipment transportation, etc., can solve problems such as high labor intensity, affecting the working environment, and environmental pollution, so as to improve slag discharge efficiency and reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

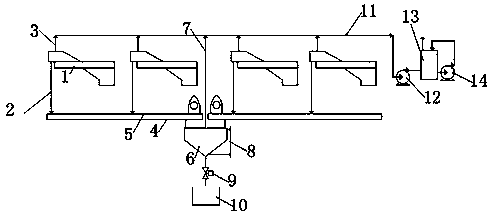

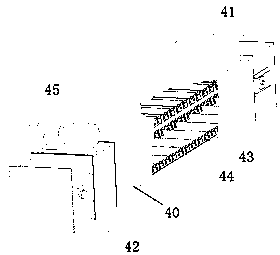

[0016] Refer to attached figure 1 , 2 , a high-efficiency integrated tar slag discharge system, including a slag scraper 1, a slag discharge pipe 2, a slag scraper discharge pipe 3, a slag scraper 4, a closed tar slag silo 6, a slag silo release pipe 7, a liquid Position meter 8, electric slag discharge valve 9, tar slag cleaning bucket 10, exhaust gas pipeline 11, exhaust gas induced draft fan 12 and oil washing tower 13, multiple slag scraping tanks 1 through slag scraper 4 and closed tar slag silo 6 Correspondingly, a tar slag cleaning bucket 10 is provided, the slag scraping tank 1 is provided with a slag discharge pipe 2 and a slag scraping tank discharge pipe 3, and the slag scraping machine 4 includes a casing 40, a material inlet 41, and a material discharge port 42 , a chain 43, a scraper 44 and a motor 45, the top of the casing 40 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com