Warp beam dyeing machine reversing device

A technology of a commutator device and a dyeing machine is applied in the field of dyeing machinery, which can solve the problems of increasing power consumption, increasing pump power, and increasing costs, and achieves the effects of saving energy consumption, reducing pump power, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

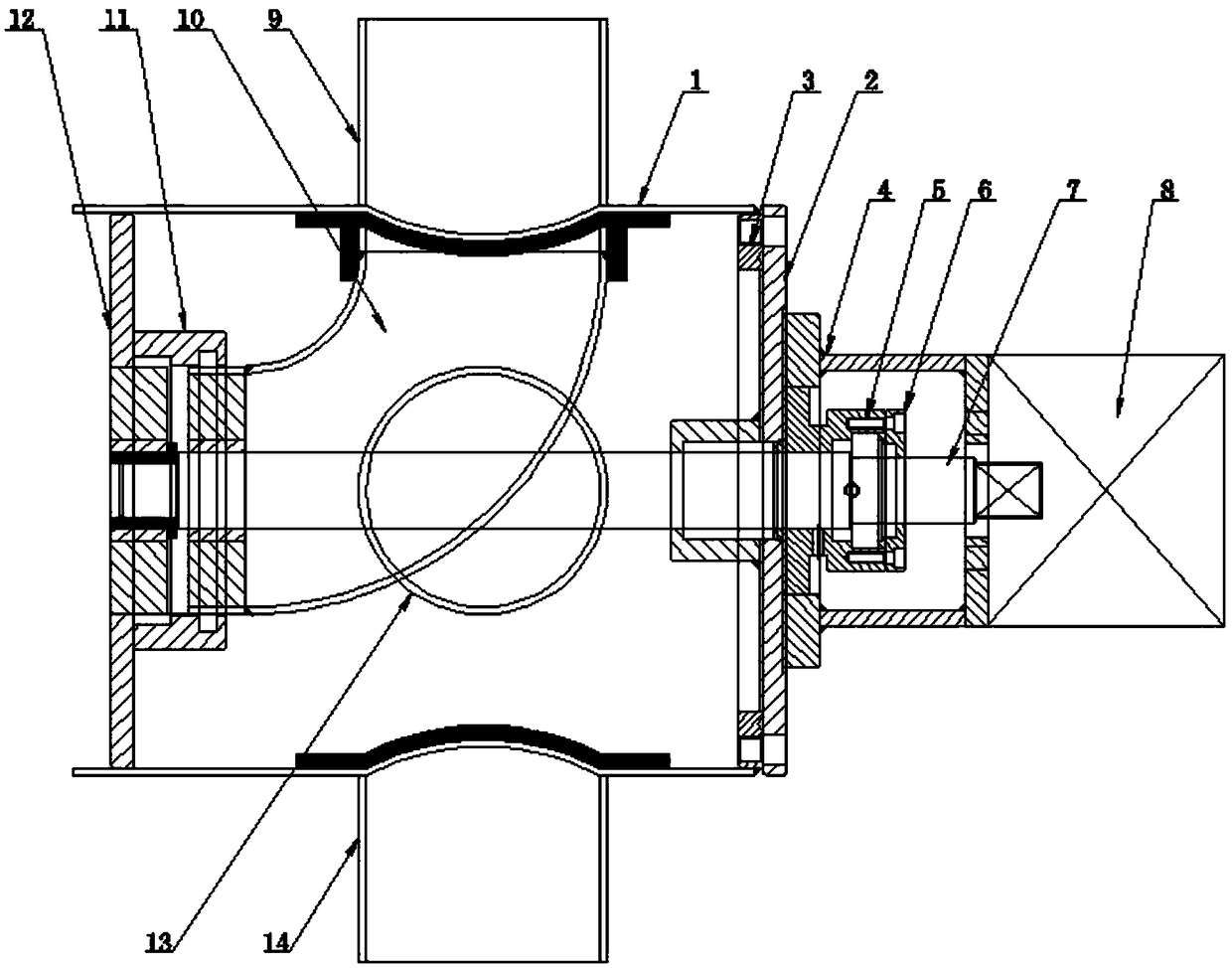

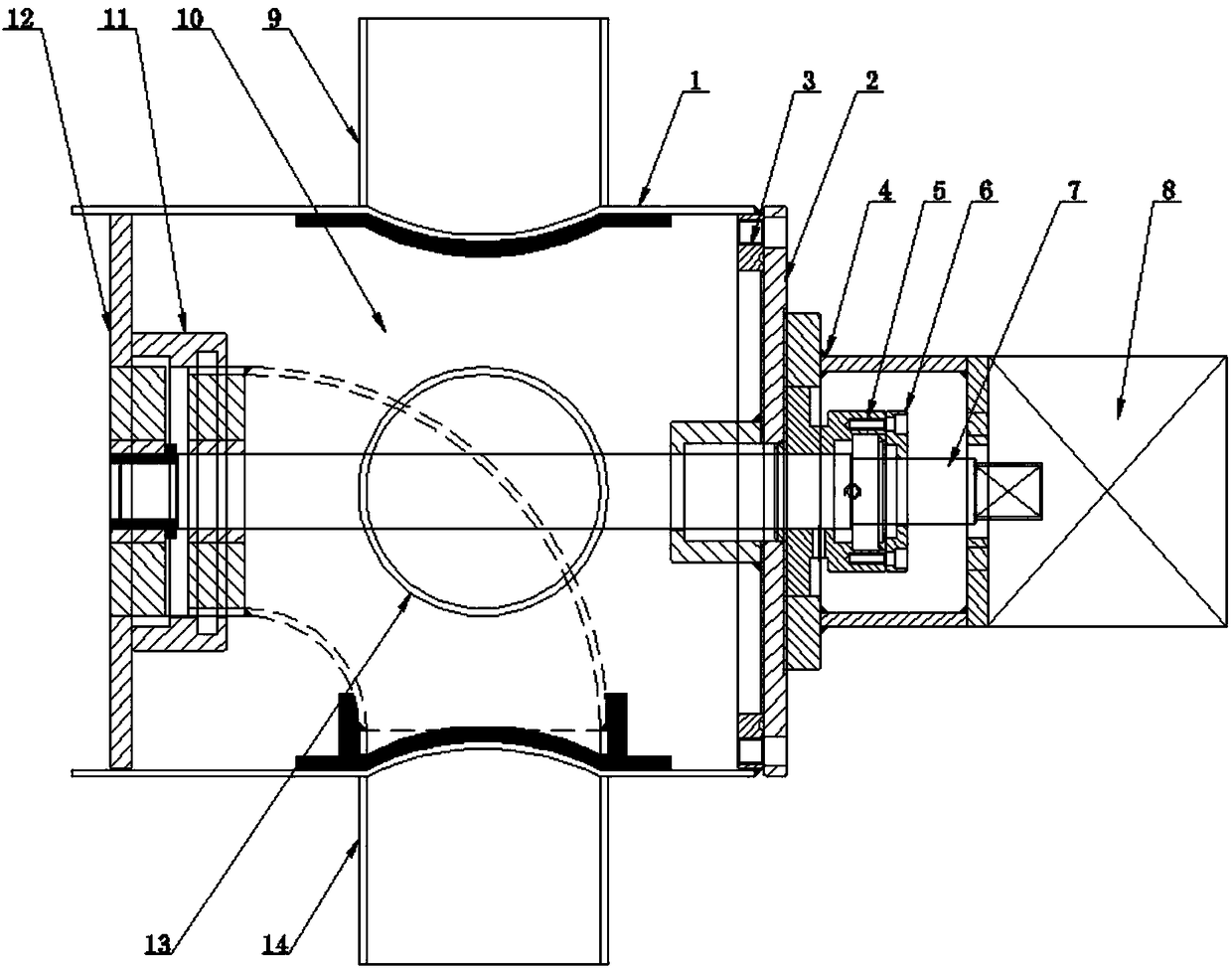

[0018] Embodiment 2: as figure 2 As shown, a reversing device for a warp beam dyeing machine of the present invention includes a reversing device cylinder 1, and the reversing device cylinder 1 includes a flow regulating device cover plate 2, an actuator base 4, a flow regulating sealing device 5, Flow regulation and reversing shaft 7, actuator 8, pump injection port 9, flow regulation elbow 10, flow regulation fixed flange 12, flow regulation suction port 13 and pump suction port 14, the flow regulation device cover plate 2 Set at one end of the reversing device cylinder 1; the actuator base 4 is set on the cover plate 2 of the flow regulating device; the flow regulating sealing device 5 is set inside the actuator base 4; the flow regulating and reversing shaft 7 is horizontally Through the cylinder body 1 of the reversing device; the actuator 8 is arranged on the actuator base 4; the pump injection port 9 is arranged at the upper opening of the cylinder body 1 of the revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com