Device and method for recycling of water vapor in drying system of paper pulp molded products and improvement of drying efficiency of drying system at same time

A pulp molding and drying system technology, applied in textiles and papermaking, etc., can solve problems such as waste of water resources, and achieve the effects of saving water resources, good drying effect, and reducing humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

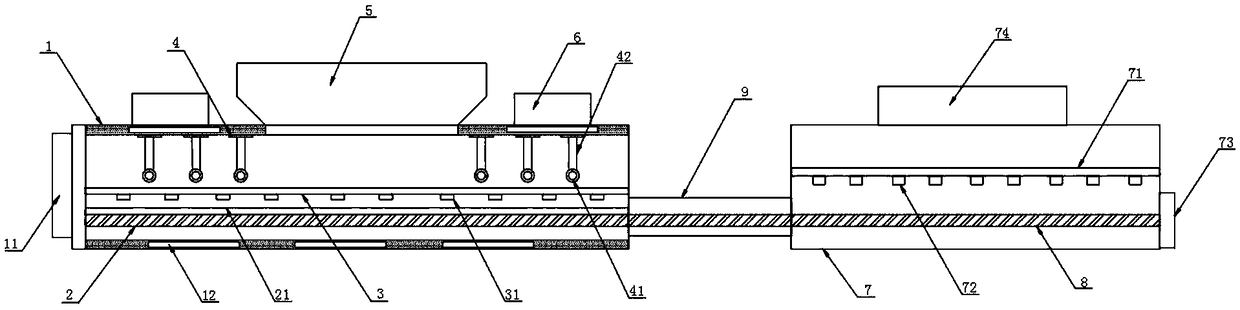

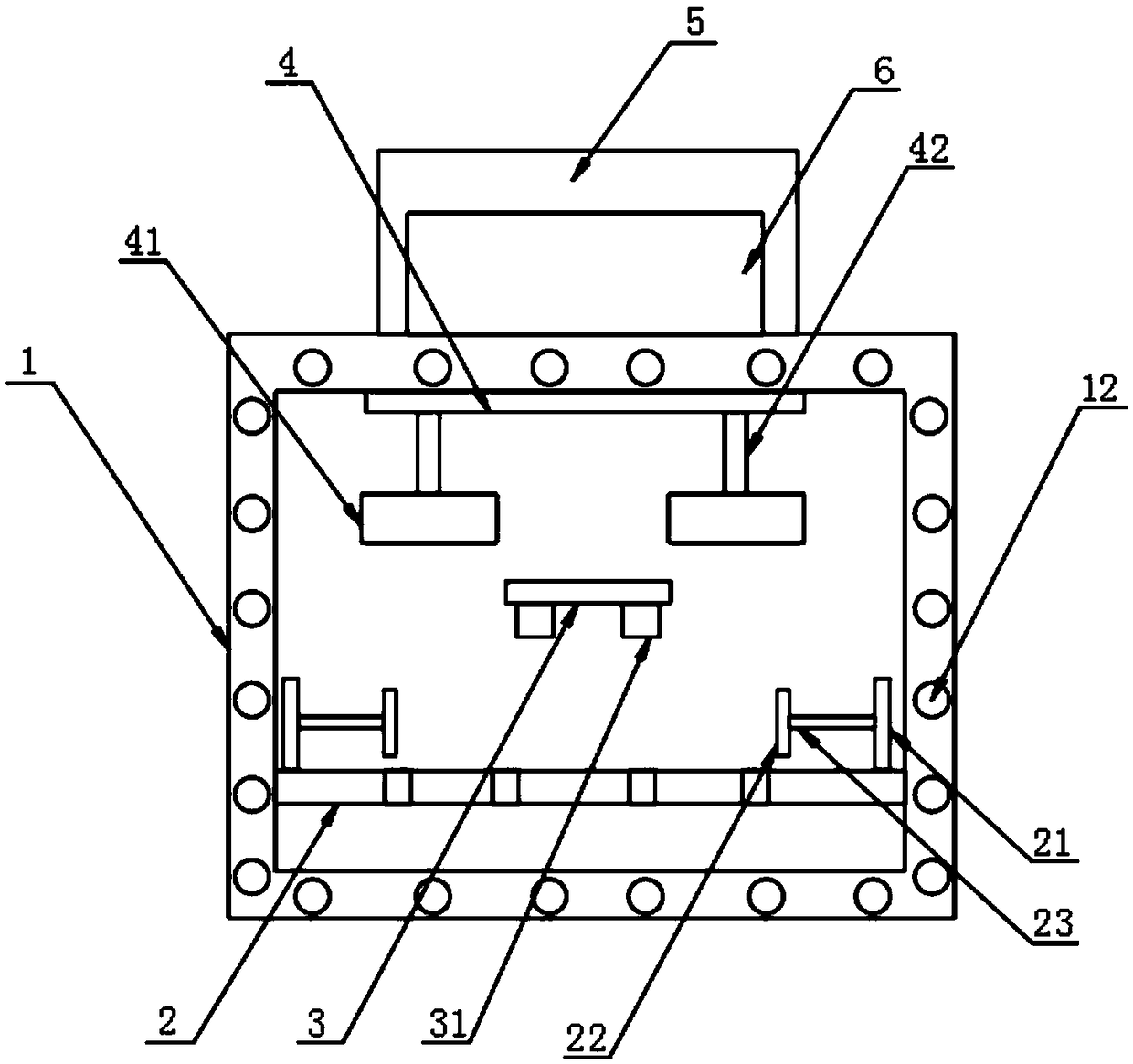

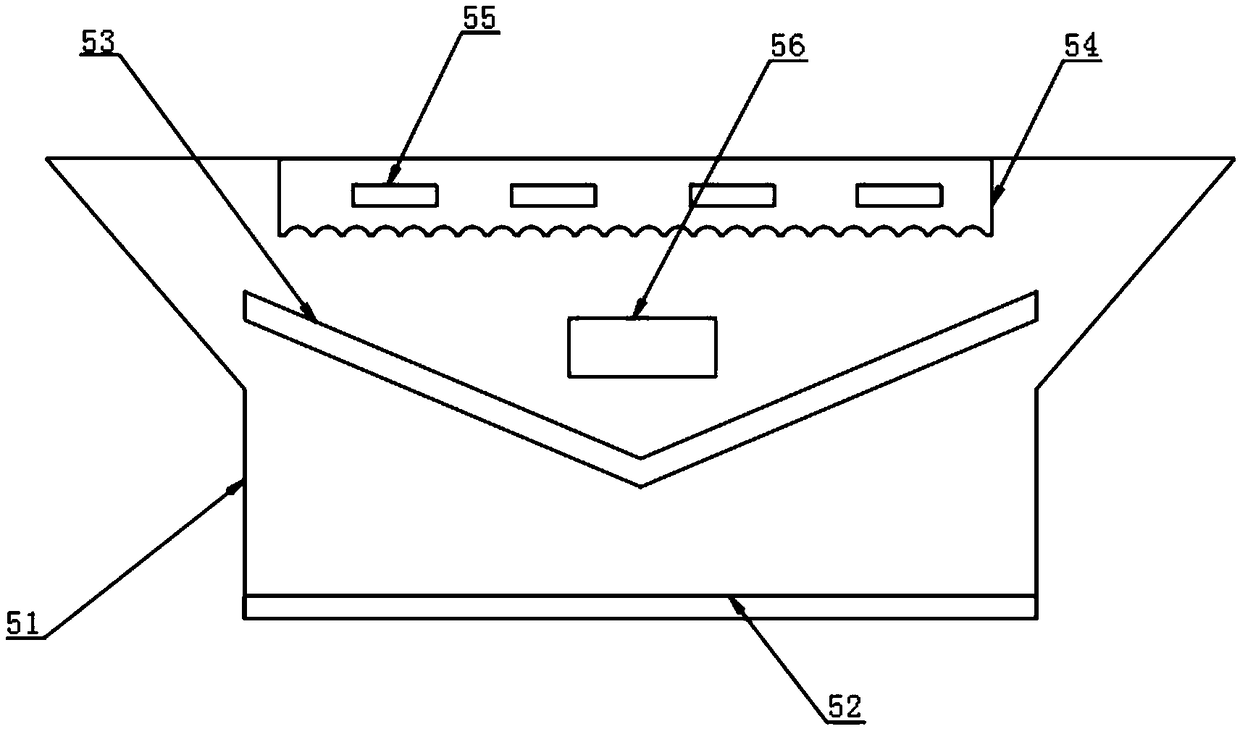

[0027] The present invention provides such Figure 1-3 A device for reusing water vapor in the drying system of pulp molded products and improving the drying efficiency of the system is shown, including a drying chamber 1, and a drying transmission panel 2 is arranged inside the drying chamber 1, and the drying transmission panel 2 The top is provided with a horizontal plate 3, the top of the inner wall of the drying chamber 1 is provided with a mounting plate 4, and the top of the drying chamber 1 is connected with a water vapor reuse device 5, and the water vapor reuse device 5 includes a collection shell 51. Ventilation plate 52, water storage tank 53, cooling pipe 54, refrigerator 55 and water pump 56, hot air fans 6 are provided on both sides of the water vapor reuse device 5, and a humidification chamber is provided on one side of the drying chamber 1 A humidification transmission panel 8 is arranged inside the humidification chamber 7 , and a communication chamber 9 is ...

Embodiment 2

[0031] A material inlet 11 is provided on one side of the drying channel 1, and a heating tube 12 is evenly arranged in the inner cavity of the drying channel 1, and the outer side of the heating tube 12 is filled with heat-conducting oil.

[0032] The inside of the dry transmission panel 2 is evenly provided with water holes, the top of the dry transmission panel 2 is provided with a side plate 21, the inside of the side plate 21 is provided with a splint 22, and between the side plate 21 and the splint 22 Electric push rod 23.

[0033] The bottom of the horizontal plate 3 is uniformly provided with blowing nozzles 31, and the blowing nozzles 31 communicate with the hot air blower 6 through a ventilation pipe.

[0034] The bottom of the mounting plate 4 is uniformly provided with pressure rollers 41 , and a hydraulic lifting rod 42 is provided between the pressure rollers 41 and the mounting plate 4 .

[0035] Beneficial effects of this embodiment: the heating pipe 12 works ...

Embodiment 3

[0037]The inside of the humidifying chamber 7 is provided with a fixed plate 71, the bottom of the fixed plate 71 is uniformly provided with a spray head 72, and one side of the fixed plate 71 is provided with a discharge port 73, and the discharge port 73 is arranged on the humidification transmission Outside the panel 8, a water storage chamber 74 is provided on the top of the humidification channel 7, the spray head 72 communicates with the water storage chamber 74 through a water pipe, and the water storage chamber 74 communicates with the water pump 56 through a water pipe.

[0038] The communication cavity 9 is hollow, and the drying transmission panel 2 passes through the communication cavity 9 and the humidification channel 7 in sequence to communicate with the humidification transmission panel 8 .

[0039] Beneficial effects of this embodiment: the spray head 72 sprays water mist to rehydrate and humidify the pulp molding, and at the same time the sprayed water mist ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com